Engineers and designers try hard to improve the functionality of Printed circuit boards. These circuit boards are the heart of electronic devices. Every day there is a different technique to improve PCBs and their related issues. Hard Gold plating is helpful in solving many issues related to PCBs.

Gold is one of the best materials for surface treatment during PCB manufacturing. Gold has unique properties such as conductivity, less oxidation, no corrosion, and longer shelf life. That’s why it is ideal for PCB design and surface finish.

Nowadays, the electronic industry is growing day by day. That’s why it encounters various challenges like pollution, moisture, corrosion, and other external issues. The longer life span of devices and machines is another problem for PCB manufacturers. Ultimately all these factors affect the reliability of electronics. Gold PCBs help to resolve these issues and improve the functionality of the product. The below content will help you to know more about gold PCBs.

What is a hard GOLD PCB?

Hard gold PCB has different names, such as Electrolytic Nickel, Electrolytic Gold, hard electrolytic gold, hard gold plating, etc.

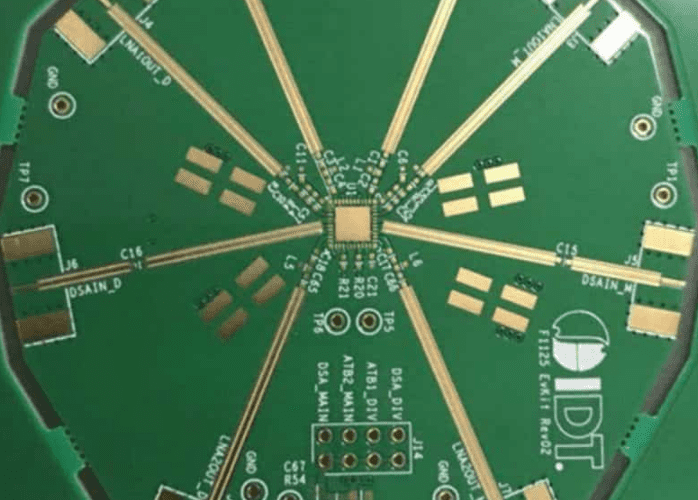

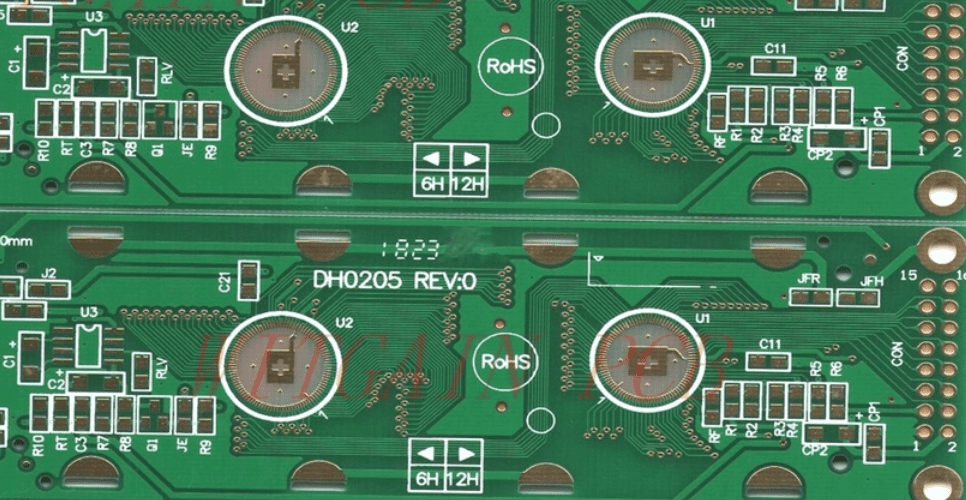

This hard gold plating provides circuit boards with contact points through edge connectors. These PCB edge connectors are also called gold fingers. If you open a computer’s PCB, you will find a neat, narrow, and long row of PCB pads on the edge. Due to the rectangular shape, these gold edge connectors are famous as gold fingers. These hard electroplated gold fingers save the edges from destruction.

Usually, when PCBs are repeatedly installed and removed, then their functionality is affected. That’s why PCB gold fingers provide better connectivity and less wear and tear. You may notice that computer RAM has gold fingers. That’s why RAM can withstand repeated usage and has fewer scratches. Let’s dig deeper to know more about the hard gold plating PCB (gold fingers).

Process of hard gold-plating fingers

The gold fingers plating process has different steps. It starts right after the application of the solder mask. Sometimes this process starts just before the surface finishes. The next step is the application of the nickel layer. In the past, when there was no gold plating, then it was hard for the nickel layer to stay for a longer time.

After that, gold is plated on the nickel layer. Sometimes the copper layer provides additional strength. Gold protects both nickel and copper layers.

Now gold fingers are ready for edge beveling. This process creates smooth edges so that gold fingers can become edge connectors. These edge connectors help to join the circuit board to another circuit board. In this way, more than one PCB can join with one another. Sometimes complex products require more than one PCB interconnection. So at that time, these folded fingers serve the purpose.

Difference between hard gold plating (gold fingers) and immersion gold (soft gold plating)

Many people confuse both hard gold plating and soft gold plating. They are both the same. Actually, both are different in terms of manufacturing and uses. The electrolytic process is also different for both.

Hard gold-plated PCB

Hard gold electroplating is a technique that is helpful in giving strength to PCB. Gold and some other metals are mixed to achieve a harder deposit with a more refined grain structure. Nickel or cobalt is the most common alloying metal.

You can’t use gold alone for this purpose; that’s why you have to make it alloy by combining it with some other metals. Hard gold is extremely durable, so it is most commonly applied to high-wear areas such as gold fingers. The hard gold plating surface is smooth and shiny .Gold thickness varies for a diffusion barrier coat. The lowest gold thickness must be 0.5 microns. The high gold thickness provides the best PCB surface finish.

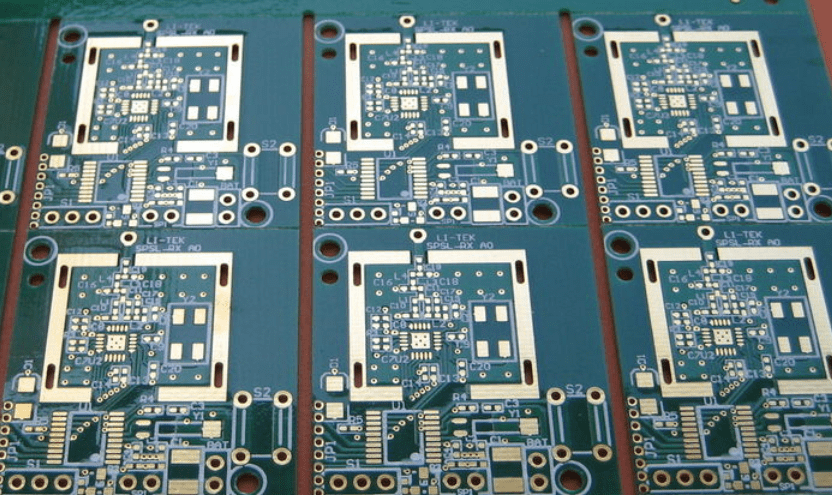

Full Body, Hard Gold plating is a rarely-chosen surface finish by a PCB manufacturing company. Mostly selective hard gold plating PCB is one of my favorite techniques. Selective gold plating is more cost-effective rather than full-body electroplated gold PCB design.

What is soft immersion gold?

Immersion gold, aka soft gold plating is also an electroplating technique. In this technique, gold is pure without any alloy. As gold has high purity, so it doesn’t have a strong grain structure. Soft gold plating produces a more coarse grain structure. That’s why immersion gold PCB has a soft surface finish with a darker appearance. Similarly, its good oxidation resistance is due to the presence of pure gold. Pure gold provides highest oxidation resistance

Differences

- Soft gold plating has good adhesion, so it is used on chip-on-board. It has better signal connectivity, so it is part of many medical machines and sensitive devices.

- Hard gold is not generally applied to solderable areas because of its high cost and its relatively poor solderability. Poor solderability means it’s hard to make holes and joints in the metal. But On the other hand, hard gold plating is extremely durable.

- Hard gold-plated PCBs are Durable and best for high-wear equipment. That’s why high-wear areas have PCB gold fingers. However, their manufacturing process is complex.

- Hard gold plating provides surface hardness. Furthermore, it saves the surface from friction. It has the drawback of poor solderability. So it is useful for places where soldering is not necessary but subject to extreme friction. That’s why you see hard gold plating on specific areas of memory cards and printed circuit boards. The gold plating on PCB is in a rectangular form, such as gold fingers. You may be wondering why all PCBs are not gold-plated. Manufacture made full body hard gold PCBs according to need.

- Hard gold provides a perfect PCB surface finish. It would cost you a lot if you want to cover the entire board with gold plating. Furthermore, it is not necessary to cover all PCB with hard gold plating. So selective Gold plating not only reduces the use of gold but also saves money. Further, it enhances product performance.

- So hard gold plating and soft gold plating are different in terms of thickness, properties, and uses.

Tips to Choose the Right Gold Plating technique for the PCB

If your PCB or product has to face friction, hard gold plating is best because hard gold plating has hardness and friction resistance.

Friction resistance

For example, memory cards and rams. These are mostly prepared with these techniques because they require repeated sliding. Similarly denser crystal structure makes it suitable for abrasion resistance. Further, it provides good wear resistance. Repeated sliding doesn’t affect their functionality because hard gold fingers protect their edges.

Soldering requirement

If your product or PCB needs soldering, then don’t go for hard gold plating. Soft gold plating is suitable for soldering, soft joints, and sensitive connections.

Adhesion

If you require adhesion, then again, go for soft gold plating. Similarly, if you want corrosion resistance, then go for soft gold plating. Gold has the highest purity in soft gold plating, so it reduces corrosion. It increases the life of the PCB and, ultimately, the life of the device.

Suppose there are chances that your PCB can face resistance that doesn’t go for hard gold plating. Hard gold plating PCB will increase the contact resistance. That’s why soft gold plating or immersion gold plating is best. But their corrosion resistance is unmatchable.

Appearance

Soft gold plating has a darker appearance, making it easy to scratch. So hard gold plating is suitable for devices and PCBs that may encounter friction and scratches. So gold plating technique depends upon the requirement and type of product. You cannot put gold fingers in every other product, or you can’t use the immersion gold technique for every solder-able PCB

Uses of hard gold fingers in different appliances

Hard gold fingers have multiple uses due to their hard gold plating. Mostly the computer industry and high-end user products have gold fingers or hard gold PCBs. Hard gold plating is suitable for high-wear products. It is also suitable for visible interconnect applications. That’s why PCB gold fingers made perfect interconnect applications. Due to the advancement in technology, their use has increased. That’s why their manufacturing industry is growing fastly.

Wrapping up things

I hope this content helped you a lot to know more about hard gold plating and how it is different from soft gold plating. Nowadays, it’s really hard to find reliable manufacturers for gold plating.

If you are looking for a reliable PCB manufacturer, then Swimbi PCB provides some of the most innovative PCB technologies. Their hard gold-plated PCBs are extremely durable and also provide extreme corrosion resistance. Their excellent quality control makes their PCB design unique. They are competent and experienced PCB manufacturers.

They can manufacture PCB boards to meet your demands, from hard gold plating PCB to electroless nickel immersion gold PCB. Additionally, they can serve your needs for hard gold PCBs, even for the most complex PCB designs. That’s why they are the best in town.

Comments are closed