As a PCB designer, you may be seeking materials that can effectively handle high-frequency microwaves. One option to consider is Rogers PCB, which is known for its excellent performance. The Rogers RO4350B and RO4003C are popular choices among designers. However, you may be wondering what sets Rogers PCB apart from other options such as Teflon, RF, and high-frequency PCBs. To learn more about these materials and how they compare, read on.

What is Rogers PCBs?

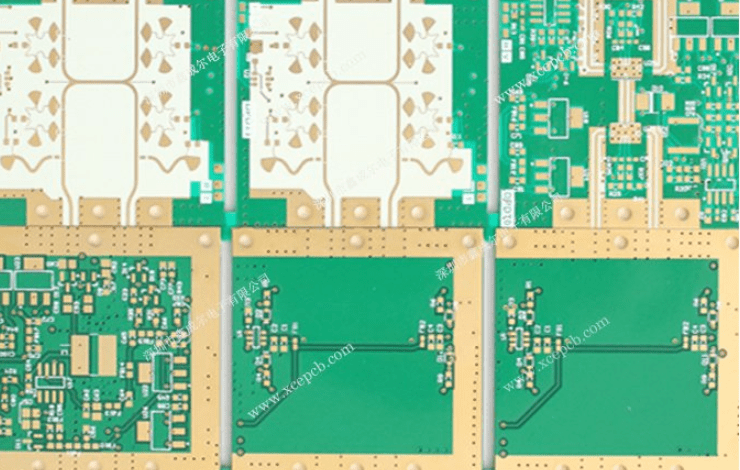

Rogers PCBs are those that utilize Rogers laminates. It is a type of material produced by the Rogers company for use in the creation of Printed Circuit Boards. While PCBs are typically made from FR4, a composite of glass fiber and epoxy resin, Rogers offers FR4 laminates with improved high-frequency properties, including Teflon. In addition, Rogers has a variety of materials specifically designed for high-frequency Printed Circuit Boards, which have a relative permittivity ranging from 2.3 to 10.2 and low dielectric losses.

These materials include:

- RT/duroid series of fluoroplastics

- The RO3000 and RO4000 series of reinforced fluoroplastics

- ULTRALAM 2000 reinforced laminates

- Hydrocarbon ceramics TMM

The manufacturing of printed circuit boards (PCBs) can involve using materials of various thicknesses and metalizing them on one or both sides using electrodeposited or rolled foil made of copper, brass, or aluminum. In addition, Rogers materials, which have high loss tangent and dielectric constant values, can be used in combination with FR4 in the production of PCBs.

- Minimal loss of electrical signals during operation

- Minimum loss of dielectric material

- Efficient thermal management

- Wide range of dielectric constants

- Low outgassing, suitable for use in space

- Good impedance control

Electrical Insulation In Relatives Of Rogers PCBs

The Rogers Printed Circuit Boards (PCBs) are equipped with ceramic hydrocarbon lamination and a dielectric layer for insulation. This layer acts as a poor conductor for electrical connections and transformations, making it an effective insulating material. In addition, it is designed to operate at frequencies ranging from 500 to 10 GHz.

Some key points to remember about HF PCBs include:

1. RF Comparison With Microwave

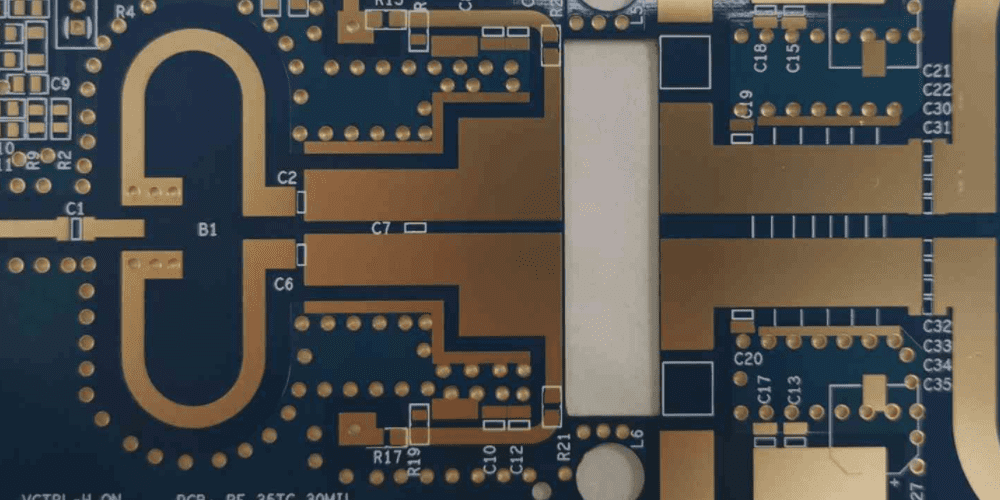

RF and microwave PCBs are specialized circuit boards that are fabricated using a fluoroplastic base material. These PCBs are either single-sided or double-sided and are designed to have a low dielectric constant (less than 3) and minimal dielectric losses (smallest tangent). Additionally, these PCBs are known for their high thermal-mechanical stability. Currently, Rogers materials are the most commonly used materials for meeting these requirements in RF and microwave PCBs.

2. Teflon PCB

PTFE, a type of polymer, is commonly used in the production of Printed Circuit Boards. It is also known by its trademark name, Teflon, which is a brand used by DuPont for a variety of polymer products. Teflon-based PTFE materials are often used in the creation of PCBs, also referred to as Teflon PCBs.

3. Rogers Comparison With FR4

There are several differences between FR4 and Rogers materials.

- Rogers material is more expensive than FR4 material

- Rogers material has superior high-frequency performance compared to FR4 material

- Rogers material has lower signal losses, while FR4 material has higher signal losses due to its greater dissipation factor

- Rogers material has a range of dielectric constants and is better for the stability of impedance, while FR4 material has a smaller value of dielectric constant

- Rogers material is more stable in temperature management compared to FR4 material

What Is The Price Or Cost Of Rogers PCB?

It is not possible to accurately price higher-performance PCBs using online calculators because they are too complex. These calculators can only handle simple boards with 1 to 8 layers. Instead, a custom quote must be obtained by engineers who review the design and requirements of the PCB. Pricing for PCBs can vary based on a range of factors, including the specific material used, such as Rogers RO3000 or RO4003C. It is also worth noting that PCB prices may be significantly higher in North America and Western Europe compared to those in China. In some cases, a quote from a PCB shop in these regions may be ten times more expensive than one from a Chinese company.

• Laminates of RO4350B™

Rogers Ro4350b is a type of high-frequency material used in commercial applications that require excellent Radio Frequency performance with low-cost circuit construction. It is made of glass fiber-reinforced hydrocarbon/ceramic laminates and can be processed using standard FR4 (epoxy/glass) methods at affordable prices. Ro4350b is well-suited for Radio Frequency microwave equipment, particularly in the filter designs, coupling set-ups, and transmission lines with controlled impedance. Its minimal dielectric dissipation and stable dielectric constant across a broad frequency band also make it a good choice for Wideband equipment.

In terms of drilling, Ro4350b provides superior bore surface quality and does not significantly increase in roughness when using worn drills, unlike epoxy/glass materials. The coarseness of material holes typically ranges from 8 to 25 micrometers, no matter how many passes are made (as many as eight thousand passes were measured). The coarseness is influenced by the magnitude of the ceramic restoration and offers a favorable topography for adhering to the hole wall. Ro4350b can also be drilled using the same conditions as epoxy or glass plates and is capable of resisting damage from strikes of over 2,000.

One of the key benefits of Ro4350b’s thermal expansion coefficient is its similarity with copper, making it compatible with this common circuit material.

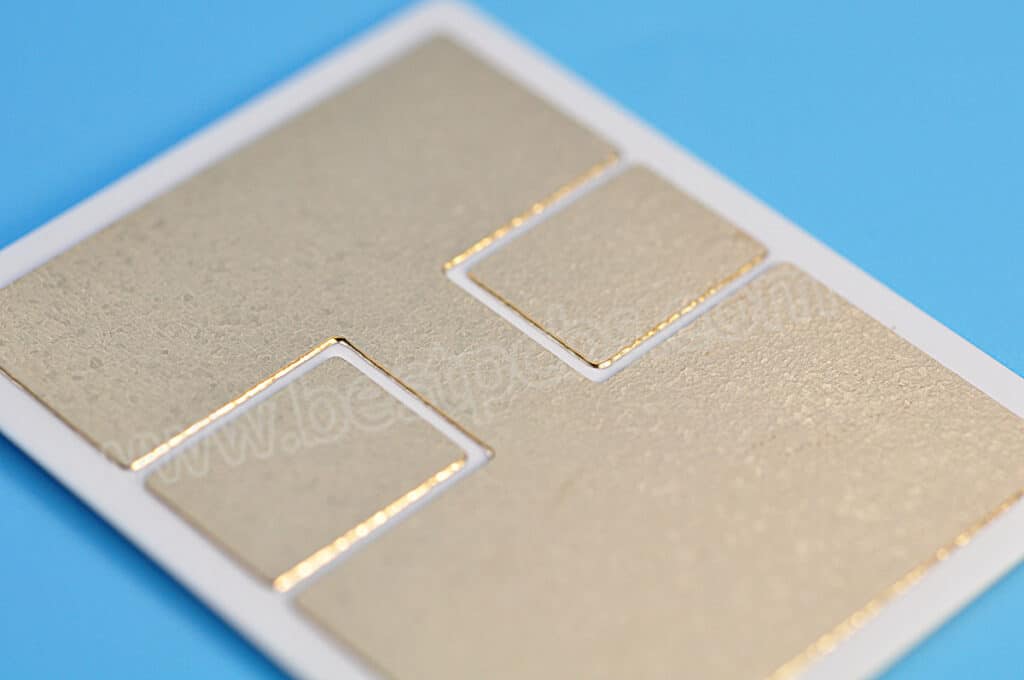

• Dimensional Stability

RO4350 laminates are ideal for use in the fabrication of PCB boards with multiple layers and a mix of dielectric substances due to their low CTE along the vertical axis. This property ensures that through holes maintain their quality, even under the stress of thermal shock. The material has a high glass transition temperature of 280°C, making it consistently stable under all temperature conditions in a circuit. Additionally, It is easy to convert RO4350 laminates into PCBs applying usual FR4 processing techniques, and it doesn’t require any special treatment like sodium etching like some high-performance PTFE materials. This heat-stable, rigid laminate can also be handled by automated washers and systems which are utilized to treat the surface of copper.

• Availability

There is a range of RO4350b laminates that are currently on the market, made with either 1674 or 1080 fabric material. These options all adhere to the uniform laminated electrical efficiency specifications. The RO4350 laminates were created specifically as a replacement for RO4350b and utilize RoHS_compliant flame-resistant technology to achieve Underwriters Laboratories Standard 94V-0 validation. Additionally, these laminates also meet the standards set by IPC-4103/10(standard published by the Association Connecting Electronics Industries), for Rogers-4003C and IPC-4103-11 for Rogers-4350b when used as single sheets.

Guidelines for Producing Rogers PCB

The RO4350B material has been designed to deliver performance with high frequency that is similar to that of glass bases with a Polytetrafluoroethylene layer but with the added benefit of being able to be easily fabricated with glass or epoxy laminates. This thermoset material is made with carbon-hydrogen compound/ceramic-glass composite and it transforms at a high temperature of 280 degrees Celsius.

One of the key advantages of using RO4350 instead of Polytetrafluoroethylene-based microwave substances is that it does not require any special preparation vias during processing. So, the cost of working with RO4350 circuits is similar to that of glass or epoxy laminates. When handling RO4350b Bi-plates, it is generally recommended to use the same methods of treatment and parameters as those used for glass or epoxy plates.

• PCB Material

To ensure smooth, burr-free input and output surfaces, it is important to use smooth and inflexible materials such as aluminum or hard laminated panels (ranging in thickness from 0.254 to 0.635 millimeters). While most standard substances (they may have an aluminum coating or not) can be used, using the recommended input materials will provide the best results.

• Battery Height

To ensure proper drilling, the combined diameter of input material and substrate penetration should not overreach 70% of the length of the groove. This means that the material being drilled should not be too thick to the length of the groove.

• Perforation

It is generally best to avoid surface speeds above 500 surface feet per minute and chip loads lower than 0.05 millimeters (0.002 inches). These conditions can cause problems and try to avoid them ver possible.

The Specific Inductive Capacity Of The RO4350B

The dielectric constant is a measure of a material’s ability to conduct electricity, relative to that of a vacuum. When designing and fabricating PCBs, it is important to consider the dielectric constant of the material. For example, the dielectric constant of Ro4350B is 3.48 plus minus 0.05, while the dielectric constant of the design is 3.66.

• Wire Bonding Handling for RO4350 PCB

Wire bonding is a process that allows you to connect equipment of semiconductor and integrated boards or circuits to packages during fabrication, and can also be used to interconnect different PCBs. There are two main methods of wire bonding: diffusion bonding and fusion welding. This technique is useful for a variety of applications in the electronics industry.

• Fusion Welding

It is the process of melting circuit boards and metal altogether using various techniques such as laser welding, soldering, arc welding, gap welding, or resistance welding. These methods all work to create a strong, seamless connection between the materials.

• Diffusion Bonding

There are various methods of creating joints without the use of welding, and these are known as diffusion bonding techniques. Some examples of these techniques include compression and thermosonic bonding.

Instructions for Circuit Board Fabrication while designing Rogers PCB

Use the following tips to assist you in the construction of Rogers 4350B PCBs:

• Inner layer preparation

When working with the Rogers 4350B, you have the option of using either pinless, depending on the circuit’s capabilities and your last requirements of registration. For thinner cores, chemical processing is recommended, while mechanical processing is better for thicker cores. Additionally, be sure to follow the guidelines for the adhesive when choosing a CuO or other oxide treatment.

• Drilling

To drill, you can utilize either standard entry or exit materials. Keep in mind that the speed of drilling should be kept below 500SFM.

• Deposition of Metal

When performing metal deposition on RO4350B, no special preparation is required. You may also consider using copper plates when imaging boards with high aspect ratio holes

• Processing of Outer Layer & Copper Plating

The outer layer of a circuit board can be treated with a variety of processes, including tin plating, electrolytic plating, panel processing, & copper plating. Once the plating process is complete, the laminate can be further processed using the method of SES. This allows for the creation of a durable and reliable circuit board.

• Storage

To ensure the longevity and integrity of your laminates, it is important to store them at standard room temperatures between 10 and 30 degrees Celsius. Additionally, it is crucial to protect the laminates from excess humidity, as this can lead to the oxidation of materials. By following these simple storage guidelines, you can maintain the quality of your laminates.

Final Thoughts

We have provided an overview of the Rogers 4350B printed circuit board. This particular PCB is known for its high-frequency and low-cost capabilities. We have also outlined its various specifications and features. Do you still have any further questions? Don’t hesitate to reach out to us for more information.

Comments are closed