The electronic contract assembly is a collection of services for designing circuits, fabrication of PCBs, assembly of electronic components on the PCBs, subsystem assembly of modular equipment, box build assembly, inspection and testing, packaging, and delivery Manufacturing of contract assemblies can be used either as a complement to or as a substitute for in-house manufacturing capabilities.

It is economical to get your electronic products manufactured by electronic assembly contractors. The perfect electronic assembly contract will prove to be an enormous advantage for your business. It is better to build a business partnership with contract assembly providers that offer economical services with quality product assembly. It is advisable to ensure that the cost-effectiveness of the assembly does not affect the reliability of the production; otherwise, the devices may end up falling short of the expectations. To prevent these issues, it is better to contract with a business that strictly follows manufacturing and assembly standards and uses high-quality electronic components in the assembly. The following kinds of manufacturers will provide more competent services and better-quality products at significantly less turnaround time.

————————————————————-

Request Electronic Contract Manufacturing Quote, Pls Send PCB File to Sales@raypcb.com Now

————————————————————-

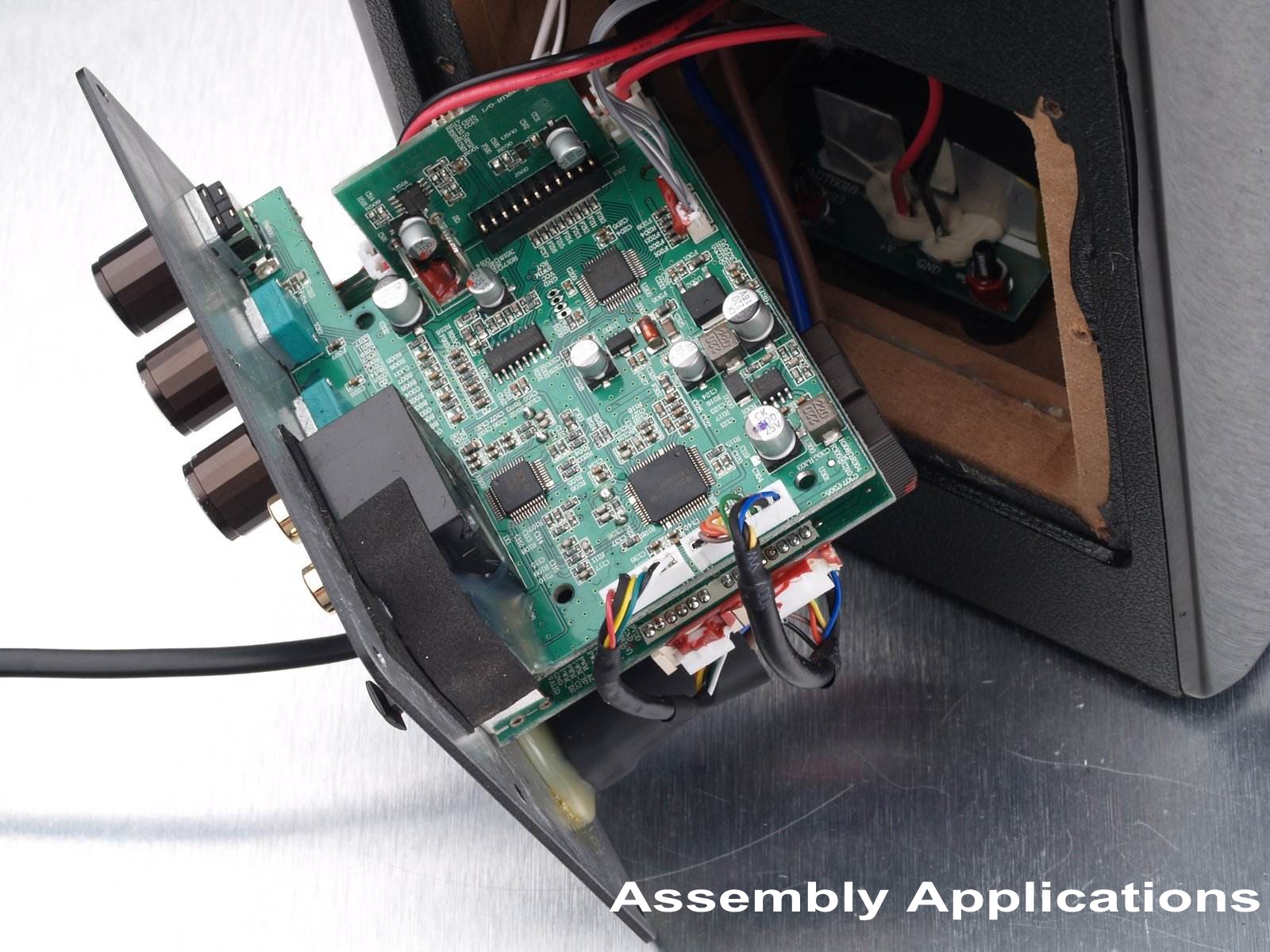

PCB Assembly

Electronic assembling technology is constantly evolving, and the size of PCB is reducing. Today, customers seek electronic products that are both highly lightweight and portable, albeit more complicated and practical. PCBs must get smaller in order for these devices to perform correctly and effectively, thus being able to accommodate even more complex electrical contacts and miniature parts. Designing and installing these small PCBs can be difficult, time-consuming, and quite expensive for electronics assembly manufacturers. You will want to contract with experienced electronic assembly manufacturers for you to satisfy client requests, remain competitive, and expand your business. Professional and competent contract partners will help you navigate the challenges in the outsourcing of electronic assembly. The supplier will use high-tech equipment to enable quicker, more reliable assembly of PCBs.

Systems Assembly

Electronic assembly contractors can assist businesses in dealing with systems assembly. By selecting an established contract assembly manufacturer that is acquainted with all the requirements of device assembly, you can receive tailored strategies that can better handle your business’s supply chain needs. Irrespective of the complexity of your requirements, an appropriate contract assembly supplier will provide greater satisfaction and better performance. Other benefits of partnering up with contract assemblers include design optimizations, manufacturing and assembly according to specifications, box build assembly at various levels, customized routing and cabling, inspection and testing, and the proper documentation to assist you in operating the device properly.

Design and Build Assembly

There are suppliers of electronic assembly contracts that only provide assembly facilities. Although this will allow you to increase the pace at which a fully engineered device is eventually made, it cannot help you improve the assembled equipment’s performance. In design-conscious electronics assembly, the manufacturer may suggest improvements in the circuit and PCB design, making the end product compact and efficient. These design considerations can reduce the cost of components and make the final product functional and more comfortable to operate. In the process of assembly, the contract supplier can identify the potential flaws and try to fix them before the assembly. Furthermore, a wide range of tests will be performed to check the assembled electronics’ functionality, offering design evolution opportunities over time.

————————————————————-

Request Electronic Contract Manufacturing Quote, Pls Send PCB File to Sales@raypcb.com Now

————————————————————-

Electronic Contract Assembly Applications

Hiring a company to facilitate for contract assembly production offers several benefits. Electronic Contract assembly Production has traditionally been able to reduce supply chain costs significantly, slashing them in half in certain instances. Electronic Contract assembly has, in some situations, allowed enterprises to function without requiring on-site assembly facilities. It enabled companies to focus on designing better products by providing more resources for specialized tasks. Many businesses can opt to outsource their well-established long-standing products to a contract manufacturer, allowing for a greater emphasis on internal operations for higher complexity new products that may have higher margins. Other significant advantages of outsourcing are manufacturing flexibility and access to more specialized outside expertise.

The contract assembly is popular among the sellers of high-volume devices such as mobile phones, hardware for telecommunications, laptops, vehicles, and a range of other consumer electronics. In terms of cost-effectiveness, suppliers of instrumentation goods, medical equipment, LED lighting devices, and fiber optic components are gradually considering contract assembly. A contract assembler may offer a range of services suitable for different applications. These services can include designing products, creating and testing prototype, high volume production, worldwide supply chain, after-sales support, and repair services.

Performance reliability and following standard manufacturing practices are enormously central in the assembling of products, especially in the process of mass manufacturing. Contract assembling facilities guarantee that the product’s quality is high and performance is consistent; this sophistication level is only possible with advanced equipment and trained operators. The dedicated facilities ensure that the electronic assembly components are procured from trustworthy sources, and the components are installed on the board correctly. The importance of contract assembly increases exponentially for the production of high-reliability devices such as medical and defense equipment. The devices cannot afford failure when they are operational.

Why choose Contract Assembly

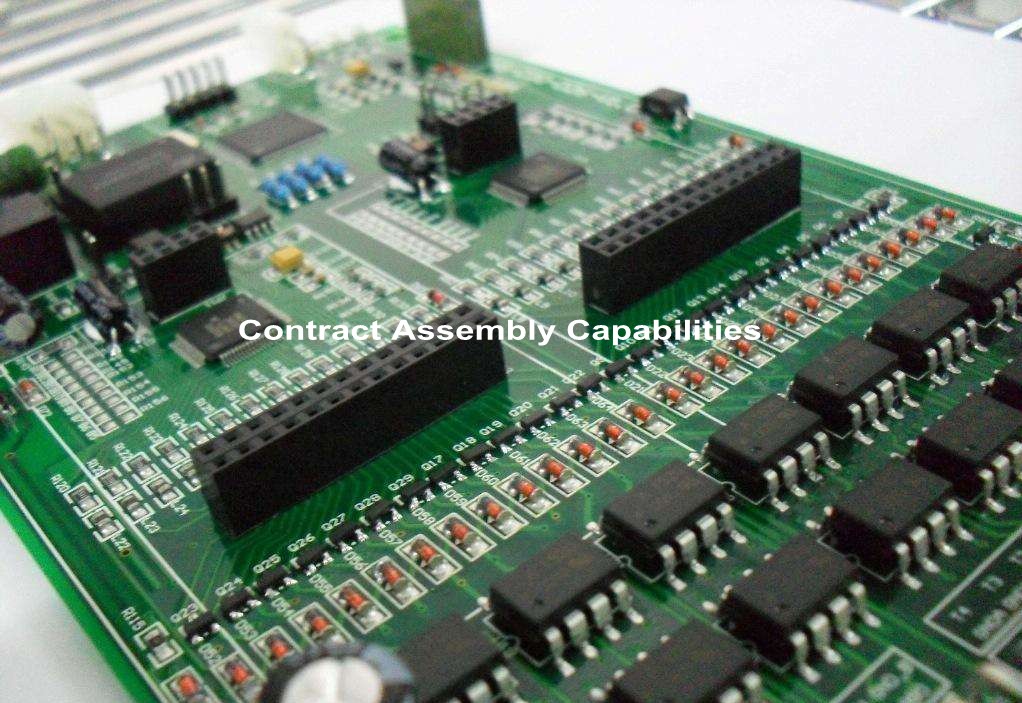

Generally, the contract electronic assembly providers have years of experience in the business of highly complicated assemblies. They follow stringent production standards, promising higher quality products. They have state of the art PCB fabrication and component placement machines. The tiniest of the components can be assembled with very high density and accuracy. An electronic assembly service involves the manufacturing and production of PCBs and the placement of various electronic components. There are various techniques for making PCBs; each technique has its advantages and disadvantages. A contract assembly supplier can better decide which method of production is suitable for a specific application. The most commonly used PCB fabrication methods are employ either surface mount technology (SMT) or plated through-hole (PTH).

In the SMT assembly process, the components are attached directly to the surface of the PCB with the help of the solder paste. SM assembly enables the incorporation of the small-sized components allowing the board size to decrease and assembly density to increase. Alternatively, TH assembly is an older technique; this technique is still applicable because some components are not available in SMT form. In TH assembly, the components are inserted into the holes drilled on the board; the insertion occurs with the help of the metallic wires extending from the component package. Through-hole assembly is only used when the surface-mount assembly may be either unfeasible or inaccessible.

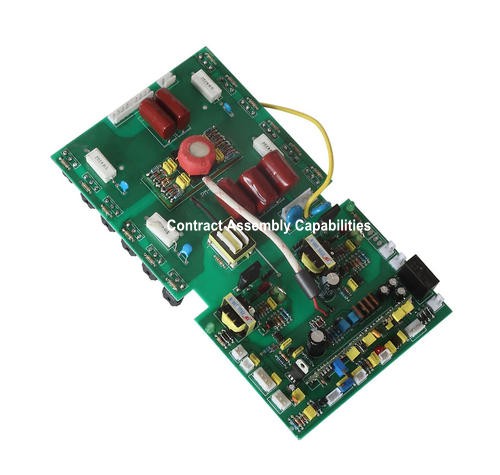

Contract Assembly Capabilities

Contract Manufacturing produces good quality electronic assemblies and devices. The ISO standards-accredited vendors are usually trustworthy, delivering PCBs on UL-approved laminates. In order to ensure conformity with the new requirements, these manufacturers hire IPC-certified specialists. The decision to pick an electronic contract assembler must be taken by carefully accessing the capability of the assembler to produce complicated high-density assemblies, package the assembly in a wide range of box builds, procure raw material in a transparent process, test the product sufficiently, manage multiple dedicated production lines, and RoHS compliance.

Additional facilities provided by a contract assembly supplier may include: Autonomous pick-and-place machines for surface-mount devices; support for micro-ball-grid-array (μBGA), the dual in-line package (DIP), and other SMT footprints; testing and verification of footprints; multi-zone compressed air convection reflow soldering; support for lead-free soldering; wave soldering; automatic optical inspection (AOI) after reflow, the capability to assemble through-hole components manually; Repairing of the SMT devices; ultrasonic cleansing of residuals; and box build assembly of final packages.

————————————————————-

Request Electronic Contract Manufacturing Quote, Pls Send PCB File to Sales@raypcb.com Now

————————————————————-

Bidding for Contract

If the bid-offer is for the procurement of a particular object or a device, most firms have basic requirements that must be met while bidding. The contract assembler needs to meet such requirements. Furthermore, any offer made as an official government deal would have to obey many rules and guidelines that the business’s contracting department needs to deal with. Bidding requirements have to be published. Suppose they are written on a particular component, product, tool, or system. In that case, the writer will have difficulty explaining another unit that may offer better performance but may not follow the desired requirements. One approach used is to compose bidding requirements so that any established contract assembly supplier will not fulfill all of them. This avoids claims that the writer has a specific vendor in mind and, if that seems necessary, causes all offers to be tossed out. It also permits any appropriate unit to be justified. This approach would result in a series of bid criteria on which each object is in the company’s best interests. The writer leaves some sign of conflict of interest or favoritism vulnerable to reprimand, lawsuits, or firing.

Efficient Delivery

Selecting a single contract manufacturing company can extensively analyze the design, preventing you from negotiating, and coordinating with multiple people at different facilities. Efficiencies in going from one stage to another to have a competitive deal may be taken advantage of by one single provider delivering the entire spectrum of services. The whole structure is carefully tested by an electronics contract assembly provider who can decide the right packaging and shipping options for your project. The packaging is an essential part of the method of assembly, but low importance is either ignored or provided.

It is necessary to obtain the correct packaging materials for safe shipping, particularly if the assembly has to be shipped to other countries. You will save money and prevent headaches with a contract assembly production provider comfortable with the international method and mindful of the delivery logistics. There may be possible downtime for several hands in your building as we wait for sections or other project phases to be finished. You will guarantee that your project is delivered in the most productive way possible by performing your project with a single electronic contract assembly provider, saving you time and cash in delivery and manufacturing delays.

The benefits of Contract Assembly

It is possible to outline the advantages for original electronics manufacturers (OEMs) by hiring contractors such as electronic manufacturing service (EMS) suppliers. Contract work enables them to: decrease development time-to-market and time-to-volume for their products; lower overhead costs, decrease capital spending and other fixed costs; enhance inventory control; access world-class processing, engineering, and distribution capacities; export the same commodity worldwide through the use of complementary manufacturing facilities; and focus on core manufacturing capabilities.

The contract assembly manufacturers provide custom enclosure fabrication services at state-of-the-art fabrication facilities. Other services offered by these facilities include designing, building, testing, and installing subassemblies. Additionally, the contract manufacturers may provide cable routing and wiring installation along with assembling all kinds of components. Some assemblies require the placement of customized components; a contract assembly manufacturer is typically able to provide modified component packages that can fit on a specific PCB. The assembly contractors uphold outstanding quality levels to provide practical, top-quality equipment for all consumer orders. The firm executes an exhaustive sequence of in-process testing and evaluation to mitigate the likelihood of final assembly errors on any project.

Electronic Design Assembly

Examples of criteria to be defined for an assembly contract are the efficiency, stability, durability, noise, and precision of the device. When working with computer-driven devices, access and processing speeds are fundamental parameters. It is the contract assembly manufacturer’s responsibility to select equipment that follows the specifications closely. The designers then develop a description of the equipment specifications for the assembly. The next stage in assembling electronics is the comprehensive design stage. The design phase is the part where the equipment is installed and tested for performance and reliability. The producer guarantees that all the functions are operational and the expenditure is fulfilled.

A flow diagram is a graphical sketch used to demonstrate the interconnections of all elements of the assembly. It is more complicated than the illustration of the block showing all the wiring and cabling. Flow diagrams must show the interconnection of every component to the additional subsystems. The contract assembler also provides cabling and connections plan configurations. All necessary documentation from suppliers is recorded. The assembly supplier assists the client in laying out requirements clearly and precisely.

Comments are closed