You must have heard about the purple PCB, the red PCB and the standard circuit boards that use the green solder mask. The general idea is that the core differences between these circuit boards is the color, i.e., the color of the solder mask.

While it is common to use the green solder mask, it is more than possible to have the PCB in other color variants. Today, we will be discussing the blue PCB and comparing it to some of the other circuit boards in the market.

What is a Blue PCB?

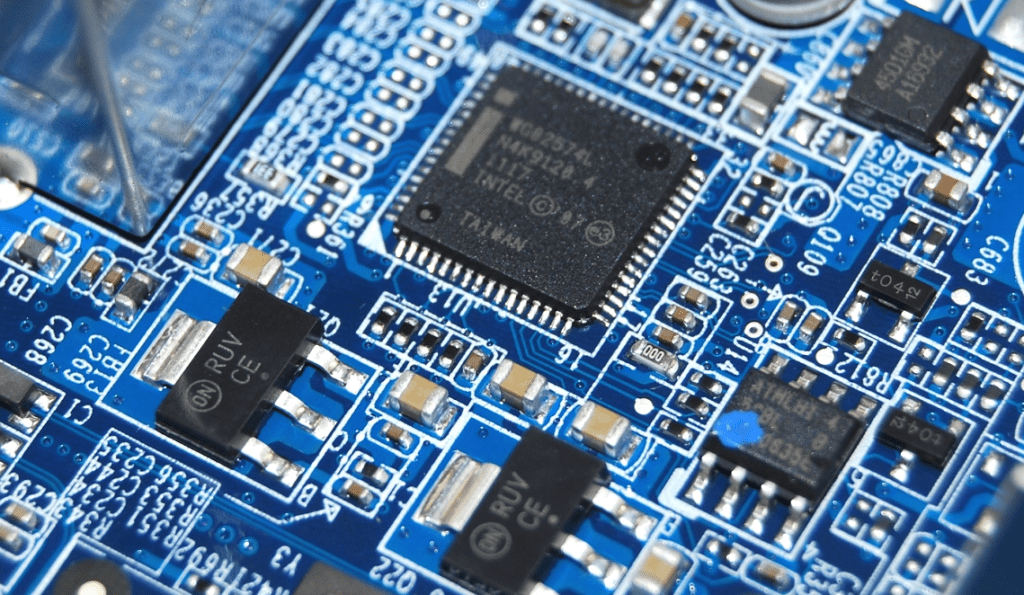

Also called a blue Printed Circuit Board (PCB), it is a type of circuit board with blue as the solder mask color. But if we are to look beyond the color, we will see that the blue PCB has some unique features.

The core attribute of the blue circuit board is the enablement of the assembly of electrical circuits or data into one hardware. That way, you will have most of the properties you need to get the job done in one place.

It is also pertinent to mention that the blue PCB improves the connectivity options of the circuit board, in terms of offering the required mechanical support and an extensive electrical connection capability via the conductive pathways.

Does the Color Really Matter?

It appears that the blue PCB has better features that go beyond the color – blue. The remarkable thing about the color is that the circuit board shares a similar color as the solder mask, which is blue in color.

In light of this, the blue PCB can pass for not just a dyed circuit board, but also one that ensures the accurate protection of the copper wires placed on the Printed Circuit Board (PCB).

Unique Attributes of the Blue PCB

Below are some of the unique attributes or characteristics that make the blue PCB better than some of the other circuit boards using a different kind of solder mask:

1. Metal Detection

It may have been imagined that the blue hue of the PCB would make it impossible to detect some components. On the contrary, the blue color of the blue PCB makes it possible to see the metals on the surface.

2. Excellent Routing Capabilities

The blue solder mask also aids in the routing of the communication and power components, across the hardware components.

3. Excellent Extraction

There are times when some components or stretched parts need to be extracted and fixed. If the solder mask of the PCB makes it unclear where these parts are located, it could lead to usurping the other components while in search of the main parts to be extracted.

However, the job is easier with the blue PCB, which allows for the faster location and extraction of the stretched parts without negatively affecting the performance of the other circuit board components.

Design Considerations for the Blue PCB

If you must work with the blue PCB, we think you should also take note of some of the important design iterations. Here are some of those considerations:

Metal Placement by Soldering

Soldering the metals unto the board is the major processes for getting components, especially metals on the circuit board’s surface.

Ideal for Complex Applications

The blue circuit board is a better choice for complex or complicated electronics projects, such as RC robots.

Magnification is Important

While it is easier to inspect the metals by merely looking at the surface of the blue PCB, the same cannot be said of the other components.

Ideally, magnification is required to put these other components into perspective. The following are some of the reasons why magnifying the blue circuit board is important:

- It helps the designer to make closer inspections, especially for the following: traces, the shallow contrast between the planes and the empty spaces on the circuit board.

- Magnifying the blue PCB is a faster way to put the malfunctioning components into closer glance and help rectify the manufacturing fails or defects on time.

Assembling Processes for the Blue PCB

If you are looking to assemble the blue circuit board, a couple of technologies can help you do that. Below are some of the assembling processes:

Electro-Mechanical Assembly

This can be best be described as the “fusion of electronic and mechanical assembly processes.” Also called the Box Build Assembly, the electro-mechanical assembly process for blue PCBs aids in the usage of specific parts or components to assemble or couple the blue PCB with the other components.

The examples of components used for this purpose include:

- Cable assembly

- Custom metalwork

- Wire harnesses

- Molded plastics and;

- Looms

Surface Mount Technology (SMT)

This involves the use of the Surface Mount Devices (SMDs) to place the required blue PCB components on the board’s surface.

Another benefit of the SMT process is that it improves the circuit’s density, considering that it allows for the double-sided placement of the components.

Plated Through-Hole

This process is based on the Through-Hole Technology (THT), which has to do with the drilling or making of holes into the lead-tipped components.

Other drilling options include:

Via Holes

This drilling format involves the making a plated through-hole on the blue PCB to enable the joining of a trace on the top surface of the circuit board to the other traces inside the circuit board.

Electro-Coating

This involves the drilling of holes on the surface of the circuit board before applying copper in the drilled holes.

Blue PCB Stackup

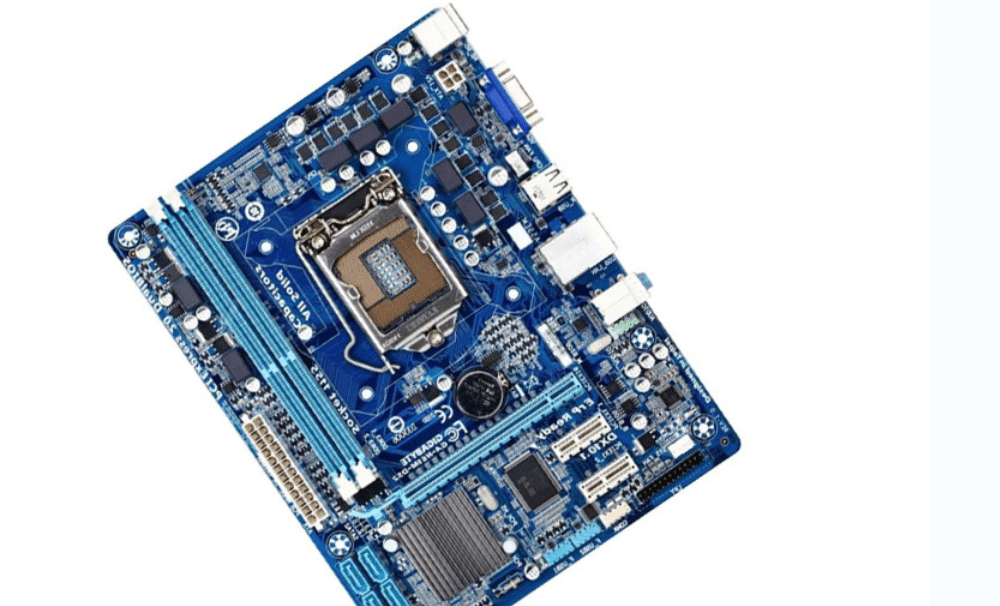

How does the blue circuit board stackup or what is the structure? The circuit board is usually modeled as a stack of layers upon another.

Below are the core stackups of the blue circuit board:

- FR4: this is the base material and serves as the material that improves the blue PCB’s thickness and rigidity.

- Copper: this material is glued to the blue PCB after the FR4.

- Solder Mask: this is the color of the topmost layer and in this case, it has a blue hue, which is why the blue PCB is so-called.

- Silkscreen: this is usually the last stackup for the blue PCB, before the components are placed or mounted on the board. The silkscreen details the numbers, letters and any other indicators that make assembling the PCB easier.

Wrapping Up

The blue circuit is much more than just having a blue (solder mask) color. It also has numerous advantages, such as wire reduction and the easy identification of metals. The blue Printed Circuit Boards (PCBs) are typically used with the defensive, military, LED lighting, electronic communications and aerospace applications.

Comments are closed