The assembly of Printed Circuit Boards (PCBs) comes in different forms, and Through Hole happens to be one of the most used. Of course, it has a specific model of assemblage and that is part of what we’ll be looking at in this article.

What Is Through Hole PCB Assembly?

It is important to understand the underlying concept of Through Hole PCB Assembly before we start looking at other important aspects to it.

Through Hole technology (which is also called Thru-Hole) is the process of constructing and drilling holes into a Printed Circuit Board (PCB). The aim of doing that is to create a hole where leads can be attached on the board.

From another perspective, Through Hole PCB Assembly involves the construction of electronic circuits so that the Pin-Through Hole (PTH) components can be easily drilled or passed through the already drilled /pre-drilled hole into the PCB.

It is important to mention that the Through Hole technology is roundly touted to be an older model, especially when it is compared to the Surface Mounting variant.

That said, the Through Hole PCB Assembly procedure entails that the pre-drilled holes will come in handy in strengthening the components of the Printed Circuits Boards (PCBs) and the boards. Hence, the leads will be there to ensure that none of the components strays off the body of the PCB.

————————————————————-

Request Through Hole PCB Assembly Quote , Pls Send PCB File to Sales@raypcb.com Now

————————————————————-

Types of Through Hole PCB Assembly

There are two (2) main types of the Through Hole PCB Assembly. The first is the Automated Through Hole PCB Assembly. The second is the Manual Through Hole PCB Assembly.

On the one hand, the automated variant is roundly touted to be faster and cost-effective because it takes little time to be completed. It also demands little human inputs, which makes it cost-effective.

On the other hand, the manual Through Hole PCB Assembly involves the traditional or manually-operational model of drilling the holes into the Printed Circuit Boards (PCBs). This model tends to take time and attracts more costs.

Components of the Through Hole PCB Assembly

The characteristics of the Through Hole PCB Assembly are further narrowed down to two components.

These components are discussed below so you can understand them better.

————————————————————-

Request Through Hole PCB Assembly Quote , Pls Send PCB File to Sales@raypcb.com Now

————————————————————-

Radial Leaded Components

Radial Leaded Components are the first on the list. Under these components, the leads that are used therein tend to stick out of both ends.

In addition to that, the Radial Leaded Components take less space, which means that you wouldn’t have to bother about the leads disrupting the entire interface of the Printed Circuit Boards (PCBs).

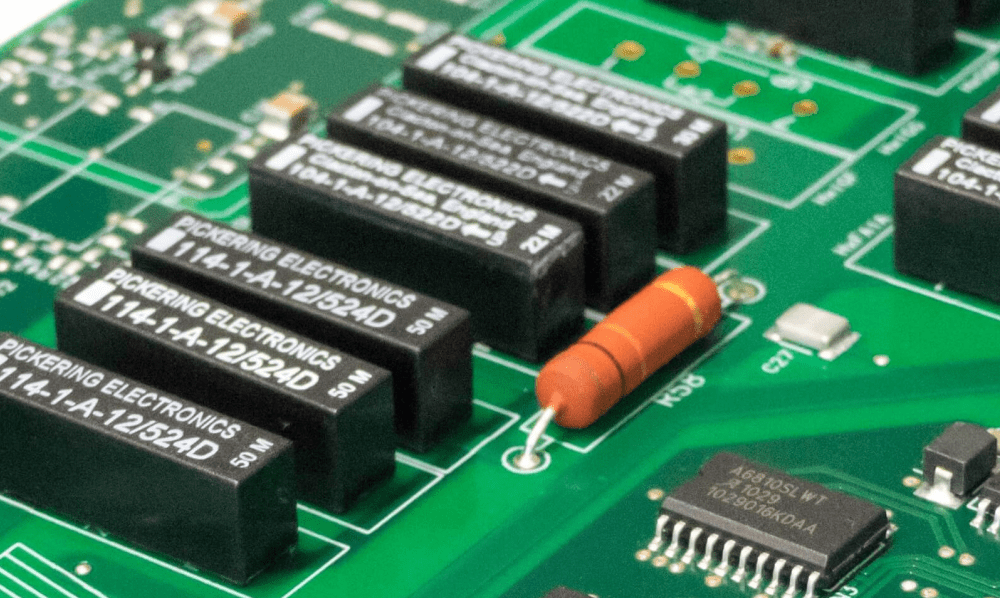

Worthy of mention is that the Radial Leaded Components have specific shapes or attributes by which they are known. Ideally, the components here are designed in the form of rectangular box-shaped figures. They can also come in the form of cylindrical shapes.

Above all, the Radial Leaded Components are packed with many other characteristics, such as inductors, resistors, and capacitors.

Axial Leaded Components

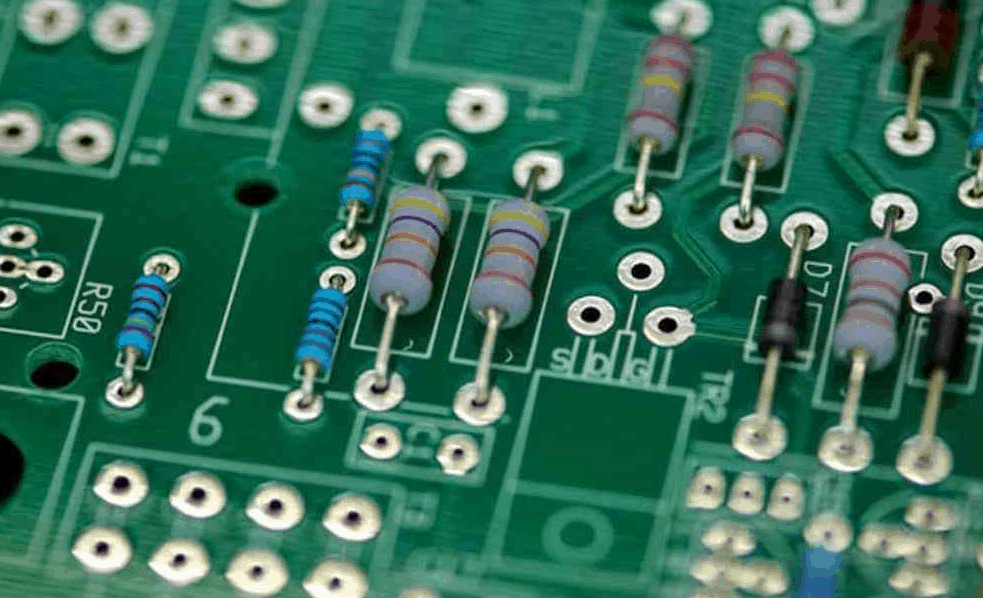

On the other hand, there are the Axial Leaded Components, which take the shape that is similar to that of a symmetrical object. Because of this design and the fact that it can also take the shape of a cylinder, Axial Leaded Components tend to have multiple leads that protrude/stick out from both sides.

The space that the Axial Leaded Components depends on a number of factors, including the position you placed it. Ideally, once the components have been laid unto the Printed Circuit Board (PCBs), they tend to have their wires fitted through a hole.

The components that are used here include but are not limited to capacitors, resistors, and inductors.

————————————————————-

Request Through Hole PCB Assembly Quote , Pls Send PCB File to Sales@raypcb.com Now

————————————————————-

Benefits of Through Hole PCB Assembly

Why does Through Hole PCB Assembly have more use cases than the competitor – the Surface Mounting?

Below are some of the importance and benefits of using the Through Hole PCB Assembly:

Higher and Advanced Heat Tolerance

Because of the potential use cases, such as in the aerospace industry, it became important to ensure that the Through Hole PCB Assembly is heat tolerant.

The heat tolerance is bolstered by the advancement of the technology that is used to facilitate that. In addition, the high tolerance heat capability comes in handy to protect the products manufactured with it when there are environmental disorders and extreme collisions.

Easier Prototyping

Because of the massive adoption and use of the Through Hole PCB Assembly, there are more tendencies of more use cases. In the same light, the prototyping needs to be completed in good time to meet the demands.

To that end, the easier model of prototyping the Through Hole PCB Assembly is one of the factors that bolster the preference over the other – Surface Mounting.

In this instance, the reliability of the prototyping model ensures that the components of the Through Hole PCB can be easily swapped or exchanged.

Superior Power Handling

The superior and stronger hold that the Through Hole components form with the Printed Circuit Boards (PCBs) informs the reason behind the superior power handling. That is also because the relevant components are easily passed through the PCB before they are attached to the board using metal solder/lead.

Besides, that basis makes the Printed Circuit Boards (PCBs) in question to be in better positions to be used for larger components. More so, the strength of the PCBs tends to come in handy when there is a need to be used under high voltages and high-risk electrical conditions.

Durability

Because of the superior power handling and the strengthened bond between the Through Hole components and the Printed Circuit Boards (PCBs), it means that the boards and the components will be more durable.

Therefore, when you are using the Through Hole PCB products, you can every confidence that they will last longer than the counterpart – the Surface Mounting.

Final Words

Through Hole PCB Assembly is a commendable innovation in the Printed Circuit Boards (PCBs) market. That is because it offers many features that aren’t tenable in its competitive variant – Surface Mounting.

Are you ready to use Through Hole PCB Assembly for your next PCB projects? Let us know your thoughts in the comment section!

Comments are closed