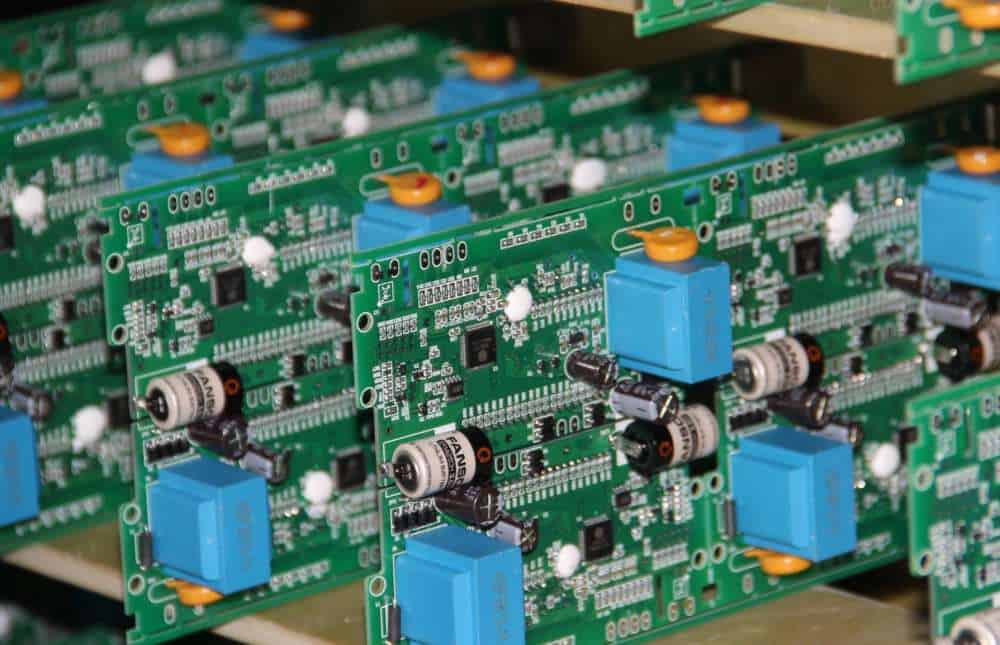

Surface mount technology (SMT) assembly is a popular method of assembling electronic circuits. It involves placing electronic components directly onto the surface of a printed circuit board (PCB), rather than inserting them through holes in the board. This method has become increasingly popular due to its many advantages over traditional through-hole assembly.

One of the main advantages of SMT assembly is that it allows for smaller and more compact circuit designs. This is because the components can be placed closer together and on both sides of the PCB. This also makes the circuit more reliable and less prone to failure. Additionally, SMT assembly is faster and more cost-effective than through-hole assembly, making it the preferred method for many manufacturers.

What is SMT Assembly Quote?

SMT Assembly Quote refers to the process of providing a quote for Surface Mount Technology (SMT) assembly services. SMT assembly is a method of electronic circuit assembly that involves placing surface-mount components onto a printed circuit board (PCB) and then soldering them in place. This process is used in the manufacturing of a wide range of electronic devices, including smartphones, computers, and other consumer electronics.

SMT assembly quotes are typically provided by contract manufacturers (CMs) who specialize in providing SMT assembly services to OEMs (Original Equipment Manufacturers). The quote will typically include a breakdown of the costs involved in the SMT assembly process, including the cost of materials, labor, and any additional fees or charges.

When requesting an SMT assembly quote, it is important to provide the CM with a detailed bill of materials (BOM) and Gerber files for the PCB design. This will allow the CM to accurately estimate the costs involved in the assembly process and provide an accurate quote.

In addition to the cost breakdown, SMT assembly quotes may also include information on the lead time for the assembly process, as well as any additional services that the CM may offer, such as testing, inspection, and packaging.

Overall, obtaining an SMT assembly quote is an important step in the manufacturing process for electronic devices. By working with a reputable CM and providing detailed information about the PCB design and BOM, OEMs can ensure that they receive an accurate quote and high-quality SMT assembly services.

Benefits of SMT Assembly Quote

Time-Saving

One of the primary benefits of SMT assembly quote is that it saves time. SMT assembly is a highly automated process that allows for the quick and efficient assembly of electronic components onto printed circuit boards (PCBs). With SMT assembly, the placement of components is done by machines, which reduces the need for manual labor. This results in faster turnaround times for PCB assembly, which is especially important for companies that need to get their products to market quickly.

Cost-Effective

Another benefit of SMT assembly quote is that it is cost-effective. SMT assembly is a highly efficient process that reduces the amount of waste and scrap that is generated during the assembly process. This results in lower costs for both materials and labor. Additionally, SMT assembly allows for the use of smaller components, which are often less expensive than larger components. This can help to reduce the overall cost of the PCB assembly process.

Accurate Pricing

Another benefit of SMT assembly quote is that it allows for accurate pricing. With SMT assembly, the placement of components is done by machines, which reduces the likelihood of errors and inconsistencies in the assembly process. This results in more accurate pricing for PCB assembly, which can help companies to better plan and budget for their production costs.

Overall, SMT assembly quote offers a number of benefits for companies that need to quickly and efficiently assemble electronic components onto PCBs. By saving time, reducing costs, and providing accurate pricing, SMT assembly can help companies to improve their bottom line and get their products to market faster.

Factors Affecting SMT Assembly Quote

When it comes to SMT assembly quotes, there are several factors that can affect the final cost. Here are some of the key factors to keep in mind:

PCB Design

The design of the printed circuit board (PCB) can have a significant impact on the cost of SMT assembly. Factors that can affect the cost include the size and complexity of the board, the number of layers, the type of materials used, and the placement of components. PCBs with smaller dimensions and fewer layers tend to be less expensive than larger, more complex boards.

Assembly Complexity

The complexity of the assembly process can also impact the cost of SMT assembly. Factors that can affect the complexity of the assembly process include the number of components, the type of components, and the placement of components. Assemblies with a large number of components or complex component placement may require more time and labor, which can drive up the cost of the assembly.

Component Availability

The availability of components can also impact the cost of SMT assembly. Components that are in high demand or difficult to source may be more expensive, which can drive up the cost of the assembly. Additionally, if certain components are not available, it may be necessary to substitute them with similar components, which can also impact the final cost of the assembly.

In summary, the cost of SMT assembly can be affected by a variety of factors, including PCB design, assembly complexity, and component availability. By understanding these factors, you can better estimate the cost of your SMT assembly project and make informed decisions about the design and components used in your assembly.

How to Get an SMT Assembly Quote

If you need an SMT assembly quote, there are two ways to get it: online quote request and manual quote request. Once you have the quotes, you can compare them to choose the best one for your needs.

Online Quote Request

The easiest and fastest way to get an SMT assembly quote is to use an online quote request form. Most SMT assembly companies have a form on their website where you can enter your project details and get an instant quote. The form usually asks for the following information:

- PCB specifications (size, layers, thickness, material)

- Bill of materials (BOM) with part numbers, quantities, and manufacturers

- Assembly specifications (SMT, through-hole, mixed)

- Quantity

- Lead time

- Additional requirements (testing, conformal coating, etc.)

Once you submit the form, you will get a quote within minutes. Some companies may offer a discount for online quote requests.

Manual Quote Request

If you have a complex project or special requirements that cannot be accommodated by an online quote request form, you can request a manual quote. This involves contacting the SMT assembly company directly and providing them with your project details. You can do this via email, phone, or online chat. The company will then create a custom quote for you based on your specifications.

To ensure that you get an accurate and timely quote, make sure you provide the following information:

- PCB specifications (size, layers, thickness, material)

- Bill of materials (BOM) with part numbers, quantities, and manufacturers

- Assembly specifications (SMT, through-hole, mixed)

- Quantity

- Lead time

- Additional requirements (testing, conformal coating, etc.)

Quote Comparison

Once you have received the quotes, you can compare them to choose the best one for your needs. When comparing quotes, consider the following factors:

- Price

- Lead time

- Quality

- Customer service

- Additional services (testing, conformal coating, etc.)

Make sure you read the fine print and ask any questions you may have before making a decision. Remember that the cheapest quote may not always be the best option. Choose a reliable and experienced SMT assembly company that can meet your requirements and deliver high-quality products.

Conclusion

In conclusion, obtaining a quote for SMT assembly can be a complex process that requires careful consideration of several factors. The cost of the components, the complexity of the assembly, and the volume of the order are all important factors to consider when requesting a quote.

One important thing to keep in mind is that the lowest quote may not always be the best option. It’s important to consider the reputation and experience of the assembly provider, as well as their ability to meet your specific needs and requirements.

When requesting a quote, be sure to provide as much detail as possible about your project, including the specific components and quantities required, any special requirements or considerations, and your desired timeline for completion.

By carefully considering all of these factors and working with a reputable and experienced SMT assembly provider, you can ensure that your project is completed on time, on budget, and to your exact specifications.

Comments are closed