PCBs, or printed circuit boards, are the backbone of most modern electronics. These PCBs are composed of many delicate parts. You need to plan, manufacture, and assemble these parts to achieve the intended result. Thus, High Quality PCB Prototype assembly is a simple but time-consuming operation.

High Quality PCB Prototype manufacturing and assembly services necessitate years of training and practice. It’s not easy to achieve Zero defects on such a challenging task. Every PCB Assembly Services Provider Organization is not dependable.

It cannot be easy to choose the Best PCB Manufacturer or PCB Assembly Services Provider due to the abundance of options. Here, you will learn about the best PCB Prototype Manufacturers.

Is There Any Advantage of High Quality PCB Prototype for Small Businesses?

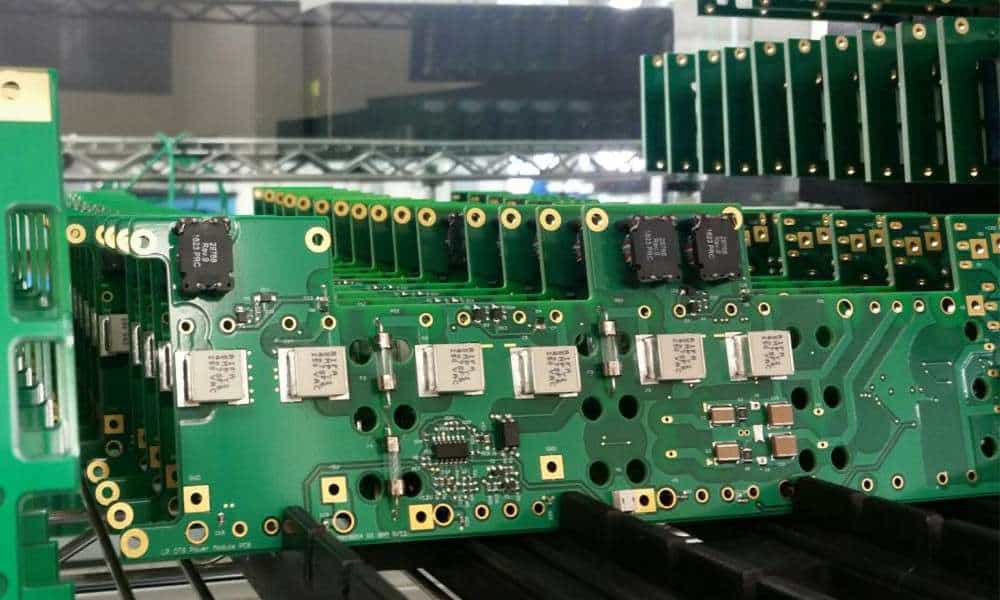

When it comes to saving money, this is crucial for startups and developers without deep pockets. The quality and terms are more than satisfactory, but the delivery time is a problem. You may find an excellent example in China, which they installed on industrial railroads.

It goes without saying that you can hire a service to make “prototypes” in a few days. But you still have to pay for the production preparation; in reality, this is an emergency order, and if you need to adjust the fee, no matter how modest, you’ll have to pay again for preparation.

The situation becomes considerably more problematic if you also need a PCB installation service, as this only pertains to boards. There is no such thing as a fast installation; the process is lengthy, costly, and necessitates extensive involvement from the customer in the nitty-gritty of production.

Why is a High Quality PCB Prototype Necessary?

It’s common to use the term “prototype” to refer to both the first model and the finalized product, yet, there is a significant difference between them.

In the early stages of product development, when engineers are still figuring out how to make their product, they produce prototypes to test out potential solutions.

This stage of the design process is highly experimental. It is not uncommon for several iterations of the design to get generated until you find the optimal configuration that satisfies the design requirements.

After ensuring that the prototype fully satisfies all design requirements, you can fine-tune the design for mass production. In this stage of the design process, product development, you’ll work on perfecting the prototype before sending it to manufacturing.

You need to make adjustments to facilitate manufacturing and improve product performance and longevity. However, prototype development is crucial to a project’s success because product development is on the prototype.

Steps Involved in High Quality PCB Prototype Manufacturing

- Step#1: Design and Output

- Step#2: From File to Film

- Step#3: Inner Layers Printing

- Step#4: Removing the Unwanted Copper

- Step#5: Optical Inspection and Layer Alignment

- Step#6: Layer-up and Bond

- Step#7: Drill

- Step#8: Plating and Copper Deposition

- Step#9: Outer Layer Imaging

- Step#10: Plating

- Step#11: Final Etching

- Step#12: Solder Mask Application

- Step#13: Surface Finish

- Step#14: Silkscreen

- Step#15: Electrical Test

- Step#16: Profiling and V-Scoring

The Best Companies for High Quality PCB Prototype Manufacturing and Assembly Services

It takes a lot of effort the production of printed circuit boards. It would be best if you chose a Manufacturer with a high degree of knowledge and a focus on quality at each stage.

Doing so will ensure that your PCBs are of expected quality, performance, and durability standards. Here are some of the Top-Rated Companies that you should opt for:

1. Rayming PCB & ASSEMBLY

Website: https://www.raypcb.com/

High Quality PCB Prototypes are available from RaYMing Technology, a world leader in PCB manufacturing and assembly.

RаYMing Tесhnоlоgу is an expert at providing companies of all sizes throughout the world with high-quality printed circuit board fabrication, PCB assembly, and components. Services sourced from firms with at least ten years of experience in the electronics manufacturing sector.

Aside from that, they also offer their services on more luxurious vessels. Different types of printed circuit boards (PCBs) include flex-rigid PCBs, Teflon PCBs, HDI boards, aluminum PCBs, and high-frequency circuit boards.

2. Hillaman Curtis

Website: https://hillmancurtis.com/

Hillaman Curtis ensures that it works on even the smallest of manufacturing details. Their sole concern is ensuring that every one of their customers is happy with the service they receive.

From a complex multi-layer board to a double-sided surface mount design, they aim to supply high-quality items that match the needs of our customers in the most economical way possible.

Experience with IPC Class III standards, stringent clean-line requirements, heavy copper, and tight production tolerances allow them to give our customers and us exactly what we need. Hillaman Curtis is the premier PCB manufacturing assembly service because of the genuine dedication of its employees and the unmatched technical expertise of its team.

3. Advanced Circuitry International (ACI)

ACI is a leading global provider of RF, Microwave, and Antenna Printed Circuit Boards. This firm operates factories in Atlanta, Curitiba, and Gandhinagar, all inside Georgia.

When it comes to printed circuit boards (PCBs) for use in industries including aerospace, defense, telecommunications, and medical devices, ACI is unrivaled in the United States. Their specialty is Rapid Prototyping, Antenna, Multilayer PCBs, Large Format, and PCB Assembly Services.

4. Epec Engineered Technologies

The headquarters of Epec Engineered Technologies may be found in Massachusetts, although the pcb assembly company has offices and representatives across the Americas, Asia, and Western Europe.

OEMs can get individualized PCB solutions from them. They guarantee the most efficient, timely, and economical design and production method.

Epec Engineered Technologies specializes in designing and producing highly dependable electronics for various applications, including medical devices, test and measurement equipment, electronics for the military and aerospace industries, portable and consumer electronics, industrial applications, and the automotive and transportation sectors.

5. NexLogic

You may find the headquarters of NexLogic in Sunnyvale, California. They offer low-priced printed circuit board design, fabrication, assembly, and testing services. Pb-Free PCB assembly is a specialty of their firm, and they provide a comprehensive service.

The medical, defense, semiconductor, telecommunications, commercial, and oceanographic sectors are just some of the many users of their high-quality PCBs and PCB Assemblies.

6. TechnoTronix

You can find the headquarters of Technotronix in sunny California. This firm caters to its client’s specific needs by providing PCB prototyping, assembly, and manufacturing.

Aerospace, defense, wireless telecommunications, medicine, renewable and solar energy, and rigid-flex PCB technology are just a few fields that use their world-class printed circuit boards and printed circuit board assemblies.

7. Journey Circuits Inc

Journey Circuits, with headquarters in Illinois, is among the most prominent and extensive American PCB producers. Stencils, Printed Circuit Boards, and PCBs are all things they deal with.

Their Printed Circuit Boards and Assemblies are in the Communications, Industrial, Medical Equipment, Aerospace, Automotive, Computer, Power, and Instrumental Industries because of their dependability, high quality, and affordability.

8. VSE

For over 30 years, VSE has been a leading low-volume, high-mix PCB maker focusing on producing prototype and mass-produced circuit boards.

One of their claims to fame is that they can take a napkin sketch and turn it into a completely constructed and tested product thanks to their ability to work with many forms of engineering input to build a functional prototype.Website:

9. Custom Circuit Boards

Located in sunny Phoenix, Arizona, Custom Circuit Boards is a one-stop shop for your Printed Circuit Board fabrication needs, from prototype to mass production.

As part of their skillset, they can manufacture printed circuit boards with anywhere from one to forty layers. It will meet your needs and designs and can accommodate low-, medium-, and high-volume production without breaking the bank. :

10. RedBoard Circuits, LLC

You can find the headquarters of Redboard Circuits in Arizona. All their printed circuit boards are compliant with RoHS and are in Taiwan or China. They’re a significant player in the North American printed circuit board industry.

RedBoard Circuits LogoPCB is a maker of various PCB types for use in various fields. Some of their abilities are:

- Single Sided PCB

- Castellated Holes and Countersink

- Double Sided PCB

- RF and Microwave

- Rigid-Flex PCB

- Multi-layers PCB

- Flex PCB

- Aluminum and Metal Core

- HDI :

Considerations that you need to Make When Choosing a High Quality PCB Prototype

Your new product’s market acceptance will be made or broken during the prototype stage. Rapid and accurate prototyping is essential, as is its subsequent incorporation into product design and mass production.

If you want your prototype builds to go smoothly, you need to find a reliable PCB contract manufacturer. Here are some things to keep an eye out for when you search for the best contract manufacturer to handle the construction of your prototype:

Consideration#1: Location

Prototyping a printed circuit board, or PCB can be a time-consuming process. The prototype will likely undergo revisions due to your continued engineering of the project or due to design evaluations by the CM.

It can do the task remotely, but it will go more smoothly if you have a local CM. Not only will you be on the same schedule as the CM, but you’ll also have the option of hosting CM employees at your office.

Consideration#2: Capabilities

If you’re looking for a CM, one specializing in prototyping is a good indicator that they can handle low-volume, high-mix production.

It allows them to be more adaptable to your needs and to switch gears from one project to another more quickly and efficiently than huge manufacturers. To learn more about their expertise, you could contact their previous clients for references and read any reviews they may have left.

Consideration#3: Assurance of Quality

To what extent does the CM you plan to deal with have a quality control system that meets ISO 13485 and ISO 9001? Your products’ compliance with these standards must be verifiable.

Thus the CM you’re working with must be well-versed in them. The CM must also employ automatic and manual inspection systems at various points in the production cycle to guarantee the highest quality standards.

Consideration#4: Box Build Capabilities

It is highly advantageous to work with a PCB CM that can construct the circuit board and the box, cable assemblies, and wire harnesses for the entire system.

Not only will you have to deal with one manufacturer instead of a number of them, but the CM will also be able to design and construct the entire prototype system to be compatible with one another.

Consideration#5: Documentation

Your prototype’s form factor, bill of materials (BOM), and circuitry will likely go through numerous revisions as you build it.

Your CM should be able to take your raw data, clean it up, and re-generate it in a format that you can readily import into your existing documentation infrastructure.

It will give you command over future board modifications, and you can quickly and efficiently take the design into mass production when correct.

Consideration#6: Supply Network for Parts

You should plan on making adjustments to the components on your prototype PCB due to changes in the circuitry, DFM requirements, or the cost and availability of the individual parts.

You should look for a CM that employs a team of component engineers and buyers well-versed in supply chain logistics. To make sure your prototype is assembled on time and within budget, they should also have a well-established network of component manufacturers and distributors to work with.

Consideration#7: Certification

Do employees at the CM under review tend to be upbeat and helpful toward one another and their clients? A CM’s first reaction to you might tell you a lot about them.

Were they eager to have you come in, show you around, and explain what they could do for you? Is the staff up-to-date on industry practices and qualified to perform at the required level?

Conclusion

Finding a High Quality PCB Prototype Manufacturer is one of the most straightforward tasks. However, people miss some critical considerations when choosing a PCB prototype and end up in the worst situation.

The 10 top High Quality PCB Prototype Manufacturers mentioned in this article are the best to get quality work without any worries. Here, I conclude my article. I hope this article was of help to you. For more information, stay tuned!

Comments are closed