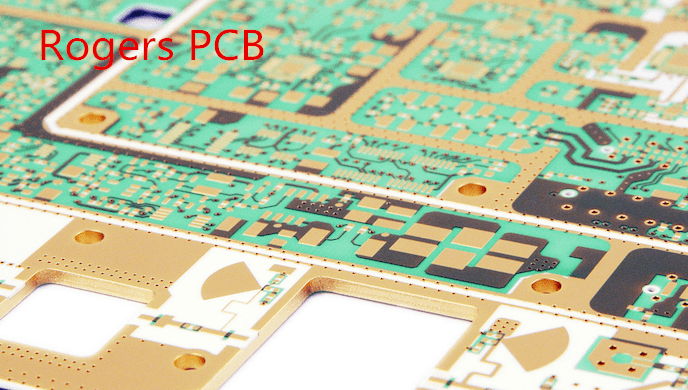

Technology is all about making necessary advancements that will influence and bolster the success of different technological inputs. In the Printed Circuit Boards (PCBs) industry, it continues to play out with the introduction of the Rogers PCB.

In this context, we aim at helping you understand all there is to the Rogers PCB. You will also discover the benefits and the reasons why many PCB manufacturers will advise that you use it in your PCB designs. Finally, we will let you know the top 5 Rogers PCB manufacturers in China. That way, you wouldn’t look farther when you want to design your next Rogers PCB.

What Is Rogers PCB Material?

We will start by saying that the essence of Rogers PCB is to reinvent and reposition the processes of manufacturing Printed Circuit Boards (PCBs). It is designed with the intent of performing better than the traditional FR-4 material.

Hence, the man idea behind the design of Rogers PCB is to provide better and more advanced features that will be used in the production of sturdy and long-lasting Printed Circuit Boards (PCBs).

About Rogers

Rogers is the company that manufactures Rogers PCB. The company centers its productions on the designing and manufacturing of laminate materials that will be used for the production of different types of Printed Circuit Boards (PCBs).

Besides, Rogers has one major goal, and that is to work on some of the inefficiencies of the traditional FR-4 material. By doing that, it hopes to chart the pathway for the all-around integration and use of its Rogers PCB in different PCB applications.

What Makes Rogers PCB Better Than the FR-4 Material?

We have continuously mentioned that the primary aim of the Rogers PCB is to make it easier for PCB manufacturers to make circuit boards. Of course, this is because of the advanced properties that the Rogers PCB has to offer.

So, what are those Rogers PCB properties that make it better than what we have had in the traditional FR-4 material?

1. Higher Frequencies

It is pertinent to mention that the traditional Flame Retardant Level 4 (FR-4) has limited frequencies. It is partly because of the copper foil lamination on both sides of the board, and mainly because of the epoxy composite/glass fiber components.

Instead of basing on the limited and lower frequencies that we have been seeing on the FR-4 material, the Rogers PCB offers a higher variant. This is because the manufacturer, Rogers will offer FR-4 core and additional copper laminate.

The advanced FR-4 core used here aids in the provision of higher frequencies, especially because of the inputs of PTFE (Teflon) reputed for the high frequency.

2. Wider Range of DK Values

In the comparison of the Rogers PCB and the FR-4 material, one of the most outstanding properties is the advanced DK values.

The Rogers PCB is famed for the wider range of DK values that it offers. That makes it better than the limited variant tenable in the FR-4 material.

Besides, the outstanding effects of the Rogers PCB are evident when it tested in line with impedance stability.

For example, the Dielectric Constant (DK) value of the Rogers PCB can be as high as 10.2.

3. Higher Costs; Higher Values

If there is any other reason why you mustn’t hesitate to use the Rogers PCB, it is the higher costs. Of course, it is understandable that you may be working on a budget. Hence, you may not have all the funds to spend on getting the PCB design done.

However, Rogers, the manufacturer of the Rogers PCB promises to offer higher quality with the board. And from what we have seen so far, the company is keeping to that promise by providing higher values in all ramifications to equate the higher costs of the Rogers PCB.

4. Less Variation

It is not out of place to check for the temperature management and sustenance of Printed Circuit Boards (PCBs). It helps to give insights into what must be done to ensure that the circuit board is operating in top shape at all times.

On the one hand, the FR-4 material has more variation when it comes to the temperature management of the circuit board.

5. Lower Signal Loss

It is rather sad for a circuit board to lose signals when it ought to have been working hard to get more. That has always been the case with the FR-4 material. That is also the basis for the use of the Rogers PCB to ensure that things go on as scheduled by having sufficient signals on the circuit board.

The major reason why the Rogers PCB does better in this regard is that it uses the lower Dissipation Factor (DF). It is the lower DF that makes it harder for the Rogers PCB to suffer from higher signal loss, as has been the case with the FR-4 material.

Features of the Rogers PCB Material

Before you look for where to buy Rogers PCB, we would like you to understand the features. Those properties will give you considerable insights into how the Rogers PCB towers higher than the other forms of laminate materials used in the designing and manufacturing of Printed Circuit Boards (PCBs).

Better Thermal Management

It is easier, cost-effective, and faster to manage the thermals of circuit boards if the Rogers PCB were used in the same.

That also implies improved efficiency and lower costs of managing the thermal points on a Printed Circuit Board (PCB).

Affordable PCB Fabrication

Fabricating Printed Circuit Boards (PCBs) may be costly because of some reasons, such as the manufacturer and the type of PCB that is to be manufactured.

However, the costs associated with the fabrication of Printed Circuit Boards (PCBs) will be significantly reduced when the Rogers PCB is used.

Higher and Wider DK Values

The values of the Dielectric Constant (DK) tend to be higher and wider when the Rogers PCB is the basis for designing the Printed Circuit Boards (PCBs).

For example, you can get or derive up to 10.2 Dielectric Constant (DK).

The other features and advantages of the Rogers PCB are:

- Significant improvements in the impedance control

- Reduction of the electrical loss on the PCB

- Reduced and lower outgassing for space applications

The Reliable Rogers PCB Manufacturers in China

Finding a Rogers PCB manufacturing company may take time but it’s worth the effort. You are confident that when you get the right manufacturer, it will be easier for you to outsource your next Rogers PCB designs.

We mustn’t leave out the fact that the Rogers PCB manufacturer may not always have all the things you wanted but the few it has will make the project successful.

That said, here are the five (5) major Rogers PCB manufacturers that you can look up in China:

1. RayMing Technology

RayMing Technology, otherwise called Ray PCB is one of the budding and one of the largest PCB manufacturers in China. The company has many years of experience, excellent and skilled staff, as well as high-precision PCB materials as some of the ways it makes your Rogers PCB design good.

Beyond that, RayMing Technology has a knack for quality as that is evident in the multiple reviews and feedbacks coming from the previous clients.

Large Portfolio

Ray PCB has one of the diversified and larger portfolios of Rogers PCB. For example, it offers many types of Rogers PCB design, including Rogers 3003, Rogers 4350B, and RT5870.

Varied Designs

Aside from designing and manufacturing Rogers PCB, Ray PCB also deals with the production of some other variants and options of the Rogers PCB.

The most notable among these is the Mix-Laminated Printed Circuit Boards (PCBs).

High-Speed

The last thing you would want on your Rogers Printed Circuit Board (PCB) is for it to lag in speed.

That can be fixed and high-speed will become optimum when you choose a Rogers PCB manufacturer, such as Ray PCB.

In addition to the high-speed performance, the company also offers a high-efficiency performance of the Rogers PCB in both the wired and wireless communication sectors.

2. PCBGoGo

As the name suggests, PCBGoGo is the rallying point of customers that want to have their Rogers PCB jobs done and in time too.

The company has through consistency, an eye for details, and over 10 years of experience been designing and manufacturing some of the best Rogers PCB.

Some of the points and reasons why PCBGoGo should be your favorite Rogers PCB manufacturer are:

Competitive Pricing

The place of prices of Rogers PCB cannot be underestimated in the selection of the best manufacturer.

Of course, PCBGoGo is committed to offering you one of the best quotes in the Rogers PCB niche. That way, you will get to spend less on more quality designs.

High-Quality

PCBGoGo places a premium on the quality of the Rogers PCB design. For example, the company uses high-quality PCB laminate especially the ones that pertain to aluminum, FR-4 material, and Rogers PCB.

3. Fastline Circuits Company Limited

The selection of the best Rogers PCB manufacturer in China isn’t only about the quality of the Rogers PCB. At other times, the insulation processes and other hitherto ignored properties need to be considered too.

That is where the Fastline Circuits Company Limited comes in to steal the show as one of the best Rogers PCB manufacturers in China.

This Guangdong, China-based Rogers PCB manufacturer offers extensive services such as:

- The use of the Delay Pressure Foil processing technology

- Using Rogers as the base material of the Printed Circuit Board (PCB)

- Maintaining V0 Flame Retardant (FR) properties

- Leveraging Organic Resin as the insulation material for the Rogers PCB

4. PCB Sino

Some Rogers PCB manufacturers in China can be faster than the others are without compromising on quality.

If the project is needed ASAP and you are not sure you can spend more time waiting for the longer turnaround time; it makes to use the services of a manufacturer with a quick turnaround.

PCB Sino is a reliable Rogers PCB supplier and manufacturer in China. With an estimated turnaround time of 24 hours for the prototypes, we are sure that this company will deliver faster.

Aside from the facilitated Rogers PCB design and production, this company has some other remarkable offers to make.

Here are some of the things you stand to benefit if PCB Sino were to design and manufacture your Rogers PCB:

- Component sourcing

- Conducts different types of testing, such as Function Test, BGA X-Ray Test, and AOI Testing.

- SMT and wave soldering

5. Global Sources

Global Sources is a brand that focuses on the manufacturing and supplies of Rogers PCBs.

Due to the extensive services, it offers in that regard, the company has different features and use cases that will fit into what you need.

Here are some of the capabilities of Global Sources as one of the leading Rogers PCB manufacturers and suppliers in China:

- Flexible Minimum Order Quantity (MOQ) that ranges between 1 and 3

- Many certifications that point to the excellent of the Rogers PCB services it has to offer.

- Faster response rates

- It can deliver the Rogers PCB in good time courtesy of the 20-day maximum lead time.

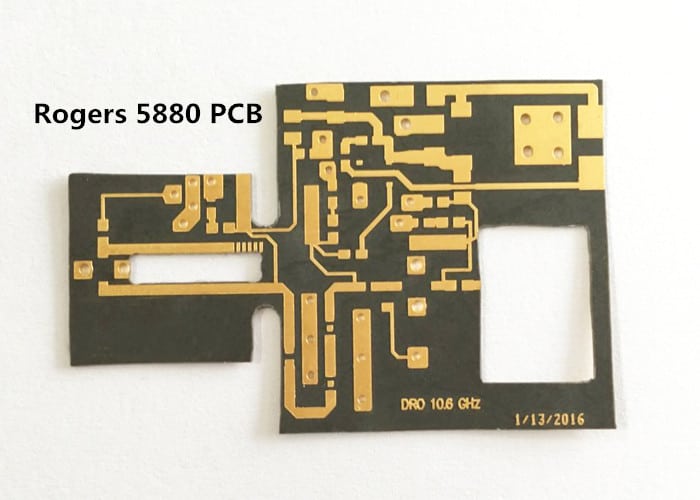

Rogers 5880 Price

The Rogers 5880 is one of the classifications and variants of the Rogers PCB. It makes use of the PTFE high laminates. That in turn, reinforces the operations of the glass microfibers.

Some of the benefits of Rogers 5880 are that it can be used even in high moisture environments and use cases, and it well-shaped. Besides, the Rogers 5880 has a higher resistance to reagents and solvents, just as it reduces the loss of electrical currents.

You can always request a quote from Rogers PCB manufacturer so you will have an idea of what it will cost you to design the Rogers 5880.

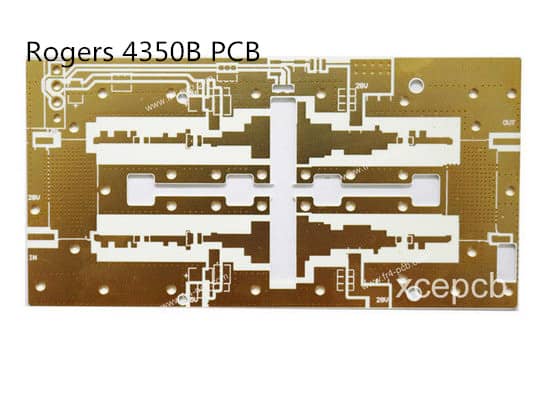

Rogers 4350

The other variant or type of the Rogers PCB is the Rogers 4350. It is mainly used when there is a need for high-volume and high-performance applications of the Rogers Printed Circuit Boards (PCBs).

Final Words

Rogers PCB offers better precision, speed, and accuracy when using Printed Circuit Boards (PCBs) in different electrical devices and components.

Always endeavor to use the services of the leading Rogers PCB manufacturers in China, such as the ones on the list above.

That way, you are sure that the outcome of your Rogers PCB design will be remarkable, excellent, and will serve the purpose for which it is designed.

Comments are closed