Printed Circuit Boards keep being the foundation of most electronic products. These boards serve as the building block of electrical devices. PCBs are widely used by small businesses and large businesses. However, small businesses and startups face challenges when they need to assemble PCBs. For instance, these businesses need an in-house team to create large inventory.

This is why Turnkey PCB assembly is there to provide solutions to these problems. In this article, we will discuss Turnkey PCB vs Turnkey PCB assembly.

What is Turnkey PCB?

Turnkey PCB is a ready-made circuit board for PCB users. Most times, the PCB manufacturing process takes a lot of time. Also, PCBs serve both commercial and household purposes. There is an increasing need to get fast PCB service. Therefore, the Turnkey PCB is an ideal choice for most PCB users.

The most crucial activity is developing and verifying the prototype. The development of the prototype will determine if you can fabricate a PCB. Also, it will affect the timeline of your PCB delivery. This makes PCB manufacturing and designs very crucial. Therefore, opting for turnkey PCB becomes an important consideration.

A single manufacturer handles the fabrication processes of a Turnkey PCB. Therefore, the manufacturing of this PCB doesn’t require several iterations. Also, if you are looking forward to minimizing production costs, the turnkey PCB is for you. For a Turnkey PCB, you don’t need to dedicate your whole time to the manufacturing process. This is because your Turnkey PCB manufacturer will handle everything.

Turnkey PCBs are often fabricated with quality in mind. Rather than outsourcing various aspects of production, a company does it all. Turnkey PCBs are widely used in several applications. Also, these PCBs are available in different types and sizes.

————————————————————-

Request PCB Manufacturing & Assembly Quote, Pls Send PCB File to Sales@raypcb.com Now

————————————————————-

What Is Turnkey PCB Assembly?

This is an electronic assembly solution that provides a cost-effective way to fabricate PCBs. Furthermore, this PCB tests PCBs for functionality. Also, Turnkey PCB assembly offers short lead times for these services.

The word “Turnkey” simply means any service or product available for a buyer to operate. As regards PCB assembly, Turnkey assembly ensures your supplier handles all production processes of your PCB. Here, the supplier gets all components and parts of your PCB and assembles it.

Also, Turnkey PCB assembly incorporates powerful equipment and cloud-based software to fabricate PCBs. Turnkey PCB assembly handles every production stage rather than outsourcing bits of manufacturing via several vendors. Also, this assembly offers a one-stop process.

Turnkey PCB assembly offers the following:

- Components and parts sourcing

- Prototyping

- Design assistance

- Assembly

- Testing

- Obsolescence management

- Aftermarket services

PCB turnkey incorporates all these stages in an electronics contract manufacturing service. Also, turnkey PCBs are available at your doorstep and ready for use right there. PCB assembly services providing turnkey solutions ensure that your PCB meets your requirements.

Electronic manufacturing services (EMS) companies that provide turnkey solutions should have the capabilities needed to fabricate your board well. Also, Turnkey PCB assembly services carry out all the production processes. From the provision of circuit boards to their fabrication, Turnkey PCB assembly is responsible.

Sometimes, a PCB assembler might help to develop plans and parts lists to achieve your project. Also, a Turnkey service can save you a lot of stress, particularly if you’re a newbie in the PCB industry.

What are the Advantages of Turnkey PCB assembly?

Turnkey PCB assembly provides a wide range of benefits to businesses. Also, the services provided are beneficial to young startups in the PCB industry. Therefore, we will discuss the advantages of Turnkey PCB assembly.

Single point of contact

Startups need to quote and confirm their PCB design files with different suppliers. Therefore, it is very stressful to work with several vendors, especially small startups. If care isn’t taken, one error can cause delays and the supply of low-quality items across the PCB chain.

However, you can prevent this by opting for a Turnkey PCB assembly service. Here, you only need a single contact. Also, a single supplier carries out all the production processes. This means you can communicate your needs to your supplier efficiently.

High-quality product and services

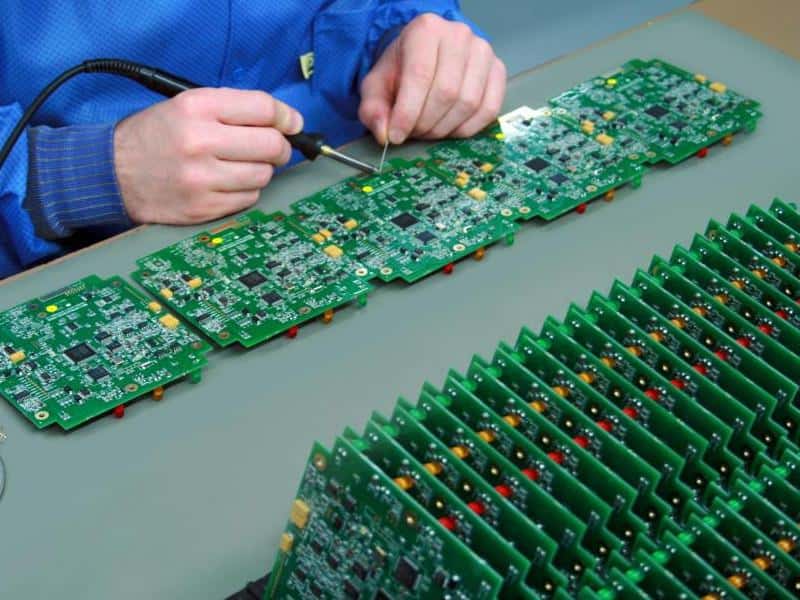

These are great advantages you get to enjoy when you opt for a Turnkey PCB service. Turnkey PCB assembly services work with a team of experts in PCB manufacturing. Also, you will get high-quality PCBs with fine soldering. Professional PCB assemblers make use of high-quality laminates and solder resist. Also, they use good silk-screen techniques

You can forgo silk-screen printing to minimize costs. However, it is better to print your startup’s logo on the PCB. Also, Turnkey PCB assembly uses SMT components to enhance the reflow oven. This assembly solution only offers quality.

Error identification

Timely detection of errors can help to save costs to a large extent. One thing about Turnkey PCB assembly services is the early detection of defects in the fabrication processes. However, ensure you submit a netlist to your assembler. This helps your assembler to examine your specifications to be certain of the application.

If there is any defect, you can easily correct the design. Errors can jeopardize your startup’s production. Therefore, it is advisable to detect these errors early. Early error identification is a cost-saving benefit of Turnkey PCB assembly.

Save time and cost

You are contacting a single source and this source will handle all the stages of production. Since you are only contacting a single source, you can devote your time to other needs of your startup. The faster lead times and the ability to track orders in real-time save you time. Also, you can save costs since you are channeling your whole resources to a single supplier. This reduces the time and cost of dealing with different suppliers.

Types of Turnkey PCB Assembly

The two varieties of Turnkey PCB assembly are full and partial.

Partial Turnkey PCB Assembly

This type of Turnkey PCB assembly only outsources part of the assembly process. Here, the assembler handles part of the supply chain. Also, the partial Turnkey PCB assembly works with a tech developer. This personnel obtains and packages materials for delivery.

A partial Turnkey PCB is ideal for businesses that have the necessary parts on hand. In this regard, this service will help to save costs. However, the full turnkey service is better if you don’t have the required parts.

For a partial Turnkey service, a contract manufacturer works with the in-house supply chain of the customer. The manufacturer gets the components and parts needed for the circuit boards. Also, the manufacturer will handle the assembly.

Full Turnkey PCB assembly

This type of assembly is in charge of the whole production process. From component sourcing to design and prototyping. It takes care of all the stages of PCB production. Therefore, it is an ideal choice for businesses that don’t want to involve themselves in the production process. Also, it is great for businesses that don’t know where to get the necessary parts.

Also, a full Turnkey assembly service will create the circuit order and source the parts. However, you will need to provide:

- Gerber files

- Packaging and shipping details

- A bill of materials

- Product dimensions

A full PCB turnkey assembly can improve your experience when getting PCBs. Furthermore, this assembly eliminates communication challenges that result from dealing with many suppliers. It is a single-source approach that saves cost and time.

————————————————————-

Request PCB Manufacturing & Assembly Quote, Pls Send PCB File to Sales@raypcb.com Now

————————————————————-

Turnkey PCB Assembly Solutions and Technology

Mechanical assembly

Turnkey PCB assembly offers mechanical assembly. This involves positioning PCB elements in an assembly line. Furthermore, mechanical assembly describes PCBs fabricated this way.

Cable assembly

This refers to a set of wires assembled into one unit. The cable assembly may transmit electricity. Also, it is widely used for transmitting informational signs. In addition, it supplies electricity to wires while controlling them in a bundle.

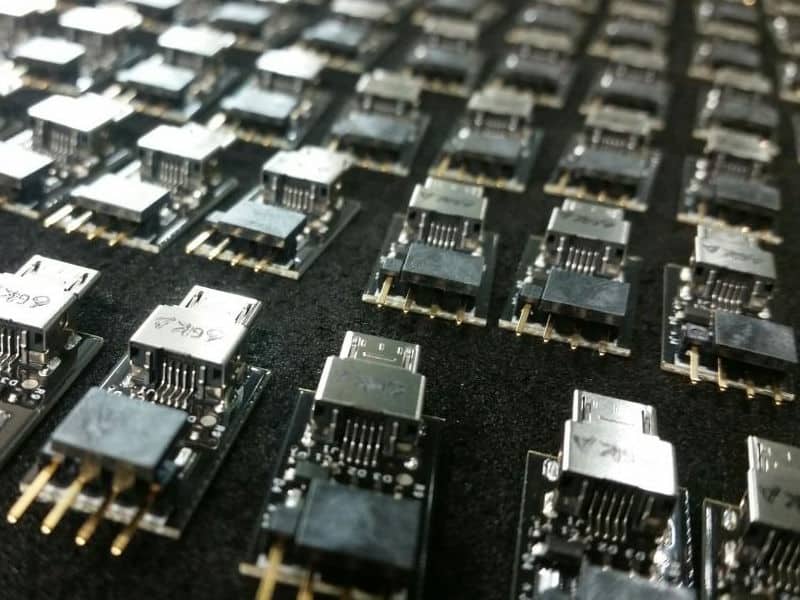

SMT Assembly

Surface mount assembly involves mounting components on a PCB surface. SMT assembly uses advanced technology to place these components. The pick and place machine is responsible for placing these components.

Axial Horizontal Assembly

Axial-leaded elements are primarily used to reduce short distances on a PCB. The Axial horizontal assembly is available in two configurations. These configurations are surface-mount and right-angle through-hole.

BGA Assembly (Ball Grid Array)

Ball Grid Array is another surface mount technology bundle. This type of technology is ideal for Integrated circuits with several hooks. Also, BGA is a high-density method and cheap packaging ideal for bringing out some of the greatest circuit boards.

Radical vertical assembly

This assembly involves placing parts on a bare board when the PCB area is restricted. Parts arrangement is completed vertically on the PCB. In this regard, leads are at one end of this component.

Lead-free soldering

This involves soldering PCBs with the use of leads. Lead-free solders may have aluminum, zinc, and other metallic traces. However, it is crucial to know that soldering containing hints may produce fumes and dust that may be hazardous.

Box-build assembly

Also known as systems integration. The box detects some circuit boards meeting in a cupboard filled with cables. Also, it could identify an integrated electromechanical system with pneumatics and electronics.

What Does Turnkey PCB Assembly Offer?

Turnkey PCB is an already made PCB for users. The whole manufacturing process of this type of PCB is carried out by a one-stop PCB service. Turnkey PCB assembly services are responsible for the PCB production processes. They offer a lot of functions like:

PCB Prototyping

In those days it was very difficult to get a PCB manufacturer that would take prototyping orders. This was because some manufacturing equipment couldn’t handle small orders. Also, it was costly and wasteful to design a PCB prototype. Therefore, only a few accepted prototype orders for high prices.

However, PCB manufacturers now use sophisticated software. This software can design prototyping for small orders. Designers can upload their BOMs and design documents into an online portal. Also, the delivery of these prototypes takes a few days.

PCB Manufacturing

Also, turnkey PCB assembly offers PCB manufacturing. Large quantity requirements were usually the trend. However, those restrictions aren’t applicable again. Some PCB manufacturers take orders from one to 10,000. Although quantity still influences unit cost, you can get affordable prices for small orders.

Some manufacturers offer online pricing tools. Also, this helps determine the cost for each PCB at any quantity. Also, this helps to calculate capital requirements. Online tools allow you to keep track and give a report on your project anytime.

Electronic device assembly

In Turnkey PCB assembly, the manufacturer handles all the production processes. This means that this manufacturer can assemble your electronic device. Your manufacturer can help you with component sourcing. This makes the whole process seamless. Opting for a Turnkey PCB assembly means that all the production processes occur in a place. Therefore, this reduces the risk of errors or shipping delays.

Testing

A turnkey PCB assembly service verifies the functionality of the finished PCB. Testing is an important aspect of turnkey PCB manufacturing. Since a single manufacturer is responsible for the whole production process, early detection of errors is possible. However, a manufacturer can achieve this through proper testing.

There are different methods of testing the performance of a PCB. The X-ray and optical inspection methods are very effective.

Inventory storage and management

This is another function of Turnkey assembly. After fabricating the Turnkey PCB, the assembler stores the PCB in a certain place. Your PCB assembler is responsible for keeping and managing your inventory.

System integration

Placing your order is very important. This is the only way a Turnkey PCB service can fulfill our order. You can place your orders manually. However, it is more ideal to go for a manufacturer with software that can integrate with ERP systems via API. Application Programming Interface (API) means that orders can be automatically shipped.

What are the Differences: Turnkey PCB vs Turnkey PCB Assembly?

Turnkey PCB is the bare board used for turnkey PCB production. On the other hand, Turnkey PCB assembly involves the placement of electronic components on the bare board. For a PCB assembly, a bare PCB board is necessary. On this board, the manufacturer will assemble all electronic components on the board.

Also, Turnkey PCB assembly deals with all the stages of production. Turnkey PCB assembly uses different kinds of mounting technology. SMT technology is the most common method. This is because it is more advanced and requires less time. It involves placing electronic components on a PCB surface via an automated machine.

However, the through-hole technology is another method used by Turnkey PCB assemblers. Turnkey PCB assembly uses either SMT or through-hole technology. Also, it uses mixed technology. This is the combination of SMT and through-hole technology.

————————————————————-

Request PCB Manufacturing & Assembly Quote, Pls Send PCB File to Sales@raypcb.com Now

————————————————————-

Testing Methods Used for Turnkey PCBs

Testing is an important aspect of PCB manufacturing. Turnkey PCB assembly services offer testing and inspection services. These assemblers make use of different testing methods discussed below:

AOI (Automated Optical Inspection)

AOI utilizes two 3D cameras or a 2D camera to capture images of the circuit board. Then it compares the images of the PCB to a detailed schematic. If the PCB doesn’t match the schematics, this implies an error in the PCB. Also, AOI is ideal for identifying errors early. However, it doesn’t cover all the PCB parts. Therefore, it is advisable to implement AOI with other testing methods.

X-ray inspection

The automated x-ray inspection is an advanced way of testing PCBs. In this test, an X-ray machine identifies the defects during the manufacturing process. There are 3D and 2D x-ray inspections. However, 3D provides a faster testing period. Also, it is more advanced than 2D X-ray inspection.

X-ray testing examines the elements hidden from view. It checks for connections and BGA packages. Also, X-ray inspection requires experienced and trained operators.

Functional testing

You can pair functional testing with other testing methods. Functional testing needs external pieces of equipment and fixtures. This testing consists of a series of tests for verifying the functionality of a board. Functional testing detects manufacturing errors that impact reliability. Also, it checks for defects like missing components and solder connections.

Factors that Determine the Cost of Turnkey PCB

The cost of turnkey PCB varies based on several factors. These factors contribute to the variation in the cost of turnkey PCB.

Board Quantity

The quantity of the board you order will influence the cost of your turnkey PCB. When you order a large volume of PCBs, get ready to pay more. Your manufacturer will use more resources to complete your large order.

Board type

The type and size of your PCB will determine its costs. For instance, military-grade PCBs require more technologies and processes to complete. This is because of the type of board it is. Most times, high-frequency and high-performance boards require more cost to produce.

Digital parts availability

Your turnkey PCB manufacturer is responsible for all the stages of production. Also, this manufacturer is in charge of getting the raw materials needed for your PCB fabrication. Therefore, the availability of the parts influences the cost of turnkey PCBs. More available parts result in cheaper boards.

Manufacturer’s equipment

The equipment, facility, and technology of your manufacturer matter a lot. The best turnkey PCB manufacturers use state-of-the-art technologies and software. Also, this will contribute to the cost of your board.

Delivery fee

This is an important factor that determines the cost of your turnkey PCB. Also, the cost of shipment is always included in the cost of your PCB. If the shipment fee is high, it will increase the cost of your board.

————————————————————-

Request PCB Manufacturing & Assembly Quote, Pls Send PCB File to Sales@raypcb.com Now

————————————————————-

Steps in Turnkey PCB Assembly Process

There are various steps involved in the turnkey PCB assembly process. These steps include:

Confirming the order details

The turnkey PCB assembler ensures it checks the order details thoroughly. This helps to detect any inconsistencies. Also, the company will check other important documents like the Gerber files and BOM. Ensure these documents correspond well. Also, it will check descriptions like part spacing and footprint accuracy.

Ordering and receiving PCB and its parts

The manufacturer places an order for all the required materials for the PCB assembly. Also, it orders the materials and components in excess of the exact number needed. This is important as some damages can occur during the assembly process.

Inspection of ordered components and materials

It is very important your PCB manufacturer inspects the incoming components and materials. Also, the manufacturer must test these components to verify their quality. The quality control unit of a turnkey PCB company handles this process.

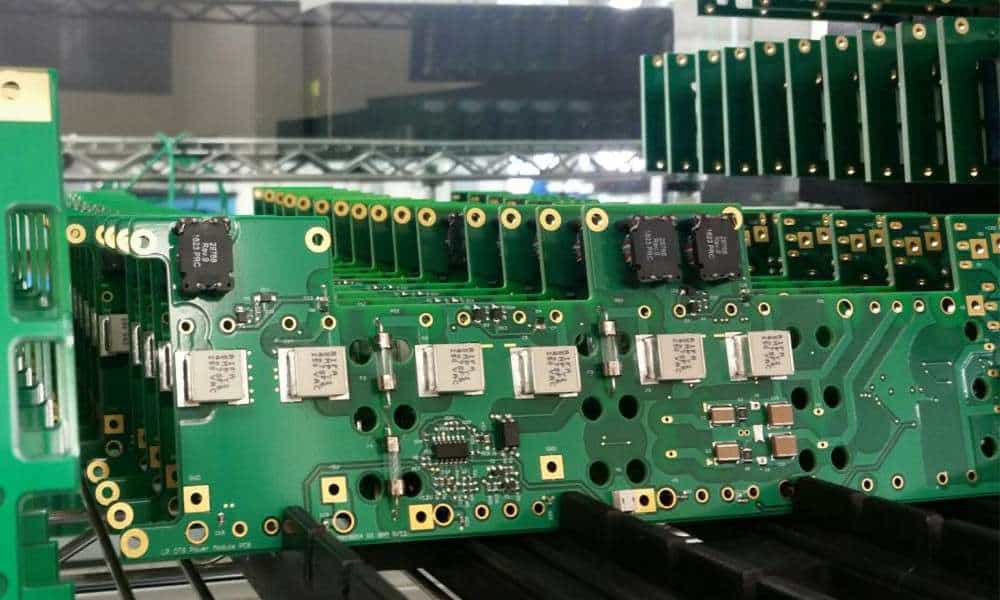

PCB fabrication

This is a long process. Now, your manufacturer has all the components and materials. It is time to fabricate your desired turnkey PCB. There are many steps involved in this process. These steps include solder pasting, solder masking, and more. Also, reflow soldering and component placement are steps involved in this process.

Final inspection

Inspection is a core aspect of turnkey PCB assembly. It checks for any defects or errors in the fully assembled board. Also, inspection ascertains the performance of a board. Automated optical inspection (AOI) and functional testing are good examples.

————————————————————-

Request PCB Manufacturing & Assembly Quote, Pls Send PCB File to Sales@raypcb.com Now

————————————————————-

Mounting Techniques Used in Turnkey PCB Assembly

There are different techniques used for mounting components on turnkey PCBs.

Surface mount assembly

This sophisticated technique uses a pick and place machine to place components on PCBs. Surface mount assembly is simpler and faster. This process uses automated machines to assemble components on a board. Also, this technique provides better production capacity.

Through-hole assembly

Through-hole assembly involves mounting through-hole components on a bare PCB. These components have leads that pass through already drilled holes. The leads will be well soldered on the other side of the PCB.

Mixed assembly

This involves the combination of SMT and THT. Also, this method allows the assembling of SMT and THT components in one board. Therefore, it incorporates the strength of THT and SMT. Mixed assembly gives room for more components as the components are on both sides of the board.

Conclusion

Turnkey PCBs are ideal for PCB users who want a ready-made PCB. These PCB users don’t want to be involved in the whole manufacturing process. Also, turnkey PCB assembly is a suitable option for young start-ups. This is because it eliminates the costs of shipping parts.

Comments are closed