SWIMBI ELECTRONICS CONTRACT MANUFACTURING

Leading Contract Manufacturer providing solutions to the Electronics Industry.

We work hand-in-hand with our customers to develop and implement complete manufacturing solutions that meet your business challenges.

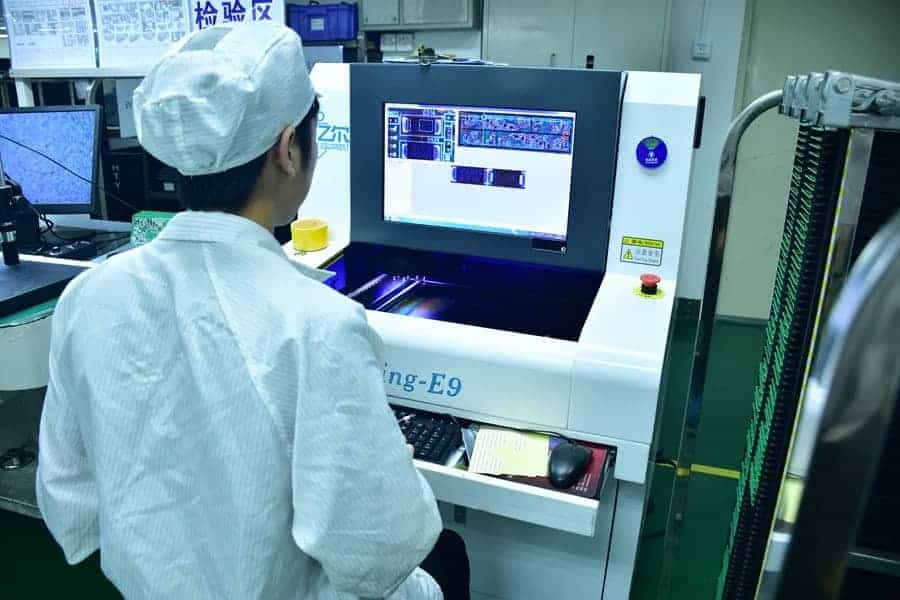

Our responsive processes and state-of-the-art facilities enable us to build your proprietary and cutting-edge products. We take them from prototyping through to full production manufacturing, quickly and to the highest quality standards.

Inspiring trust, MX Electronics Manufacturing is the contract manufacturing partner of choice.

INSPIRING TRUST THROUGH:

- Highly flexible and controlled processes

- Prototyping, NPI, Volume Production

- Rapid prototyping and quick turn manufacturing services

- 18 years of assembly expertise

- Specialized North American manufacturing facilities

- Engineering services

- Latest technology and equipment

- Lean manufacturing

What is Electronics Manufacturing Services (EMS)?

The term “electronics manufacturing services” (EMS) refers to an overall industry and also to a specific class of subcontractor or company. EMS is also often used interchangeably with the more generic term “contract manufacturing (CM)”. In short, EMS companies provide a wide range of value-added engineering and manufacturing outsourcing services to original equipment manufacturers (OEMs), allowing them to improve operational efficiencies and focus on core activities like research and development (R&D).

The electronics manufacturing services (EMS) market is dynamic, and the demand for electronic components and outsourced manufacturing services is growing.

The industry is forecast to grow at a compound annual growth rate of 7.5% between 2018 and 2024, according to market research.

Growing demand for consumer electronics and innovative technological advancements allows manufacturers to capitalise on current opportunities. With rising customer demands and the need to control costs, manufacturers may need to partner with solution providers that offer industry expertise and experience.

As a global leader in high-mix low-volume manufacturing, we see first-hand the evolution the EMS industry is experiencing and the critical role we play in the electronics value chain. In this new guide, you’ll learn about the driving factors of EMS, applications, challenges, and what to consider when outsourcing the manufacturing of your product.

Let’s dive in…

Chapters

- Electronics Manufacturing Services

- Comparing an OEM to an EMS Provider

- Outsourcing Electronics Manufacturing

- The Dark Side of Electronics Manufacturing

- What is High-Mix Low-Volume Manufacturing?

- [Future] Electronics Manufacturing Trends

Chapter 1

Electronics Manufacturing Services Overview and Applications

The core of any electronics manufacturing service offering stems from design, manufacture, test and distribution. An EMS provider will perform these functions which may also include full systems assembly for original equipment manufacturers.

For example, offering systems integration or “box build” services – manufacturers can use a process to combine printed circuit board assemblies, wire harnesses, fabrication of enclosures, testing and more.

The electronics manufacturing industry is broad and spans across government (aerospace & defence), consumer (smartphones, PC, etc.) and industrial products (robotics and automation), electronic components (connectors, semiconductors etc.), and health care (medical devices). As the EMS market continues to grow, four driving forces can be observed.

Electronics Manufacturing Industry Market Overview

According to Market Research engine, the major driving factors of the Electronics Manufacturing Services (EMS) market are:

- Rising demand for automotive electronics – the surge can be credited to the demand for safety systems.

- Growing demand for consumer electronics – new analysis from Frost & Sullivan, finds the growing demand for consumer electronics will increase the outsourcing trend.

- Advanced skill and focus on core competencies – companies are searching for solution providers that provide expertise in their specific field or market sector.

- Proliferation of mobile devices – (The market for Android devices, iPhones and wearable technology is continually growing). Cisco’s annual report on mobile traffic stated, “By 2020, 5.4 billion people around the world will have a phone.”

Applications in the electronics manufacturing space are broad and diverse. Most processes can be applied in any industry for use in the global market. As specified, it includes commercial, industrial and consumer.

Let’s look at a few applications…

Electronics Manufacturing Applications

Medical – Medical OEMs look to their EMS provider to offer not only the best processes and highest quality standards, but the industry expertise and experience that can guide new product introductions seamlessly through development.

Industrial – Industrial applications use many technologies in a wide array of industries. The complete product lifecycle – from scope and specification, through prototyping and testing, to final assembly, these are services needed to bring a new product to market.

Aerospace and Defence – Safety critical solutions are needed for peak performance and high reliability for harsh environment applications. There will be an increased focus on electrification of aircrafts.

Telecom – Telecommunication and data processing is complex. Support is needed for various devices themselves, and the network infrastructure underpinning the technology.

BTG labs, a science-based technology company, shared Typical Applications for Electronics Manufacturing. BTG Labs’ Surface Analyst™ helps electronics manufacturers build a product to stand up to elemental threats.

For instance, if a manufacturer needed a way to ensure the protection of their circuit boards, their instrument would instantly reveal the cleanliness level of the surface. In doing so, “it creates a successful bond between the conformal coating and the circuit boards.”

The manufacturer would cut down on failure and waste while experiencing successful coatings.

Chapter 2

Comparing an OEM to an EMS Provider

The terms used in electronics manufacturing are as different as the roles they play.

OEMs – are known as original equipment manufacturers, EMS – electronics manufacturing services.

For further explanation, Wikipedia defines electronics manufacturing services (EMS) as a term used for “companies that design, manufacture, test, distribute, and provide return/repair services for electronic components and assemblies for original equipment manufacturers (OEMs). The concept is also referred to as electronics contract manufacturing (ECM).”

The market segments are commonly divided into Tiers based on their revenue:

- Tier 1: >$5 Billion

- Tier 2: $500M to $5B

- Tier 3: $100M to $500M

- Tier 4: <$100M

Continuing on…

Have you ever scrolled through an interesting article and you had to “google” the acronym because:

1. You never heard of it before or

- You heard of it, but needed to know its meaning or definition.

Chapter 3

Outsourcing Manufacturing: What You Need to Know

Evaluating outsourcing options begins with knowing your core competencies (the thing you do best). Once you completely understand that aspect, you’ll be able to partner with a provider that offers more expertise and experience in other areas.

How do you know an EMS Company is right for you?

Ask questions.

The process of selecting an EMS provider can be time-consuming and frustrating. But if you know the right questions to ask it can be less daunting.

How to Begin the Process of Selecting an EMS Provider

1. Do they have an extensive history and experience in the industry?

Selecting a manufacturing partner is a tough choice. One major factor to consider is pedigree or credibility within the industry that you are seeking to penetrate or grow. EMS providers that remain successfully operational over many years and decades have often survived because of their ability to satisfy customers in particular markets, year after year.

2. Can they add value to you during the design process?

Most companies in the EMS space offer some level of support through Design for Manufacturing (DFM) processes. Original Equipment Manufacturers (OEMs) should be on the lookout for an exceptionally proactive EMS partner with industry leading toolsets, clear design guidelines, and a knowledgeable and accessible staff who demonstrates the skills required to help bring your product to market faster.

3. Is it obvious that they’ve invested in the latest advanced technologies and modern equipment?

You need to be able to count on a manufacturing partner who supports your business through the use of advanced manufacturing and testing technologies and demonstrates a commitment to ongoing investment.

4. Are they up to code with all industry standards, and then some?

Leading-edge companies will demonstrate a high degree of certification to the latest standards and specifications across all key customer market sectors. Achieving and maintaining certifications in high-reliability sectors requires investment, time, and adherence to stringent processes and business controls; particularly in the Medical, Defence, and Aerospace markets. This in turn shows commitment to a focused group of industries, as well as a dedication to continuous improvement.

5. How comprehensive is their product testing offering?

Product testing should be discussed early in the design stage. For certain products that must operate in particularly harsh environments, environmental and reliability testing should be used to make sure your products will stand up to your intended application.

6. Will they take care of your needs after order fulfillment?

You should feel assured knowing that a dedicated team is available to support aftermarket requirements including service demands and remanufacturing of product. It is important they offer complete product lifecycle support, component obsolescence management and component engineering management services.

7. Is their communication effective and transparent?

Communication with your EMS partner(s) of choice should fall under the three C’s rule: Consistency, communication, and collaboration. The flow of information is paramount to the success of the partnership. This allows open and active dialogue to make business decisions easier and faster.

EMS partners need to focus on ethics and compliance for their corporate brand. Best practices and procedures in their supply chain role will support these efforts.

8. Are they flexible enough to handle your product changes and revisions in a timely manner even if it affects existing production?

A business designed around High-Mix Low-Volume must be able to demonstrate systems and business process capable of reacting to dynamic changes including being able to make changes on the fly.

9. Do they have a new product introduction process in place?

New product introduction covers the entire process of bringing a new product to market. Engineers guide manufacturers and communicate with them through the entire product development process.

Your EMS partner needs to understand how to support this process. They will add value from design reviews, product qualification, volume ramp, and cost awareness. Presence of a dedicated NPI team is an added bonus.

10. Are they a cultural fit?

Knowing your supplier talks the same business language as you and has experience in your market sector speaks volumes. The best manufacturer fit will understand the requirements needed to get the job completed on time, the certifications needed, and in some cases the legalities of working on specific products or programs. Look for manufacturers who can provide customer testimonials that further demonstrate their ability to deliver best in class and support.

11. Do they have a manufacturing footprint that is compatible with your short and long-term needs?

Whether you require local engagement or support for a global market, your electronics manufacturing partner needs to be the right fit for your immediate demand and long-term strategic goals. This will build the relationship both short and long-term.

12. Do they have a product lifecycle management and/or counterfeit prevention system in place?

A robust product lifecycle management program that supports product in the design and development phases is imperative for product success. It should also include obsolescence management that takes into account the lifespan of the components being used, with a plan to replace parts as they age or it becomes a problem.

The EMS provider you choose should combat counterfeit electronic components through prevention. They can do this by procuring parts from a reliable source.

To be considered a true EMS provider, they need to commit to the customer after manufacturing and include aftermarket electronics device repair services.

13. How do they handle traceability?

Traceability is important within the supply chain as it provides the ability to recall components/products, track production and match replacement parts. It gathers the information needed by the manufacturers, suppliers, and distributors.

TT has the capabilities to retain records for those that have specific requirements. Our solutions range from lot traceability to full component level traceability.

14. Does their production mix match those of your products?

When choosing a manufacturing partner, understanding the business portfolio and infrastructure setup allows you to make an informed decision. Questions to review during the process could be:

1. Are they producing computers and cell phones while you are interested in the support of products that may only require 100’s or 1,000’s per annum?

When choosing a manufacturing partner, understand their business strategy and where they are focused in the market.

2. Is their business model built on flexibility and agility or volume and velocity?

15. Do they have a robust voice of the customer program that monitors service levels?

Voice of the customer (VOC) programs describes the customer’s feedback about their experiences with and expectations for your products or services. It focuses on customer needs, expectations, understandings, and product improvement. Making sure that you partner with an EMS provider that is always striving to deliver world-class service at every stage in the process.

16. Do you trust them to be your brand ambassadors?

Outsourcing manufacturing requires substantial trust.

As ambassadors of your brand, it’s their responsibility to execute and support your brand promise. They should be committed to upholding your highest standards of quality by providing a hands-on approach and the technical skills required to meet your most critical specifications.

17. Do they want to strategically align their business with yours?

The executive leadership should be open to a forum on identifying a roadmap for a true partnership. It is crucial that they engage early in the design process and collaborate in every aspect of the relationship, from communication to cost reduction to forecasting.

The partner should proactively provide industry insights and product design expertise and guide clients toward innovative solutions.

Benefits of Outsourcing Your Electronics Manufacturing

One of the top reasons manufacturing companies outsource and use solution providers is to lower their costs. OEM’s can focus on research and development while saving on capital investments. However, another reason is to gain or maintain competitive advantage by improving speed to market.

What are the other top benefits to outsourcing?

Top 7 Benefits of Outsourcing Your Electronics Manufacturing

1.Converting your fixed costs investments to a variable cost model

2.Risk reduction/mitigation

- Speed to market

- Improved productivity

- EMS providers offer more agility

- Greater experience and competence in manufacturing processes

- Much broader and more global supply chain (extension of the global network)

There are over 4,000 EMS providers. Only one is the right fit. They should provide the structure and support mechanisms of a large manufacturer, with the customised, intimate approach of a smaller speciality group.

Chapter 4

Challenges and Barriers – the Dark Side of Electronics Manufacturing

We discussed the advantages of EMS, but there is always another side to the equation.

What are the Challenges Faced by Electronics Manufacturing?

- There is a need for a robust product lifecycle management systems. Without one, manufacturers could make misinformed decisions that affect a product.

- Labour costs are increasing

- There is a need for automation – Ping Qin, Vice President of Marketing, Suzhou RS Technology Co., Ltd says, “We need automation to deal with tasks that require high assembly precision and large assembly quantities.” He continues, “Automated material delivery on production lines is essential. We need automation to replace manual labour in harsh environments.”

- Global competition

- Issues with traceability and compliance

- Disposal of products (E-Waste) and their impact on the environment

- Investment in the infrastructure and support systems to manage complex, highly regulated markets like medical, aerospace, and defence

The challenges are not new, but continue to grow. The integration of the electronics value chain and advanced technology will help break the barrier.

Chapter 5

What is High-Mix Low-Volume Manufacturing

A manufacturing environment that is termed “high-mix low-volume” refers to a large variety of products, often produced in small quantities. The market advantages are two-fold, tailoring to customer demand and lower inventory requirements.

Customers’ expectations are changing for more customised products, which are transferring manufacturing into high-product-mix-low-volume scenario that puts more dynamics in the manufacturing systems.

As stated in the Journal of Advanced Manufacturing Systems,

“Competitive advantage in high-mix low-volume manufacturing environments is driven by the organisation’s ability to effectively plan resource requirements. As the systems are under transformation stage, choosing an appropriate high-mix manufacturing strategy along with the sound tactical thinking is necessary for the 21st century manufacturing that will confer competitive advantage in cost, quality, delivery, responsiveness, technology and services.”

Building complex products in small quantities can be a challenge for OEMs. As such, many choose to outsource high-mix low-volume production to service providers with more experience or expertise in a particular field. Outsourcing production can result in less costly errors, free up internal engineering and R&D resources, and enable greater control of finances.

MPO, Medical Product Outsourcing, has a 7 step process to consider when selecting your EMS supplier: Guide to Outsourcing High-Mix Low-Volume Manufacturing

They agree, “A successful partnership can address the challenges of high-mix low-volume production while also boosting productivity and reducing costs.”

Chapter 6

[Future] Electronics Manufacturing Trends and Opportunities

National Association of Manufacturers (NAM) states, “Manufacturers have experienced tremendous growth over the past couple decades, making them more “lean” and helping them become more competitive globally.”

The electronics sector produces electronic equipment for consumer and industrial industries. The semiconductor industry has grown to become worth more than $400 billion globally, as of 2017.

This rapidly evolving industry leads us to the top trends or opportunities in the industry.

1. We will continue to seek innovative automation solutions.

KUKA understands these growing needs well and is responding fast with new solutions to make robotic automation in this market easy and cost-effective.

2. Rising demand for consumer electronics in both developed and developing nations

This will increase the demand for smart electronics. Here is another innovative technological advancement:

The Robot Revolution: the New Age of Manufacturing

3. There will continue to be the push for more eco-friendly manufacturing solutions.

“Being Green isn’t just for hippies and disaffected Xers any more. As climate change statistics continue to mount, there’s increasing pressure from all areas – consumers, businesses, and governments – to look into more eco-friendly manufacturing solutions. The various carbon cap or carbon trading plans being implemented are also helping to drive this push.” source

4. As an industry, we will develop new methods to produce devices that consume less energy.

According to Pannam Imaging, “Reducing energy consumption is an effective way to cut costs, leading both businesses and consumers to opt for energy-efficient electronics. The pressure is on manufacturers to adopt green manufacturing processes while simultaneously producing electronics that are less expensive to use thanks to lower energy demands.”

Conclusion

Electronics manufacturing is fast paced and always evolving. Flexible solution providers that keep pace with rapid change will continue to experience success for their customers.

RAYMING developed an entire global business process founded on the support of complex high-mix low-volume devices. We are inspired to help solve global electronics manufacturing challenges from design through fulfillment, for customers requiring support for their high-reliability products in high-mix low-volume markets.