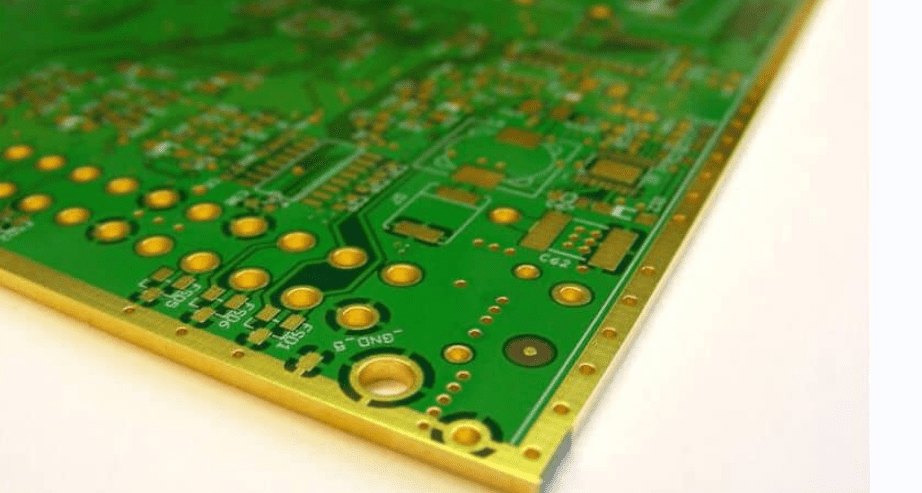

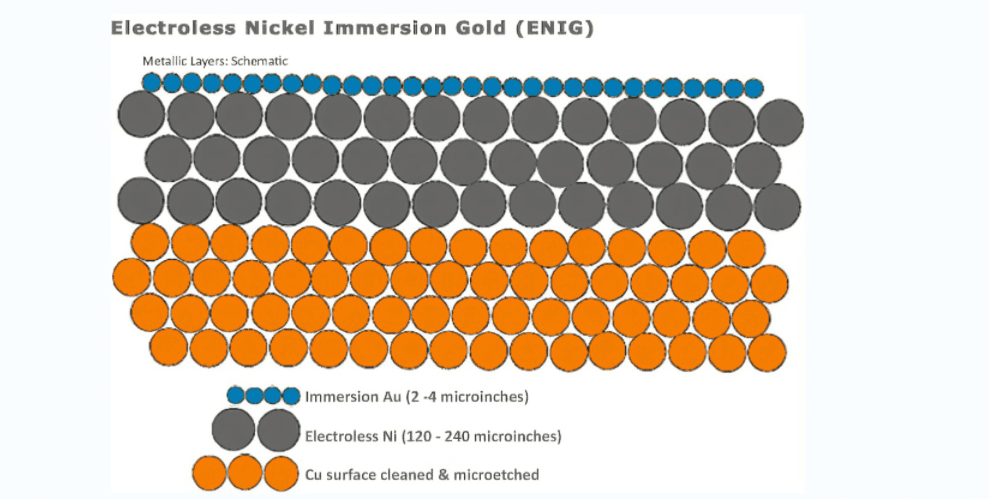

Printed circuit boards are part of countless electronic and digital devices. Nowadays, PCBs are gold plating by different techniques. It is different form hard gold plating. Immersion Gold plating, aka electroless nickel immersion gold (ENIG), is one of the electroplating techniques. This process requires a very thin application of the gold layer. The thickness of a very thin layer varies between three to nine micro inches. Hard gold plating has more thick gold layer.

Before getting into the immersion gold, you must know about the ‘surface finish technique. This technique provides a surface with a smooth and shiny appearance depending on the material. Surface finish is the smallest movement, such as covering a surface with a coat of pain. , so the shiny part of many electronic devices is usually immersion gold. A thin layer of gold prevents the oxidation of the copper layer. It is very important for developing the smallest electronic parts. It also provides the smallest parts with high flatness. High flatness is not possible with hard gold plating.

Let’s dig deeper to learn more about Immersion gold plating and its uses

What is Immersion Gold Plating?

Immersion gold plating is a surface finish plating technique. Its excellent corrosion resistance makes it ideal for many appliances. Immersion gold plating makes gold wire bonding easy. Gold wire bonding helps in the connectivity of parts. In the process of electrolytic gold plating, the gold layer is applied over the nickel layer through displacement. This process continued until the gold layer covered the nickel layer completely. This thick gold layer protects the nickel from oxidation. The typical gold thickness ranges from two to nine micro inches. This gold thickness remains consistent throughout the PCB.

If you want to get high-quality immersion gold plating, then control the concentration of the gold salt in the plating bath. You can control the concentration of the gold plating bath by measuring the conductivity of the solution. Sometimes atomic absorption spectroscopy also helps to measure the conductivity.

Why is Immersion Gold plating so popular?

Hard gold plating is one of the modern surface finish plating techniques. Immersion, gold Plating solution, is expensive because gold has the highest purity for surface finish. Still, this is popular due to the following reasons.

Corrosion resistance

Corrosion is a natural process for metals. It converts metal into stable oxides. We all know how corrosion affects the functionality and life span of any product. In the past, corrosion was one of the reasons for PCB failure in many products. Immersion gold plating shows unique chemical properties, such as longer shelf life and almost no corrosion or erosion. Gold layering saves nickel and other parts of PCB. That’s why immersion gold plating provides excellent corrosion resistance.

Good adhesion

Immersion gold plating provides good adhesion due to excellent adhesive properties. Strong adhesion properties make it ideal for many electronic or digital devices. You can connect gold-plated PCBs easily with other surfaces.

Excellent solderability

Immersion gold plating provides good plating around the holes in the circuit board. It provides excellent solderability. The immersion gold plating is gold wire bondable, that’s why it has excellent solderability. Immersion Gold has a different crystal structure compared to hard Gold Plating, that’s why it is easy to weld immersion gold. As a result, it doesn’t cause bad welding.

Less oxidation

The gold layer saves the nickel layer from oxidation. In the absence of a gold layer, the nickel surface can react with the oxygen present in the air. As a result, nickel can easily oxidize. Immersion gold plating saves nickel from oxidation. That’s why gold plating board is part of many electronic and digital devices. Oxidation affects the functionality of the device.

Wide use in different applications

Immersion gold plating PCB is the solution to many problems related to electronic and computer devices. Immersion gold boards are suitable for many devices in every field, such as motherboards in computers and the medical field. It is also valuable for protecting medical equipment from corrosion and rust. Immersion gold boards improve signal transmission and the service life of products.

It gives PCBs long life

In the past, many devices and machine failures were due to the low quality of PCB. Corrosion and oxidation reduce the working capacity of PCB, and ultimately it affects the device functionality. Gold immersion plating provides a solution to these problems and increases the lifespan of PCB.

The least exposure to lead

Immersion gold plating covers the nickel and copper layer. High lead levels may bring about several complications, so immersion gold save manufactures form harmful full side effects.

Who can do the best immersion gold plating?

You can find numerous companies performing PCB manufacturing and gold plating. Selecting one of them is really hard, and a small mistake can ruin your PCB. That’s why it is very imperative that you get your PCBs coated by a leading manufacturer. The Swimbi PCB provides the best solution for all your PCB-related problems. They have the latest technology and expertise in every type of PCB manufacturing. They are the market leaders, whether immersion gold or hard gold plating. So now it’s up to your requirements whether you go for immersion gold or electrolytic gold plating. Both electroplating techniques have their pros and cons. A layman needs clarification on both techniques when it comes to choosing one. Swimbi PCB can suggest the best technique according to your PCB needs.

Wrapping up the things

All the advantages mentioned above will explain why you should go for this immersion gold plating. Immersion gold plating is a plating technique for PCBs. It is a different technique and offers different characteristics compared to hard gold plating. Many people think that it can be used interchangeably for hard gold plating. It is a rubbish idea altogether because both offer different properties. Both techniques cannot replace one another. On the other hand, choosing the right service provider in terms of PCB manufacturing and plating is also necessary.

Comments are closed