Some of the best wireless radio antennas are the 2929 bondply and Rogers RT duroid 5780. What follows is a detailed analysis of the Rogers RT duroid 5880, covering both the phone and the service. The advantages of each will also be discussed. Okay, let’s jump right in! Is this the most effective antenna for a wireless radio? If so, would you recommend spending that much?

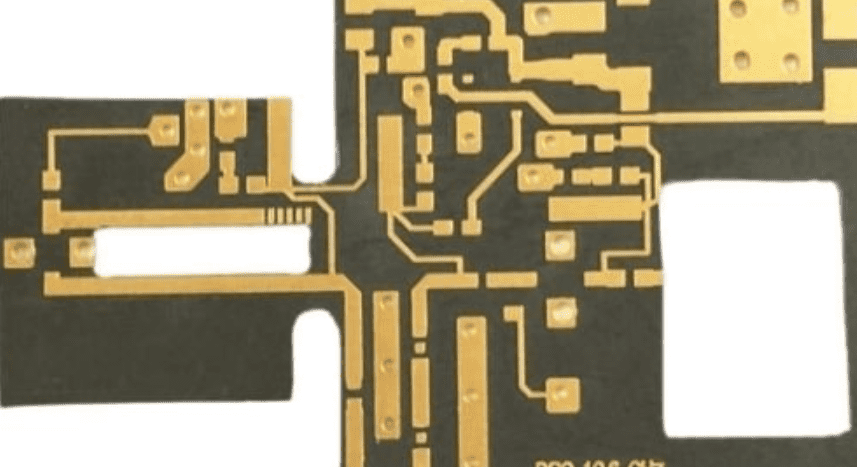

Rogers RT Duroid 5880

Here we will go over the positive and negative aspects of the Rogers RT-5880. The Rogers RT-5880 is widely used in electrical design. Because of its low dissipation and minimal loss. Aside from that, its dielectric constant is uniform throughout a wide range of frequencies. The cost is also fair at roughly $180.

RT/duroid 5880 is a composite made using a special filler. The used filler has a very low dielectric loss and dielectric constant. It’s ideal for use in both broadband and high-frequency applications because of this. Also, at only 1.4 g/cm3, the RT/duroid 5880’s compact construction is a notable feature.

Copper electroplating of thicknesses between 8 and 70um is feasible using the duroid/RT 5880. Its exterior is resistant to several solvents and chemicals. There’s also a lot of corrosion resistance and isotropy to go around as a result of its consistent electrical performance across a wide range of frequencies. Rayming Assembly & PCB incorporates it into their millimeter-wave designs. It’s great for a lot of uses because it doesn’t absorb a lot of moisture and has a low dielectric loss.

The antennas in this gadget are dual-band. The primary mode of operation for this high-performance Radio Frequency antenna is TM11 resonant. The dielectric permeability of the Rogers RT/Duroid 5880 is 0.086 mm, and its height is 0.508 mm. The RT/Duroid 5880 is a great option for both fixed and mobile communications. This is due to its highly modeled realized gain. The value of the gain is 1.7519 Watts.

Uses of Rogers RT duroid 5880

The Rogers Duroid/RT 5880 is a glass-microfiber-reinforced PTFE high-frequency composite. High-frequency and broadband applications benefit greatly from the material’s lower dielectric constant and very low thermal expansion coefficient. High temperatures and corrosion are no match for this material, either. Some of its most common applications are listed below.

It possesses low dielectric constant and minimal loss. In addition to this, it is mechanically and chemically stable. Ideal for use in complex stripline circuits. One of its main benefits is how little energy it wastes. There is a wide variety of forms and styles to choose from. The uses and advantages of various laminates vary depending on their specific composition. When it comes to military and space use, Rogers Duroid/RT 5880 is a top pick.

Although it is resistant to corrosion, the Duroid/RT 5880 laminate is simple to cut and shear. For through-hole procedures, this material is highly recommended due to its low dielectric loss. The laminate can withstand some water without being damaged. As an added bonus, the laminate’s electrical properties get preserved across a broad frequency range because it is isotropic. You can trust Rogers RT/Duroid 5880 composite to provide exactly what you’re looking for, whether that’s a high-quality smooth or an edgy, flat surface.

A low CTE is another crucial feature of the Rogers Duroid/RT 5880 PCB. It expands or contracts by less than 0.02 percent under heat or cold. For this reason, the Rogers Duroid/RT 5880 board can be exposed to significant amounts of moisture without suffering any deterioration in its performance. The low CTE of this PCB also makes it a good choice for use in HF applications, where stability is of the utmost importance.

Properties of Rogers RT duroid 5880

The characteristics of Rogers duroid/RT 5880 could spark your curiosity, especially if you’re looking for a new composite material. PTFE composite materials are widely used in the highly rigorous fields of communication, defense, and aerospace. When it comes to electrical conductivity, moisture resistance, and abrasion resistance, these laminates really shine. They also work well in high-frequency systems. For example, those found in telecommunications, microelectronics, mm-wave systems, and even missiles.

Rogers Duroid/RT 5880 laminates are suited for wide-band and high-frequency applications. This is due to their minimal moisture absorption and low dielectric loss. A small percentage of the surrounding humidity gets absorbed by the material. This makes it a good choice for damp settings. These features make Duroid/RT 5880 laminates a popular choice for microwave RF PCBs.

The Rogers Duroid/RT 5880 composite material has low emission and high-frequency properties. And is simple to cut to shape and size. The material’s high-frequency performance and resistance to corrosion from a wide range of chemicals have made it a favorite. High heat and corrosion are no match for laminates made from Rogers RT/Duroid 5880.

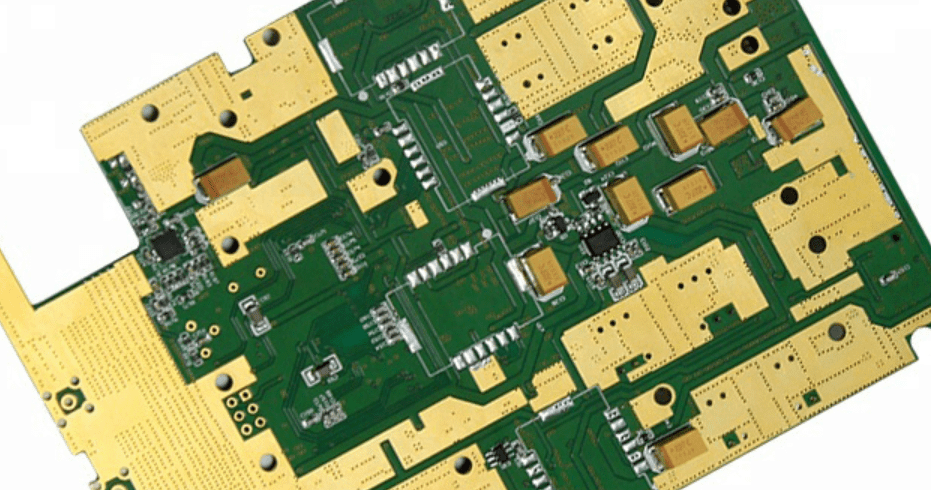

Rogers 2929 bondply

It is possible to use either thermoplastic or thermoset adhesive with the Rogers duroid RT 5880 multilayer circuit board. A combination of flame-retardant resin and fiberglass cloth make up the board’s material. This material configuration excels in RF and other HF applications. Because of its high conformal adhesion, minimal dissipation factor, and low dissipation coefficient. It is suitable for uses involving the bonding of circuits to one another.

The dielectric loss and dielectric constant (Dk) of duroid/RT 5880 laminate are both small. As a result of these characteristics, it is a great option for use in high-frequency and broadband settings. The laminate may be easily trimmed because of its low thermal expansion coefficient. Its dielectric constant is likewise quite small. It also means more payload capacity and reduced total expenditures. The laminate performs admirably in applications where it is critical. For example, in power converters, antennas, and electronic components.

RT/duroid 4000 and RT/duroid 5880 are two of the HF circuit materials you can make use of. These HF laminates are ideally suited for usage in complicated stripline circuits. In addition, this substance can be used in radio antennas, microstrip circuits, missile guidance, and military radar.

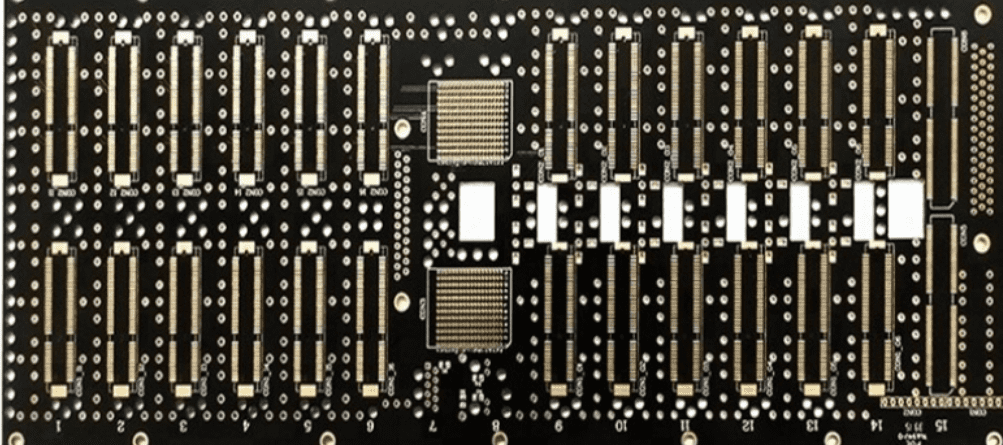

Laminate – Rogers RT duroid 5880

Rogers duroid/RT 5880 laminate, despite its name, is an HF composite composed of glass microfiber-supported PTFE. It is ideal for high-frequency uses because of its small dielectric constant and solvent resistance. This material is perfect for use in stripline and microstrip circuits. This is due to its high-frequency characteristics. It has a low carbon footprint, is strong and long-lasting, and is simple to manufacture.

Many different kinds of circuits can benefit from this Rogers duroid/RT 5880 laminate. It is perfect for use in high-strength stripline circuits. This is due to its lower density and dielectric constant. The laminate is purchasable in a variety of thicknesses and styles. You can pick between the regular version and a double-sided one. Both are quite easy to drill in. The glass microfiber reinforcements they use are of the highest grade as well.

This HF PCB is resistant to both high temperatures and corrosion. As such, it functions superbly in microstrip circuits and radio antennas. The laminate can also be used in high-frequency systems like missile guiding and military radar.

An excellent material for circuits is the duriod/RT 5880 laminate. Laminate may be disinfected using chemicals and requires little effort to clean. Metal plating is simple to apply as well. Due to its low dielectric constant, it is very corrosion and wear-resistant. This electronic component works well with others of its kind. However, the laminate’s high price tag can be a deterrent to its use in some contexts.

Composite – Rogers RT duroid 5880 PTFE

High dielectric constant homogeneity and lightweight construction of PTFE high-frequency composites reinforced with glass microfibers make them a great choice for use in defense and aerospace systems. The moisture absorption and dielectric loss of these materials are exceptionally low. They are also very temperature stable at mm-wave and mm-microwave frequencies. The electrical and mechanical qualities of Rogers duroid/RT 5880 PTFE laminates are superior. These qualities make them a good choice for high-frequency circuits and spacecraft payloads.

There is little difficulty in making circuit boards from either of Rogers’ RT/duroid 5880’s two available materials. On top of that, the former may be put together with less effort than the latter, which necessitates additional plating. However, the 5880 is the preferable option if you’re designing a circuit that needs extremely high electrical characteristics.

PTFE-filled laminates of ceramic RT/duroid 6010LM, duroid/RT 6010LZ, and RT/duroid 5880LZ all have permeabilities of 10.2, making them suitable for HF, lightweight, and ultra-high reliable applications. These materials are not only lightweight but also simple to manufacture and exhibit high levels of mechanical and thermal stability.

You can use common plating and soldering techniques on PTFE composites made from RT/duroid 5880. Its low dielectric constant and loss makes glass-microfiber-reinforced PTFE composite a good choice for shaping and bending in single-bend applications. Standard etching techniques and soldering masks are also suitable for the Rogers duroid/RT 5880 PTFE composite.

Why should one use Rogers 5880?

When it comes to cost, production capacity, electrical performance, and durability, FR-4 material is the gold standard of PCB substrates. However, if your design relies heavily on electrical features and cutting-edge performance, Rogers 5880 materials are where it’s at.

Is the PTFE reinforced with glass fiber Duroid / RT? 5880 HF laminate is a material with excellent electrical and mechanical properties at high frequencies. These microfibers are dispersed randomly throughout the material, increasing its strength significantly for use in and manufacture of electronic circuits.

These HF materials are ideal for wide-band and high-frequency applications that need minimal dispersion and loss because they have the minimum dielectric properties of the same sort. Moreover, Duroid / RT? 5880 is an excellent option for use in high-humidity settings because of its exceptionally low water-holding capacity.

Cutting Duroid / RT 5880 into the correct shape is simple, and it is corrosion-resistant against all reagents and solutions often used for plating and etching through holes. When it comes to electrical characteristics, Duroid / RT 5880 and 5870 laminates excel because they have a low dielectric loss, are moisture resistant, are isotropic, and show little frequency-dependent variation in electrical properties.

Benefits of Rogers 5880

- Uniformity in electrical characteristics over a broad range of frequencies

- readily available for cutting, sharing, and machining.

- Plating and etching holes and edges won’t dissolve or react with it.

- Suitable for use in damp places

- Reliable material

- The PTFE reinforcement with the lowest electrical loss

Considerations while using Rogers 5880

When making multilayer PCBs out of Rogers RT/duroid 5880 composites, there are a few things to keep in mind.

· Preparation of Inner Layers

Use the tried-and-true photoresist method and etch. Keep an as-etched dielectric surface as another priority. Because of this, surface treatment with salt is not required.

The proper treatment for a copper surface is determined by the adhesive system.

· Adhesive Systems

The Rogers RT/ duroid 5880 multilayered circuit board best adheres with thermoset or thermoplastic adhesive methods.

A thermoplastic method should be used whenever the electrical characteristics of the circuit board are crucial. When the electrical characteristics of your PCB are not crucial, you can utilize any thermoset technique.

· Processing the Bond of the Board

When handling the outer layer, you can follow the rules for double-sided processing circuits.

· Comparing Rogers 5880 with FR 4

The Rogers 5880 is a high-quality laminate that operates at extremely high frequencies. This is helpful for applications that require high frequencies, as opposed to FR-4, which performs best at significantly lower frequencies. The purpose of this article is to compare and contrast the information presented in FR-4 and Rogers 5880.

- The Dk of FR-4 is 4.5, while that of Rogers 5880 is only 2.2.

- To break down, Rogers 5880 and FR-4 require temperatures of 305 and 500 degrees Celsius, respectively.

- In contrast to FR-4, roger 5880 laminate maintains its consistent dielectric value of 5880 over a wide range of frequencies and between panels.

- As for electrical loss, Rogers 5880 is superior to FR-4.

- FR-4 material is more cost-effective than Rogers 5880.

- The UL 94 V-0 flame resistance rating is shared by rogers 5880 and FR-4.

- FR-4’s moisture absorption value may range from 0.15 to 0.25%.

Conclusion

We have conducted an extensive analysis of the Rogers 5880 and associated materials. The Rogers duroid RT 5880 excels in a wide variety of settings, including microstrip circuits, radio antennas, military radar, and missile guidance.

RayMing PCB has the capability to produce good quality Rogers 5880 using state-of-the-art techniques. You can rest assured that this will accommodate all of your PCB-related activities.

Comments are closed