In an ever-changing industry, one thing that must not be static is versatility or the ability to adapt to newer trends. When it comes to the Printed Circuit Board (PCB) industry, it is important for the manufacturing company or service provider to continually adapt to latest trends, as that would help it remain relevant in the market.

Such explains the moves by Nan Ya PCB, one of the leading suppliers and manufacturers of Printed Circuit Boards (PCBs) in Taiwan.

But Nan Ya PCB wasn’t originally into PCB production. The company is an offshoot of the broader Nan Ya Plastics Corporation, which focused on the production of plastics and related products.

Nan Ya Plastics Corporation, in turn, is a part of the broader Formosa Plastics Group. Seeing the opportunity in the Printed Circuit Board (PCB0 market, Nan Ya PCB would later be carved out of the corporation to be a standalone company overseeing the group’s interests in the PCB and IC substrates market.

Thus, that is how Nan Ya PCB became the PCB arm of the Formosa Plastics Group – and has continued to expand the base many years after.

The Focal Point

The core area of focus for Nan Ya PCB is in the production and sales of Printed Circuit Boards (PCBs). The company also offers a similar service for the Integrated Circuit (IC) substrates.

Nan Ya PCB’s Goals

The goals of the company are also in line with the core beliefs of the founders of the Formosa Plastics Group. These beliefs have to do with the commitment to ensuring that the products are not only of good standards, but are also optimized for the best possible results for the users.

It is in line with that mandate that Nan Ya PCB takes extra care to ensure that the PCBs and IC substrates it produces and sells are of the utmost performance.

PCB Capabilities

Let us start by analyzing the capabilities of Nan Ya PCB, in terms of Printed Circuit Boards (PCBs). These are some of the capabilities in the market:

1. Multi-Structured PCB Designs

Nan Ya PCB specializes in manufacturing different types of PCB structures or types. The three (3) major PCB structures it produces are the High Density Interconnect PCB (HDI PCB), Conventional PCB and the Rigid-Flexible PCB.

PCB Features

We must mention that just as Nan Ya PCB focuses on only a few PCB structure designs, the company also has limited capabilities, in terms of the features it incorporates into these circuit boards.

For example, the conventional or traditional PCBs can only boast of electrical connection.

When it comes to the Rigid-Flexible PCBs, the features cut across flexibility, electrical connection and build-up technology.

The High Density Interconnect PCB (HDI PCB) appears to have more features than the others, as it supports high-speed transition and electrical connection. It also supports high circuit density and the ability to stand up to signal disturbances.

PCB Conversion

According to the information on the website, Nan Ya PCB has the capability to facilitate the conversion of the PCB’s active and passive substrates into the Integrated Circuit (IC). This can be easily achieved by layout arrangement.

PCB Applications

The applications or use cases of the Printed Circuit Boards (PCBs) manufactured by Nan Ya PCB are commonly for the electronics we use every day.

For example, the HDI PCBs are typically used with MP3 players, smartphones, automobile appliances, game consoles, PDAs and GPS.

For the Conventional or traditional PCBs, the use cases cover the following: home electrical appliances, motherboards for both notebooks and desktops.

The typical applications of the Rigid-Flexible PCBs are notebooks and high-end portable devices.

2. IC Substrate Capabilities

In addition to manufacturing and selling Printed Circuit Boards (PCBs), Nan Ya PCB also makes the substrates for the Integrated Circuits (ICs).

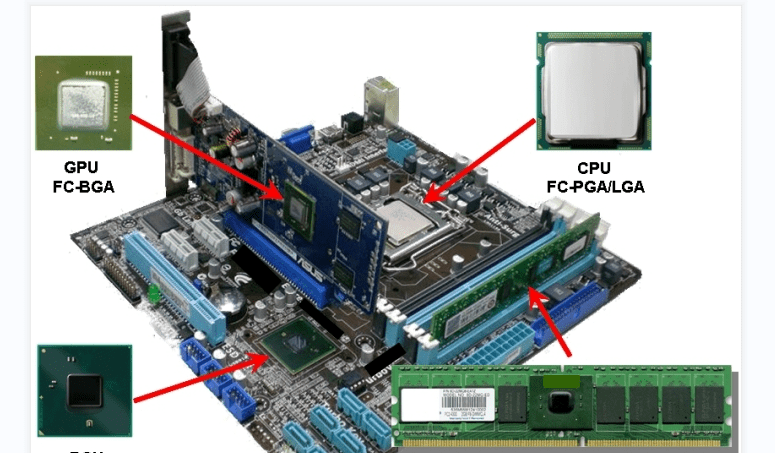

It must be mentioned that these IC substrates are further broken down into different categories, such as Wire Bond substrates and Flip Chip substrates.

Flip Chip Substrate Capabilities

This is the first type of IC substrates that Nan Ya PCB manufactures. The Flip Chip IC substrate takes the form of a die that is attached to the substrate. Among many other functions, it helps to serve as a connection between the Printed Circuit Board (PCB) and the chip.

For the connection to be established, solder bumps must be used instead of gold wires.

Types of Flip Chip Substrates

The common types of Flip Chip IC substrates manufactured by Nan Ya PCB are the:

- Ball Grid Array (BGA)

- Pin Grid Array (PGA) and;

- Land Grid Array (LGA).

The general applications of the substrates differ by the type of IC substrate. For example, the duo of LGA and PGA are applied to microprocessors, while the BGA is commonly used with the following:

- Set-top box chipsets

- Graphic microprocessors

- High-end ASIC chipsets and the;

- Northbridge chipsets

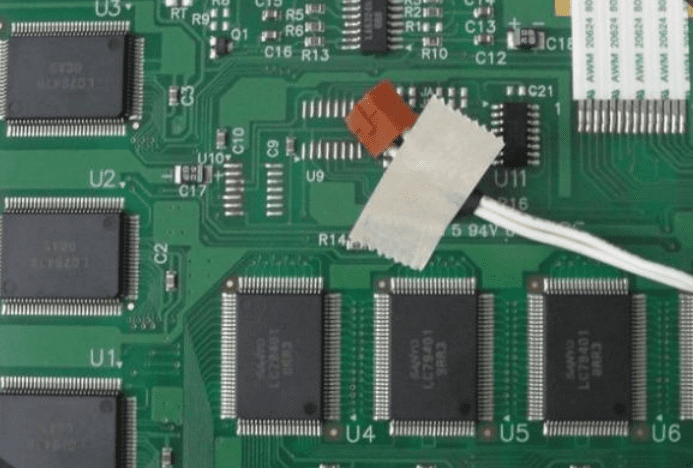

3. Wire Bond Substrates

These are the type of IC substrates made by using gold wires to connect the electrical pads and the chip from the substrate.

The major function of the Wire Bond substrate is to serve as a buffer between the Printed Circuit Board (PCB) and the chip.

Wire Bond Substrate Packages

There are two (2) major types or categories of Wire Bond substrates. These are the Ball Grid Array (BGA) and the Chip Scale Package (CSP).

For the BGA, the Plastic Ball Grid Array (PBGA) is the major classification.

When it comes to classifying the Chip Scale Package (CSP), it is further broken down into the following:

- Window BGA

- Wire Bonding CSP

- Flip Chip CSP or FC-CSP

Unlike the Flip Chip IC substrate, the Wire Bond IC substrates have more use cases or applications. These include PC Peripheral Device, Memory, such as Flash and DRAM, as well as consumer electronics. The applications also include portable devices and headsets. Those are for the Chip Scale Package (CSP).

For the Ball Grid Array (BGA), the core applications are with the networking devices, MCPs, communication devices and the Southbridge chipsets.

Final Words

Nan Ya PCB makes the job of designing and distributing Printed Circuit Boards (PCBs), Integrated Circuits (ICs) and IC substrates easier. With a well-thought-out mission statement and an extensive global presence, especially in the USA, Taiwan and China, the company just makes PCB and IC development simpler.

Comments are closed