Different kinds of Printed Circuit Boards (PCBs) exist, but the Polyimide PCB has been getting the attention lately. This article highlights the top five (5) manufacturers of this type of PCB.

What is the Polyimide PCB?

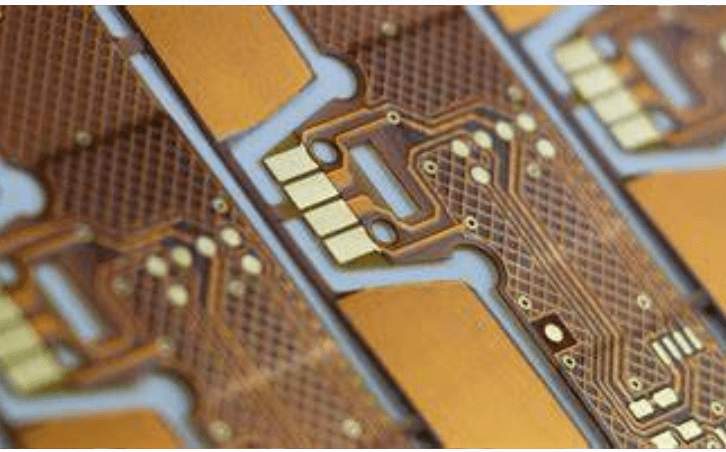

It is a type of circuit board made with Polyimide, which is a flexible material used for the production of circuit boards. According to Hillaman Curtis, the Polyimide used in the circuit board is also a set of “polymers that have imide monomers.”

The general submission is that the Polyimide PCB is a type of circuit board that is used in applications that require utmost flexibility.

Who Manufactures the Best Polyimide PCB?

When it comes to the production of the Polyimide PCB, one of the core focal points is the reliability of the manufacturer. With many PCB companies out there, narrowing down to a choice can sometimes be difficult.

However, it is possible to pick the best Polyimide PCB to work with when you consider some of the important points.

Below, we have made a list of some of the leading companies that engage in the services of offering the best Polyimide PCBs.

1. PCBMay

If you are looking for a Polyimide PCB manufacturer in China, one of the companies to reach out to is PCBMay. It is one of the leading manufacturers of this type of PCB and it has an extensive year of experience in that field.

There are a couple of reasons why PCBMay is a reliable Polyimide PCB manufacturer and the following are some of those reasons:

Polyimide PCB Customization

Due to the technicalities, it is imperative to customize the Polyimide PCB to fit into the target applications. It is on this basis that PCBMay created a viable solution for consumers looking to optimize the board as per the targeted applications.

The customization of the Polyimide PCB is based on the file provided by the consumers.

Dual Service Delivery

While some Polyimide PCB companies focus on the manufacturing of the boards, others focus on supplying the boards.

However, PCBMay offers both the manufacturing and supplying of the Printed Circuit Boards (PCBs).

Innovative Solutions

You can rely on PCBMay to deliver the best Polyimide PCB services, in the sense that the company offers specialized manufacturing solutions for this type of PCB.

It is also imperative to point out here that the company also specializes in the optimization of the boards to fit into the type of target applications. This is in addition to the company’s commitment to offering round-the-clock solutions through the spirited efforts of the professional team of engineers.

PCBMay Manufactures Multiple Polyimide PCBs

You can also rely on PCBMay to manufacture and supply different kinds of Polyimide PCBs. On the list of the supported boards are:

- 14 layers of rigid Polyimide PCB

- 8 layers of rigid Polyimide PCB

- Double-sided Polyimide high temperature PCB

- 2 layers of rigid Polyimide PCB

- Polyimide flexible PCB

- Polyimide Stiffener Immersion Gold Circuit Board Rigid Flex PCB

- Multilayer Polyimide PCB

- 12 layers of rigid Polyimide PCB with heatsink

- Polyimide flexible surface mount PCB

- Custom Polyimide PCB

- OEM Polyimide PCB

- 3MIL Polyimide PCB 4Layer

- Single-sided Polyimide PCB

- 0.4MM Polyimide PCB

2. Rayming Technology

RayPCB is at the forefront of manufacturing the Polyimide PCB. The company is one of the leading manufacturers of Polyimide PCB and has over the years, perfected the art of making this type of circuit board.

Worthy of mentioning here is that the company also engages in the service of offering different kinds of Polyimide PCB production. Notable among these is the Arlon 84HP PCB, which offers the best performance, in terms of Polyimide PCB.

Specialized Polyimide PCB Production

RayPCB also manufactures different types of Polyimide PCBs. The types range from the Filled Polyimide PCB, Pure Polyimide PCB, Low-Flow Polyimides and the 3rd-generation Polyimide PCBs.

3. Imagineering Inc.

If you are looking for the best Polyimide PCB company to work with, consider working with Imagineering Inc. It is one of the manufacturers of this type of PCB that does not only offer real-time Polyimide PCB services, but also does so at affordable costs.

Here are some of the reasons why Imagineering should work on your next Polyimide PCB:

Commitment to the Project

Regardless of the type of Polyimide PCB you want manufactured or the additional specifics, you can count on Imagineering Inc. to make a great job of it.

The company’s commitment to the quality of the Polyimide PCB is derived from the dedication to ensuring that the circuit boards meet the AS9100D Certification.

Standardized Polyimide PCB Production

Imagineering Inc. also specializes in the production of Polyimide PCBs that align with the existing set of standards under the IPC-6011 standard, set by the IPC.

These standards cut across Class 1 and Class 3. While the Class 1 Polyimide PCB focuses on the general electronic products, that of Class 2 deals with the service electronics. The Class 3 Polyimide PCBs are for use with the harsh operating environment electronic products.

You can count on Imagineering to “provide the best Class 2 and Class 3 Printed Circuit Board fabrication.” It is also important to point out that the manufacturer prioritizes the delivery of the “best-in-class results on time, every time.”

4. Candor Circuit Boards

There are not many companies that specialize in Polyimide PCB but the few that offer the service excel at it. Candor Circuit Boards readily come to the mind because of the company’s versatile approach to Polyimide PCB production.

Here are some of the upsides to allowing this company handle your Polyimide PCB design needs:

Polyimide PCB Analysis

Candor helps analyze the needs of your Polyimide PCB, as they relate to the target applications. From this, the company hopes to manufacture the circuit boards that fit into the desired applications.

Additional Inputs

Candor also offers additional input and guidance where necessary to help you get the kind of Polyimide PCB that matches your desired needs and applications.

Multi-PCB Design

In addition to helping, you with “design work,” Candor also provides different kinds of Polyimide PCB designs. These designs range from:

- Filled Polyimides

- Pure Polyimides

- Low-Flow Polyimides and;

- 3rd Generation Polyimides

5. XPCB Limited

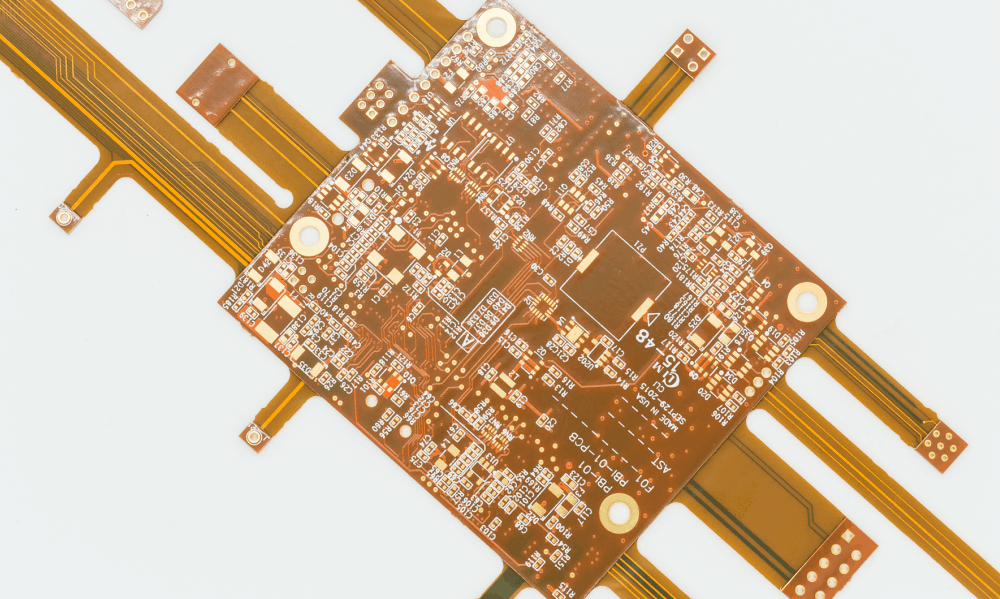

This is a “premium PCB & PCBA Manufacturer based in China.” XPCB specializes in the production of different Printed Circuit Boards (PCBs), as well as offering an array of Printed Circuit Board Assembly (PCBA) services.

In terms of Polyimide PCB, the company specializes in the integration of flexible circuit board solutions into the Polyimide PCB. This leads to the production of what it calls the “Long Flex PCB.”

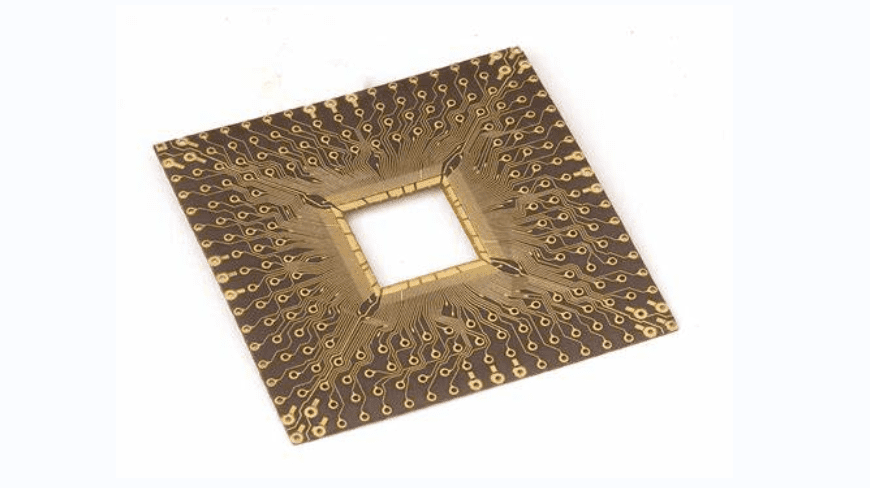

What is the Long Flex PCB?

It is a type of Printed Circuit Board (PCB) made out of polyimide material with ENIG. The circuit board measures 1100mm in length and is made of DuPoint Polyimide with ENIG finish.

Below are some of the additional properties of XPCB Limited’s Long Flex PCB:

- Built for High-Performance: the Long Flex PCB is “built for high 220˚C working temperature.” Thus, it is ideal for delivering the superior heat-resistance performance that matches the Polyimide Flexible PCB.

- Faster Production: The Long Flex PCB can be manufactured in 7 days or less, making it a quick-turn circuit board.

- Additional Specifications: the circuit board also has other specifications, including 5/5mil Min tarce/space and 0.28mm thickness.

What You Need to Know about the Polyimide PCB

Certain factors differentiate the Polyimide PCB from the other types of PCBs. Here are some of the things you need to know about it.

Polyimide PCB vs. FR4: Which is Better?

There is an ongoing debate on which is better between the Polyimide PCB and the FR4. Worthy of mentioning is that the Polyimide PCB breaks through the conventional use of the Flame Retardant Level 4 (FR4) type of PCB material because of the additional characteristics.

The FR4 is commonly known for the zero-water absorption, which makes it ideal for use with the standard applications. However, the FR4 material cannot be used with the applications that have been manufactured.

It is therefore, on that basis, that the Polyimide PCB proves a worthy replacement, owing to the “universality” that allows for the use with the flexible PCBs and the rigid-flex PCBs.

The flexibility of the Polyimide PCB that makes it ideal for use with the flexible PCBs can be attributed to the “stiffness” attributed to the FR4 Materials used for PCB design. For the PCBs relying on the FR4, they don’t always end up being flexible because the material gets stiff due to the combination of the copper lamination and the epoxy glass glue used on it.

However, the FR4 material proves to be a cost-saving variant to the Polyimide PCB, in the sense that it saves the consumers a considerable amount of money. The cost-saving design is derived from the Polyimide PCB’s extensive use, which makes it expensive.

Choosing a Polyimide PCB Manufacturer

The selection of the best Polyimide PCB manufacturer has to do with a lot of background checks on the prospective manufacturer’s integrity. Even at that, you don’t want to ignore the following factors:

Customized Solutions

One of the things to look out for is the Polyimide PCB manufacturer’s readiness to offer tailored solutions. The customized Polyimide PCB solutions should align with the customers’ needs and the industry’s requirements.

Can the Manufacturer Make Polyimide PCB Variations?

Is it possible for the manufacturer to move beyond offering customized Polyimide PCBs to making different variants of the circuit board?

While the Polyimide PCBs are a popular choice for use in making flexible PCBS, they can also be made into other forms.

The Polyimide PCB manufacturer you choose to work with should be able to make different kinds of Polyimide PCBs, such as:

- Third generation polyimides

- Pure polyimides

- Filled polyimides and;

- Low-Flow Polyimides

Why Choose Polyimide PCB?

If you are looking for reasons to choose the Polyimide PCB, there are several of them. In addition to making PCBs flexible (bendable and foldable), the Polyimide PCB can also be picked for the following reasons:

Polyimide PCB is Flexible

This is the Unique Selling Point (USP) of the Polyimide PCB. The flexibility allows for the consumer electronics and other targeted applications to conform to different uses and folding options.

The flexibility also makes the Polyimide PCB ideal for use in the applications that require more of portability and frequency.

Besides, you can rely on it to improve the longevity of consumer electronics, considering that the circuit board helps these electronics to “absorb impacts.”

Polyimide PCB is Thermally Stable

The stability of the Polyimide PCB interfaces with the flexibility and the capability to withstand heat. This is evident in the compressive strength and elasticity of the circuit board; a feature that makes it impossible for the board to cower under excessive temperature.

Besides, the Polyimide PCB can function in environments that have up to 300-degree Celsius of temperature. In addition, it can significantly help in reducing the damages associated with excessive temperature, as “polyimides don’t change temperature quickly.”

Excellent Chemical-Resistance

It is one thing for the Polyimide PCB to be resistant to excessive temperature and another not to get damaged by chemicals.

On the contrary, it has an excellent chemical-resistance, which is derived from the chemical stability of the polyimides. It allows for the circuit board to have limited corrosion, as a result of overt exposure to “hostile chemicals.”

Tensile Strength is Tenable

Polyimide PCB’s elasticity allows for the board to withstand conditions, relating to extreme stress and excessive temperature.

However, one other aspect that boosts the operation is the tensile strength, which has to do with the Polyimide PCB’s capability to suit the different applications.

For example, the tensile strength allows for the Polyimide PCB to support higher maximum loads, as well as being reformed to “suit the available area.”

Wrapping Up

Some of the reasons to choose the Polyimide PCB include the improved durability, the tensile strength, the chemical-resistance and the flexibility. RayPCB helps you customize this circuit board to fit into the different applications, ranging from medical electronics, automotive electronics and a host of other consumer electronics, such as computer electronics.

Comments are closed