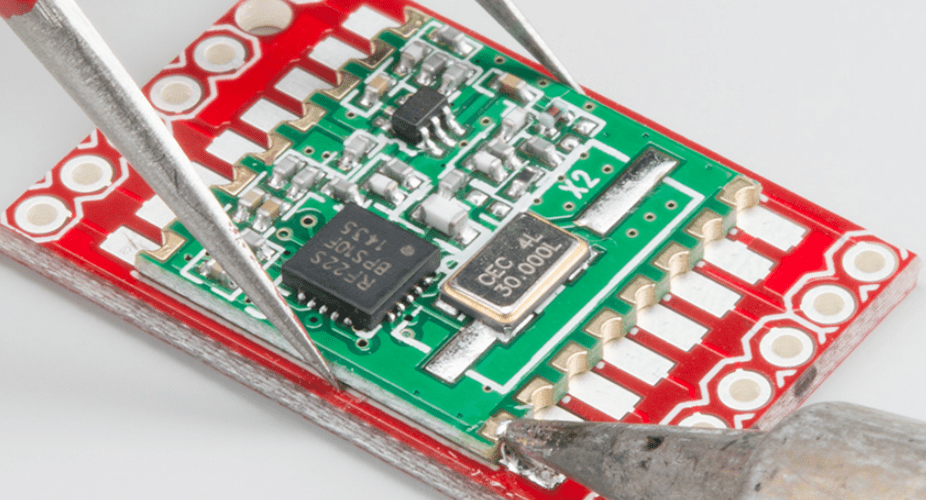

Generally, there are two forms of technology used when assembling PCBs. These forms are surface mount (SMT) and through-hole (THT). However, in recent years, a third and easier option is coming to the fore among board manufacturers, called board-to-board soldering. This technique is preferred when part of the assembly involves mounting a single module board on top of another.

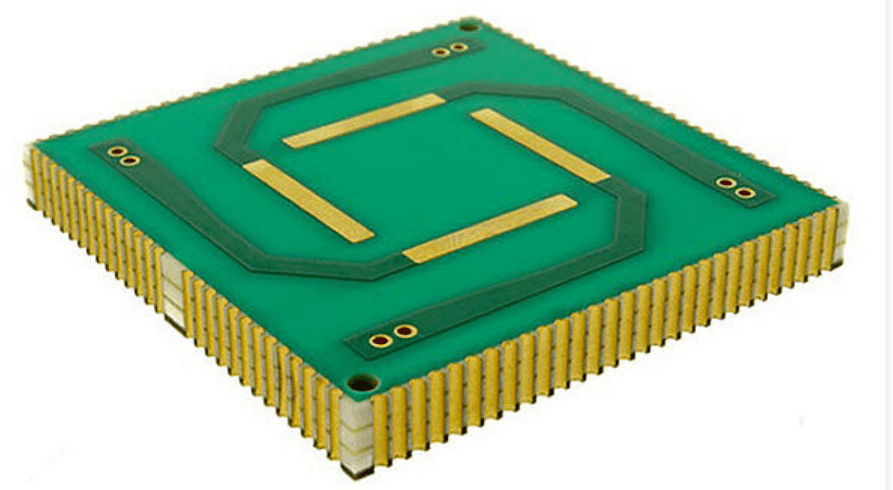

To do this, the manufacturer would have to “castellate” the PCB; hence the name castellated PCB. This is becoming much more common in printed circuit board manufacturing as the demand for PCBs keeps soaring.

This article will help you learn castellated PCBs’ importance and usefulness in the industry. It also provides relevant details that will help you understand how it works. Keep on reading to have a good understanding of castellated PCBs in PCB manufacturing.

What Are Castellated Holes?

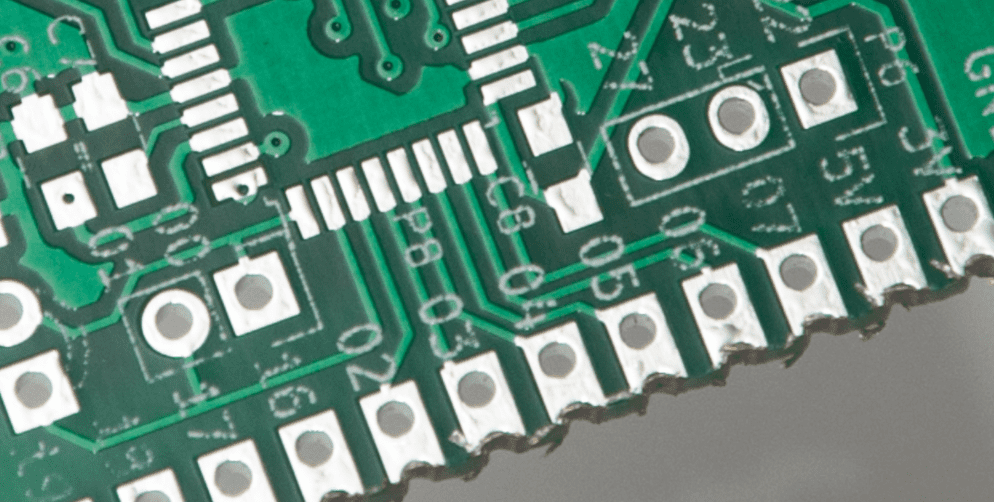

Castellations on a PCB, also called crenellations, plated half holes, or castellations, are through holes on a PCB that are cut and plated holes with specific dimensions. Their main use is to help create spaces on the edges of boards through which another board can be soldered onto the main board. Only when PCBs are castellated can they be joined with another board. However, all of these require preciseness and specificity.

Castellated PCBs make PCB board mounting and joining much easier. These holes act as a link-in between the module and the board when there is a need to solder on the module. The specified design of these holes – which make PCBs look more like cartoon cheese with incomplete, broken circles at the edges – offers the best alignment between boards during soldering and joining in the manufacturing process.

Creating castellations or plated holes is done for different PCB modules, such as Bluetooth or Wi-Fi. Each module is used as an independent part mounted on a separate board during PCB manufacturing and assembly. Surface Mount Technology and Through Hole Technology are the usual processes utilized during PCB assembly, but only when mounting boards are needed.

Why Castellated PCBs – Are They the Best Option?

Creating plated through holes on board edges helps manufacturers and designers replicate specific parts of a printed circuit board in a circuit. An example is when a circuit design includes inverters or feedback loops. These smaller sub-circuits can be produced en masse, tested, and soldered onto the mother PCB, which houses other parts of the circuit.

Below are other uses of castellated holes asides those discussed above:

- They can function as breakout boards for a specific part of the bigger PCB.

- Castellations allow for ease when changing the pin layout as required by the user.

- Integrated modules can be manufactured on a PCB board with a castellation. This can also be used in another assembly during manufacture.

- Castellated PCBs allow for easier mounting to a smaller PCB during the final manufacturing process.

- Castellated PCBs aid the combination of boards by validating the quality of the solder joint.

- Castellated holes help designers create wireless PCB links.

The Available Designs for Castellated PCBs

Different designs are available for castellated PCBs, and you must know what all these designs represent before settling for one. Some of the notable designs you may discover are listed below:

- Half Holes

- Mounting holes have smaller half-holes.

- Holes tangent to the edge of the board.

Where Are Castellated PCBs Used?

Below are some of the numerous industries that use Castellated PCBs:

- Power

- Computer applications (hardware)

- Automobiles

- Consumer electronics

- Industrial Control

- Telecommunication

Recommended Specifications for Castellated PCBs

Certain design factors need to be met in castellated PCB design, depending on the final function and what it is to be used for:

● Size

In castellated PCB design, it is advised to use the largest possible size. This will help designers mount the PCB correctly.

● Pad design

It is recommended to use the biggest possible pad above and below. This also allows for easier mounting.

● Number of holes

This depends on the design, but it is common knowledge that a smaller number of available holes will result in a more difficult PCB assembly process.

● Hole diameter and distance

Half holes are recommended for use in standard and advanced circuit boards. The minimum diameter for the holes in a standard circuit board is 0.6mm. However, the castellated holes are advised to be smaller than this figure for advanced circuit boards. Finally, the minimum distance between plated through holes on a PCB is 0.55mm.

● Surface finish

This is very important when it comes to PCB mounting. While the application or use of the PCB determines the type of surface finish, ENIG is generally the most acceptable surface finish for PCBs.

Things to Note When Designing Castellated PCBs

A castellated board must be of high quality and yield after production. The process of castellated PCB design entails designing pads with castellations. However, this process is an intricate one. Any mistake is termed costly as it could influence the performance of your PCB.

When designing a half-hole PCB, the designer should be aware of some key factors, and they are listed below:

● Use the top and bottom edges when locating the hole

The first thing to note is that it is important to ignore the vertical edges while making the holes. This is because the edges typically function as bridges and are as important as every other part of the board. This ensures that the PCB board is always bridging.

While there are numerous designs for half holes, they vary in number due to software.

● Holes with smaller lead-in holes

The castellations are ideal for any connector application and use. They also require a cutting tool or equipment to help create smaller holes where needed.

Conclusion

Castellated holes on PCBs are a very useful invention and offer various benefits. Knowing their benefits will help you channel your manufacturing prowess in the best direction for maximum profit and reduced process times when mounting and soldering. Also, producing durable castellated PCBs entails ensuring that the board is capable of withstanding mechanical stress, which will assist in preventing delamination and related faults during production and assembly.

Comments are closed