AISLER PCBlectronic products being produced. Typically, it can take anywhere between a few hours and a couple of weeks, if you are making prototypes of full production of the electronics.

These days, it has become a practice to use the services of full-suite companies that offer most of the electronics manufacturing. These are called the Electronics Manufacturing Service (EMS) companies

What is an EMS Company?

An Electronics Manufacturing Service (EMS) provider is a company that offers most of the services required for assembling electronic products. These services range from the design, production, testing and designing of the electronic companies.

The EMS company can also engage in the services of distributing, returning, and repairing of the electronic components and the assemblies required for the Original Equipment Manufacturers (OEMs).

The EMS Lacuna

The concept of Electronics Manufacturing Service (EMS) was developed to facilitate the speed and processes/techniques at which electronic components and related assemblies are produced and distributed.

However, it has become clear that the system is laden with challenges, ranging from the inability of the EMS company and the concerned parties to work as one. The EMS provider might also be having issues with meeting the order fulfillments on time.

It is therefore, on that background, that the EMS service offered by AISLER PCB can be the gamechanger. Read further to find out how this company intends to go about it.

About AISLER PCB

With the commitment to bolstering “electronics manufacturing for humans,” AISLER PCB ensures that the EMS industry is in top shape.

The company promises to “empower agile electronics development by simplifying and speeding up electronics manufacturing services.”

The company’s major goal is to “make electronics manufacturing services accessible to everyone.” Irrespective of your location, EMS specifications and the type of electronics you want to produce, rest assured that AISLER PCB has what it takes to bring your ideas to life.

Solving Industry Challenges

It is pertinent to mention that one of the major reasons why the EMS services offered by AISLER PCB thrive is because the company understands the current lacuna in the industry and has solutions for the same.

Here are some of the solutions AISLER PCB has offered to address the widening gap in the Electronics Manufacturing Services (EMS) market:

Collaborations with Dispatch and Quality Control Companies

One of the banes to EMS is the inability to ship the completed electronic components on time. Understanding how this last-mile delivery challenges can usurp its service offerings, AISLER PCB opted to collaborate with other companies.

As per the information on the website, AISLER PCB partners with both the dispatch and quality control locations, as well as with the certified manufacturing partners in Germany (Europe) and the United States.

With these collaborations, AISLER PCB hopes to offer both deterministic and affordable delivery solutions for the electronic components.

Besides, these collaborations also help the company to get over the supply-chain shortages, import tariff issues and local import custom hassles.

AISLER PCB’s EMS Services

In this section, we give a breakdown of the different Electronics Manufacturing Services (EMS) that AISLER PCB offers.

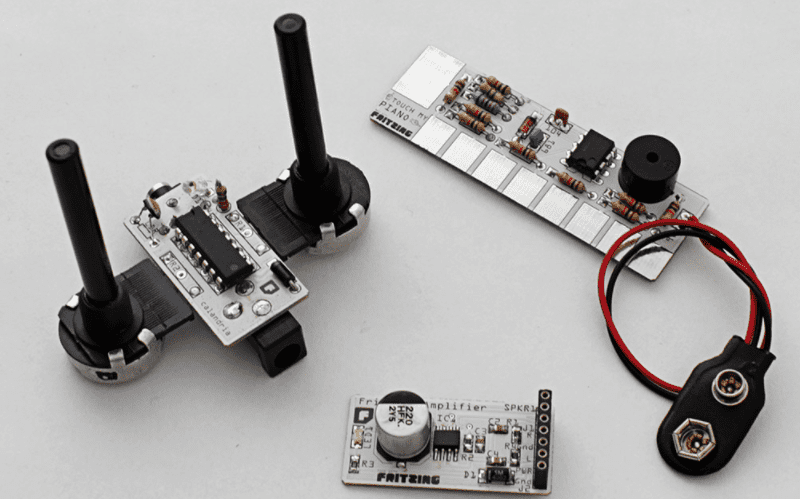

1. Component Assembly

AISLER PCB helps assemble the components for your electronics. Whether you have a prototype already or not, you can rely on the company to scale up your circuit board designs.

Here are some of the things you need to know about the component assembly offered here:

- Partial Assembly: AISLER PCB understands that for some reasons, customers would want to play a role in the assembly of their electronic components. That’s fine. You are allowed to take part in the process because of the company’s offering of partial assembly – so you get to do some work!

- Transparent Pricing: want to know what it would cost to have your electronic component handled by AISLER PCB? You can use the pricing section on the page to calculate the following: number of sides for the components, the quantities, board area, and part variance. You can also factor in the unique components, the SMT components and the THT components to get the right pricing for the project.

- Complex Component Integration: complex components can also be integrated with ease with the not-so-complex components. With the Amazing Assembly AISLER PCB offers, you can add the complex components into the smallest of circuit boards.

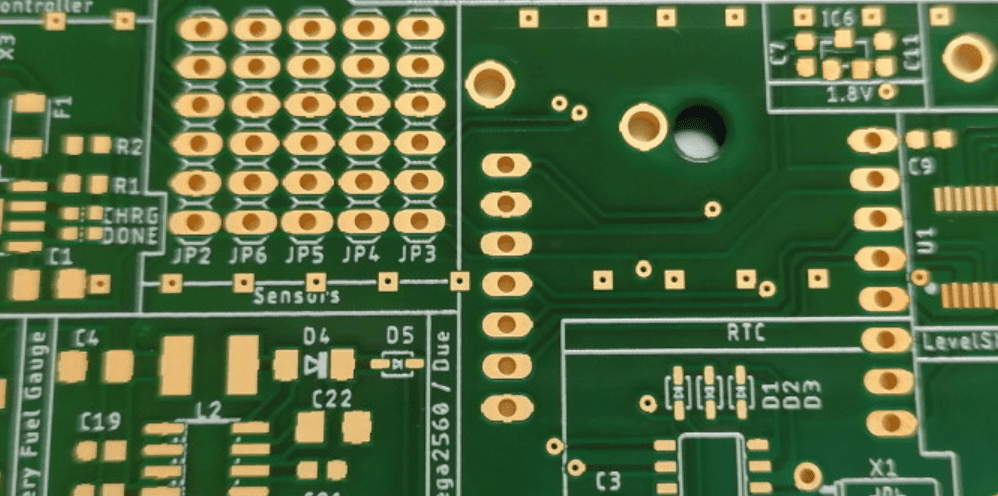

2. PCB Manufacturing

AISLER PCB also engages in the production of Printed Circuit Boards (PCBs), albeit, at the most affordable costs. With as little as €12.13, you can have an industry-grade PCB manufactured for you.

These are some of the advantages of the PCB manufacturing service offered by AISLER PCB:

- Flat Rate: AISLER PCB discovered that some EMS companies charge differently, depending on the additional circuit specifics, such as ENUG finish, inner millings, extra drills and plated holes. That informed the reason why AISLER PCB opted to give a Flat Rate, which is hinged on charging for circuit board production by the dimensions. With this, customers get to enjoy the following: green soldermask with ENIG finish, unlimited plated and unplated holes, as well as unlimited inner and outer millings.

- Version Control: AISLER PCB introduced a concept called Version Control, as a way to reduce the hassles of making PCB prototypes that differ from the project’s version. With the Version Control, you can be sure to get exactly what you had in the project version or the online renderings of the circuit board project.

3. PCB Stencils

With the service called Stellar Stencils, AISLER PCB helps customers to speed up the process of soldering Surface Mount Device (SMD) components.

Rather than just sticking to the manual processes, the company came up with a PCB stencil solution that speeds up the process, while saving costs.

Here are some advantages of AISLER PCB’s Stellar Stencils’ service:

- Charged by Dimensions: AISLER PCB doesn’t charge you by the pad counts, but rather by the dimensions of the stencils. That way, you wouldn’t have to be charged for using more pad counts on the stencils.

- Double-Sided Stencil Production: AISLER PCB also produces double-sided PCB stencils, via the automatic detection of spaces on both sides.

- Framed Stencils: AISLER PCB makes framed stencils, which are PCB stencils with a lot of space. The company promises to keep the stencils at the following dimensions: 25mm on both the left and the right-hand side of the stencils, 50mm on the top and 40mm on the bottom of the stencils.

Final Words

The Electronics Manufacturing Services (EMS) market just received a major boost with the unique services offered by AISLER PCB. You can be sure that this manufacturer has the network and capabilities to bring your PCB designs to life in the shortest time possible – and at affordable pricing options.

Comments are closed