An Introduction to ABF

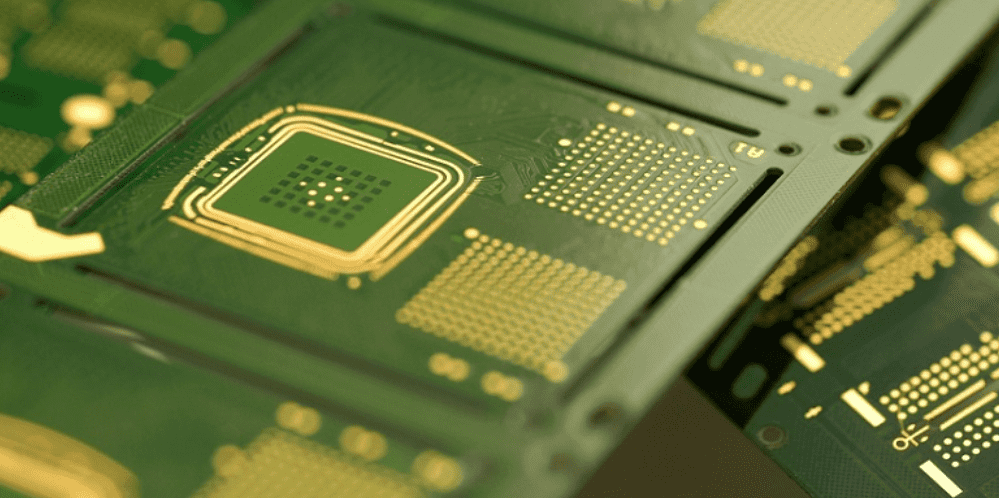

ABF stands for the Ajinomoto Buildup Film and is an essential component in most personal computers globally. You might not know about it but people who are into technology and detailing understand its significance in computers. ABF in a set of multiple film dielectrics. These thin dielectrics provide electrical support and insulation to the circuit substrate. This insulation boosts the CPU’s performance and computers operate better. ABF PCB are working for years now, but advanced versions have been used in recent years. The world has become a global village and without technology, there’s no life. The ABF substrate ensures the integration and configuration of devices.

ABF is an old and essential component manufactured and used since 1970. The manufacturing of ABF took years, and ABF integration in computers dated back to 1990. ABF was initially a very basic component, but scientists brought great improvements to it over time. It is majorly applicable in chip manufacturing, and it’s evolving every year. The transition of personal computers from MS-DOS to WINDOWS was a prime factor in manufacturing ABF substrate. ABF PCB is being applicable in grand yield control units. Without these substrates, controlling yield becomes crucial. ABF polymers include several layers of microcircuits that interface between the nanoscale CPU and PCB.

What is ABF PCB?

PCB refers to Printed Circuit Board also known as PWB Printing Wiring Board. It works as a medium to build a connection and support between electronic components. PCB operates like a controller to make the components work in balance. It is manufactured and placed as a laminated structure and used to insulate the chips’ layers. The layers are structured as artwork and exist in various patterns, traces, and surfaces. The patterns and materials used for PCB fabrication are a challenge for engineers and designers to make a suitable substrate for a computer.

The first ever PCB was used in the UK back in 1936, but after various interventions, engineers started using it in personal computers after 1990. PCBs are rigid and small in size but flexible enough to produce high-density connections. Advanced 3D printing is a result of high-quality PCB creation. PCB can be used in multiple layers of a 3D printer to get a final form with electrical functions. The plants and manufacturing companies for ABF PCB are mostly located in Taiwan, China, or Japan.

Uses of ABF PCB

- ABF PCB can be utilized as an insulator in all modern personal computers.

- It is used to expand, contract, and resist the temperature of the processor.

- ABF PCB is essential in creating and designing smaller components of the CPU.

- PCB is a versatile alternative to common electrical and biomedical engineering.

- ABF PCB circuit can be directly attached to a copper foil substrate without thermal pressing.

- High-end CPU, GPU, and Chip sets use ABF as an additional layer material for smooth functioning.

- ABF PCB is majorly used in manufacturing the chip for base stations, routers, and computers.

- It works as a semiconductor in processing and optimizing modern computers.

- The ABF substrate provides precision via nanoscale and milli-scale buildup for fast functioning.

- ABF PCB Substrates are used as agents of coating as resins for the electronics and tech industry.

- PCB components are used to interconnect the computer’s system and motherboard on the millimeter scale.

- ABF integration is essential to comprise the interface between CPU and PCB polymers.

- The film features technical properties showing low thermal levels and great durability.

- ABF PCB is a high-performing chip resulting in repairing defective devices and sizing RDL.

Top 10 Manufacturers of ABF

ABF PCB is an advanced and popular film substrate for personal computers, routers, and CPUs. Various manufacturers around the globe are using this technology. Here’s a list of some amazing manufacturers of ABF and PCB. Apart from the 10 we are listing down, many other companies manufacture ABF PCB substrates. This has become a huge market now as the world is experiencing a tech revolution. PCB and Ajinomoto Build-up Films are globally used as a package substrate for insulating layers in the CPU.

1. Unimicron (Taiwan)

2. Ibiden (Japan)

3. Nan ya PCB (Taiwan)

4. Semco (Denmark)

5. Shinko Electric Industries (Japan)

6. Kinsus Interconnect Technology (Taiwan)

7. Kyocera (Japan)

8. TOPPAN (Japan)

9. Shennan Circuit (China)

10. Zhen Ding Technology (Cayman Islands)

Characteristics of ABF PCB

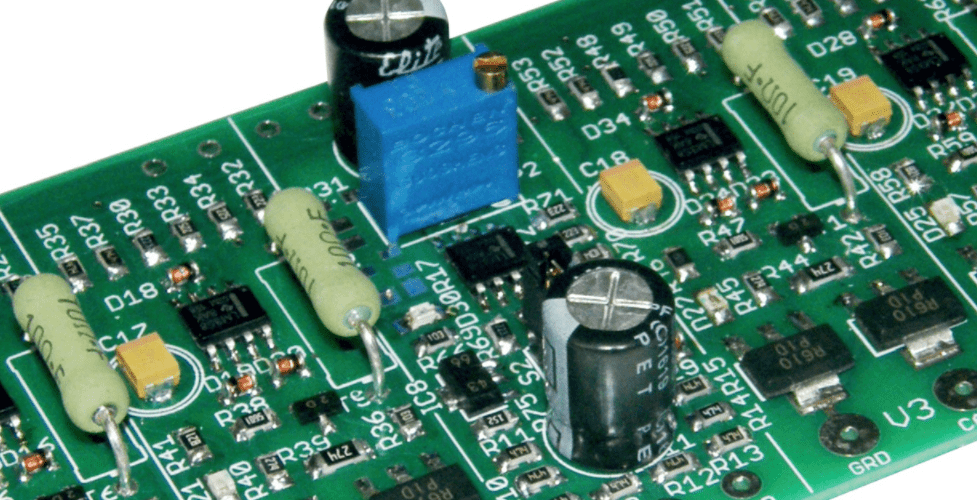

ABF PCB is a non-conductive substrate material used according to the dielectric constant value. These substrates are an amalgamation of composite structures including epoxy resin and paper glass fabric. The printing circuit board industry is evolving day by day. Multiple solid and flexible substrate components are now being used. With a strong solid PCB base, fiberglass polymers can give great and long-lasting results. Fiberglass is one of the most economical yet reliable materials. The correct setting and support operation can be done efficiently if all the materials and substrates are being used in PCB manufacturing.

Some of the technical characteristics are as follows:

· Dielectric Constant

· MOT (Maximum Operating Temperature)

· Insulation through Electric Substrate

· Thermal Processing & Conductivity

· Efficient Therman Expansion

Some substrates are flexible, some are rigid and a few are semi-rigid. The flexible substrate is the engineer’s prior choice because it’s foldable. The rigid PCB is usually used in high-end medical, aerospace, and military sector devices for lifelong work. The consistency of the PCB is decided according to the placement and climate changes of the region.

Conclusion

ABF PCB is an essential component for personal computers and mobile, automotive, and grand infrastructure. It works as a semiconductor for the fast and better functioning of devices. Ajinomoto Build-up Films is not only important for the tech industry but it is now considered a significant substrate in various sectors. The quality and functioning of ABF PCB are improving over time with the rapidly upgraded versions of CPU and other devices. Learn more about ABF PCB to achieve thermal stability and processor optimization. ABF PCB is evolving and diversifying its work to fulfil customers’ requirements. Since the use of ABF, Manufacturers are experiencing fast growth and better functioning of devices.

Comments are closed