You have many reasons to use the FR5 PCB materials in your next Printed Circuit Board (PCB) design. Indeed, there are many consumer needs as they relate to PCBs, and having one of the best materials is a good way to start.

We are pleased with what the FR5 PCB has to offer. That is why we have come up with this comprehensive guide to give you a heads-up on everything you need to know about this type of PCB material.

What Is FR5 PCB?

The FR5 substrate is made up of woven glass reinforced material and an epoxy resin binder. It is one of the most used materials for the design and manufacturing of circuit boards.

In terms of the specifications, there are many features that you will like about the FR5 PCB. The first is the maximum operating temperature of 140 degrees, which ensures that the circuit board doesn’t overheat or goes above the recommended temperature. The second attribute is the thermosetting fiberglass composite that is there to further enhance the resistance of the circuit board to a flame.

Worthy of mention is that the FR5 PCB isn’t the only type of PCB material out there. There are many of those, and these include the FR1, the FR2, and the FR4 PCB materials. That is not leaving out the FR4 PCB material, which is a fierce competitor to the FR5 PCB material.

The Competition between the FR4 and the FR5 PCB Materials

It is not out of place for a variant of the Printed Circuit Boards (PCBs) to provide better features than what the others would. That has been the basis of the competition between the FR5 PCB and the FR4 PCB materials.

Interestingly, the similarity between the two is impressive. They both have multiple use cases, including high-temperature applications.

However, the primary difference between the two lies in the heat resistance and the number of layers that each of the materials can be used.

Features of the FR5 PCB Material

For maximum comprehension of what you stand to benefit from using the FR5 PCB, we will like to highlight some of the features.

1. Moisture Absorption

There is no doubt that the removal of moisture, especially when it becomes excessive is one of the important elements to be considered when selecting a PCB material.

In the case of the FR5 PCB, the moisture absorption is low. To that end, it will make a good material to be used for your next circuit board.

2. Resistance

If a circuit board can resist many things, it implies that the chances of developing faults will be lower.

That inspires why the design of the FR5 PCB is impressive with the high chemical resistance. That is not leaving out the fact that it has a low dielectric loss.

3. Mechanical Properties

While checking the components of a PCB material, one of the important things to look at is the properties that are tenable in the mechanics of the circuit board.

Interestingly, the FR5 PCB has mechanical properties that are not only impressive but also enhance the functionalities of the circuit board where it is used.

4. Excellent Performance

There are many ways to evaluate the performance of a circuit board. That includes but is not limited to the mechanical properties and the entire composition of the board.

Therefore, investing in the FR5 PCB is the right thing to do considering the excellent performance. One of the ideal ways of confirming the performance of the FR5 PCB is by checking the performance during the lead-free soldering process.

Use Cases

Are you looking to see where the FR5 PCB will be deployed? Well, there are many use cases and applications where circuit boards designed with the FR5 PCB material can be deployed.

We will explain just a few so you will understand that the use cases and applications are not only many but are channeled in the right direction.

High-Temperature Applications

If there is anything that endears consumers to the FR5 PCB material, it is the excellence as far as high-temperature applications are concerned.

Already, the FR5 PCB material has many components that are in one way or the other, designed to reduce the heating on the circuit board.

PCB Testing

As awkward as this may sound, one of the major use cases and applications of the FR5 PCB is when it is time to test the circuit boards.

Sometimes, the PCB manufacturer may have made some mistakes in the process of designing and manufacturing the circuit board. In some other cases, the consumers may not be satisfied with the outcome of the design.

No matter the outcome of the design, the fact is that something could be done to forestall the negative outcomes. That is the essence of the PCB testing undertone to the FR5 PCB. With this, you can check and evaluate your circuit board before it is released

Serves as Insulation Structural Parts

The insulation properties in the FR5 PCB are many. And considering that the insulation of a circuit board is an important element for protecting the board from overheating, the insulation properties of the FR5 PCB will come in handy.

According to the PCB industry analytics, the components of the FR5 PCB can be used as insulation structural parts.

Also, the primary use cases or applications of these parts are in the electrical equipment and motor.

Automotive Industry

It is time you know that most of the Printed Circuit Boards (PCBs) used in automobiles are made from the FR5 PCB material.

One of the major reasons why PCB manufacturers, as well as the consumers, are pleased with the material is because of the improvements in the Tg, which is the Glass Transition Temperature.

Therefore, the higher glass transition temperature of the FR5 PCB pegged at 160 degrees, as well as the maximum operating temperature of 140 degrees goes the extra mile to improve the sturdiness of the components of automobiles where it will be used.

Aside from that, there are some other use cases of the FR5 PCB. That includes the use in the designing and manufacturing of circuit board holders, solid frames, antenna isolators, and test boards.

Why the FR5 PCB Is Better Than the FR4 PCB

You may be wondering why the FR4 PCB is competing with the FR5 PCB. The fact is that both have something unique to offer, as far as the designing of Printed Circuit Boards (PCBs) is concerned.

Aside from that, there are some advantages and reasons why the FR5 PCB is steadily topping the charts over the FR4 PCB.

Here are some of the better advantages that the FR5 PCB has, which help to set it apart from its fierce competitor – the FR4 PCB.

1. Smaller Z-CTE

The first advantage that the FR5 PCB has over the FR4 PCB material is the size of the Z-CTE.

Because of the smaller size, the FR5 PCB is undoubted, ideal for multiple use cases. That is why PCB manufacturers don’t find it difficult to use the same for high multilayer circuit board designs.

2. Higher Tg

The higher the Glass Transition Temperature (Tg), the more the use cases and applications of the PCB material.

Without any iota of doubt, the other reason why the FR5 PCB is better than the FR4 PCB is because of the higher Tg. It is because of the higher and improved Glass Transition Temperature (Tg) that the FR5 PCB is the best PCB material for the job.

3. Good Insulation Properties

The point is that if a circuit board doesn’t have good insulation, it tends to overheat.

Just as the Tg is improved, FR5 PCB also made plans to insulate the circuit board so that it wouldn’t be negatively affected by the outcome of overheating.

Besides, the good insulation properties of the FR5 PCB makes the difference, as it helps in keeping overheating at bay.

4. Better Heat Resistance

There is no gainsaying that the FR4 PCB has a good heat resistance that prevents the circuit board from overheating.

Yet, there are many other important factors to consider. That is where the FR5 PCB comes in with better heat resistance.

When checked, the heat resistance of the FR5 PCB is about twice of what it derivable on the FR4 PCB.

5. Moisture Resistance

It makes sense to keep moisture or water out of the circuit board. Even when you are watching, there is a likelihood that moisture may still find its way into the Printed Circuit Board (PCB).

In light of that, the moisture resistance of the FR5 PCB is a great consideration. Ideally, what is done here is to absorb moisture so that the filtration into the circuit board will be lower.

6. Electrical Strength

The other important consideration of the FR5 PCB is electrical strength. Because every component is important and the electrical is highly valued, it makes sense that the strength of the same should be solidified.

The input of the FR5 PCB in this regard may not be fully explained. However, the takeaway is that the use of the FR5 PCB material in a circuit board goes the extra mile to provide good electrical properties to the circuit board.

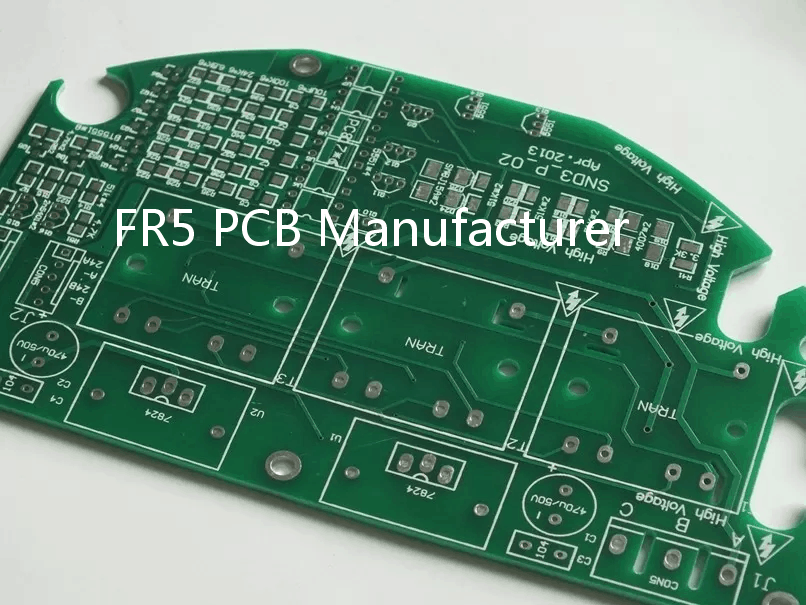

FR5 PCB Designs

There is no end to what can be made out of the FR5 PCB. The PCB manufacturer is expected to have an eye for details, as well as understand the procedures so that it can have a swell time when designing the FR5 PCB.

Of course, there are different PCB designs that can be made out of the FR5 PCB. Below are some of them:

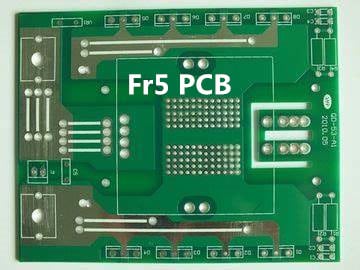

Double-Sided PCB

If you are looking at designing a Printed Circuit Board (PCB) that has two sides, it is pertinent that you consider the Double-Sided PCB designed under the auspices of the FR5 PCB material.

Rigid

The rigid PCB can be also designed with the FR5 PCB as the base material. The expertise of the manufacturer and the availability of the needed materials will determine the success of the job.

Multilayer

On the other hand, there is an opportunity for you if what you are considering is a PCB that has more than two sides.

In that case, the multilayer property of the FR5 PCB is what you will need to design a circuit board that has multiple layers.

How to Select the Best FR5 PCB Manufacturer

It is one thing to understand and cherish all that the FR5 PCB has to offer. It is another thing to make it reality by selecting the best PCB manufacturer for the job.

If you are at a crossroads or you don’t know what to have in mind when considering a manufacturer, we are here to help you.

Here are some of the factors that will help you get the best PCB manufacturer that will help you hire the best FR5 PCB manufacturer:

1. Location

You want to confirm that the PCB manufacturer is close to you. The proximity of the manufacturer matters a lot because it helps you to always walk in or be in constant communication with the PCB manufacturer to ascertain the status of your design.

2. Material Sourcing

This can be the source of problems between the PCB manufacturer and the consumers if it wasn’t talked about at the onset.

So, you have to determine if the PCB manufacturer is willing to source for the materials for the circuit board.

It is important that the FR5 PCB manufacturer does the sourcing because of the expertise and the immediate access to the materials upon payment.

3. Cost

No doubt, an excellent PCB material like the FR5 PCB tends to attract more costs. Therefore, ensure that you did some market research and background checks to confirm if the quoted cost of the circuit board you want to design fits into your budget.

Final Words

The FR5 PCB has some of the best components as far as Printed Circuit Board (PCB) designs are concerned.

We are hopeful that you will like the outcome of your circuit board after it must have received the “FR5 PCB touch.”

Comments are closed