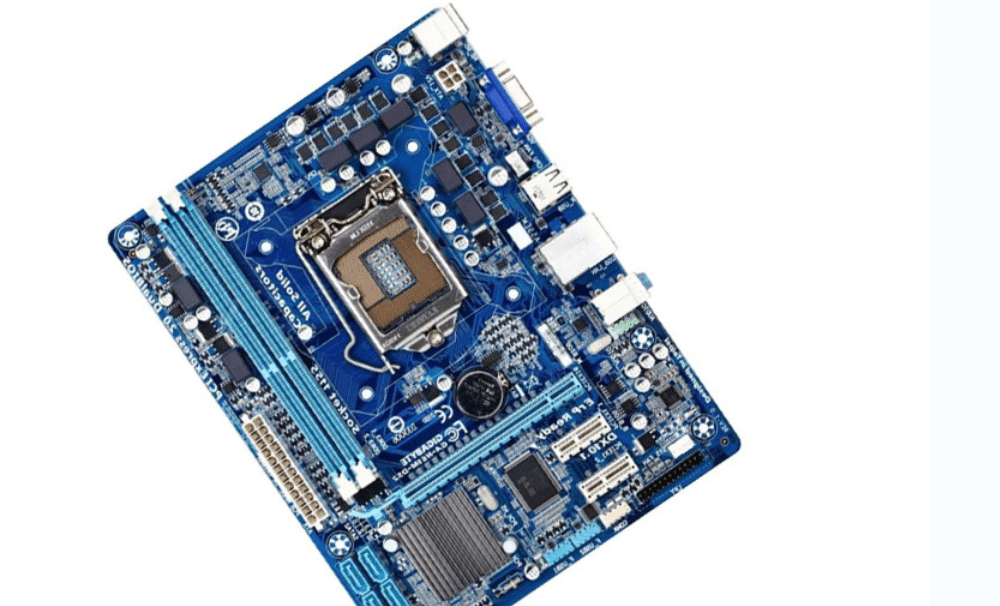

High-quality PCB (Printed Circuit Board) prototypes are essential for any electronic product development process. PCBs are the backbone of any electronic device, and their quality determines the reliability and performance of the final product. A high-quality PCB prototype ensures that the final product meets the required specifications and standards.

The PCB prototype process involves several stages, including design, fabrication, assembly, and testing. Each stage is critical to the success of the final product, and any errors or defects can result in costly delays and rework. Therefore, it is essential to work with a reputable PCB prototype manufacturer who has the expertise and experience to deliver high-quality prototypes that meet your specific requirements. With the right PCB prototype partner, you can ensure that your product development process is smooth and efficient, and your final product is reliable and performs as expected.

What is a PCB Prototype?

Definition

A PCB prototype is a sample or test version of a printed circuit board (PCB) that is created to verify the design and functionality of the final PCB. It is a crucial step in the PCB manufacturing process as it allows engineers and designers to test and refine their designs before mass production. PCB prototypes are typically produced in small quantities, and they are used for testing, debugging, and validating the circuit board design.

Importance

The importance of PCB prototypes cannot be overstated. They play a critical role in the PCB manufacturing process, helping to ensure that the final product meets the required specifications and standards. PCB prototypes allow designers and engineers to identify and correct design errors, optimize the circuit board layout, and test the functionality of the board before mass production.

By creating a PCB prototype, designers and engineers can test the board’s electrical performance, mechanical stability, and thermal behavior. They can also evaluate the board’s manufacturability, identify potential issues with the assembly process, and make any necessary adjustments to ensure that the final product is of the highest quality.

In summary, PCB prototypes are an essential part of the PCB manufacturing process. They allow designers and engineers to test and refine their designs, ensuring that the final product meets the required specifications and standards.

Factors to Consider in Creating High-Quality PCB Prototypes

When it comes to developing high-quality PCB prototypes, there are several factors that need to be considered. These include the design software, materials used, and the assembly process. In this section, we will explore each of these factors in more detail.

Design Software

The design software used to create the PCB prototype is critical to ensuring its quality. It is important to choose software that is reliable, easy to use, and has a wide range of features. Some popular design software options include Altium Designer, Eagle PCB, and KiCAD. These programs allow for easy component placement, routing, and error checking.

Materials

The materials used to create the PCB prototype also play a significant role in its quality. High-quality materials ensure that the prototype is durable and reliable. Common materials used in PCB prototypes include copper, FR-4, and solder mask. It is important to choose materials that are compatible with the design software being used and that meet the required specifications.

Assembly Process

The assembly process is another critical factor in creating high-quality PCB prototypes. The assembly process involves soldering components onto the PCB board. It is important to use a high-quality soldering iron and to follow the correct procedures to ensure that the components are properly secured. Additionally, it is important to test the prototype thoroughly before finalizing it.

In conclusion, creating high-quality PCB prototypes requires careful consideration of several factors, including the design software, materials used, and assembly process. By taking these factors into account and following best practices, it is possible to create PCB prototypes that are reliable, durable, and of high quality.

Benefits of High-Quality PCB Prototypes

When designing a printed circuit board (PCB), it is essential to use high-quality prototypes. Here are some benefits of using high-quality PCB prototypes.

Cost Savings

High-quality PCB prototypes can save you money in the long run. They are less likely to fail, which means you will not need to spend money on repairs or replacements. Additionally, high-quality PCB prototypes are less likely to cause damage to other components, which can also save you money.

Improved Functionality

High-quality PCB prototypes can improve the functionality of your product. They are designed to be more efficient and reliable, which can lead to better performance. Additionally, high-quality PCB prototypes can be customized to meet specific needs, which can improve the overall functionality of your product.

Reduced Time to Market

High-quality PCB prototypes can help reduce the time it takes to bring your product to market. They are designed to be more efficient and reliable, which can lead to faster production times. Additionally, high-quality PCB prototypes can be customized to meet specific needs, which can help speed up the design process.

In conclusion, using high-quality PCB prototypes can provide many benefits, including cost savings, improved functionality, and reduced time to market. By investing in high-quality PCB prototypes, you can ensure that your product is reliable, efficient, and of the highest quality.

Challenges in Creating High-Quality PCB Prototypes

Complexity

One of the biggest challenges in creating high-quality PCB prototypes is managing their complexity. PCBs can have hundreds or even thousands of components, and ensuring that each component is placed correctly and connected properly can be a daunting task. As PCBs become more complex, the risk of errors and defects increases, which can lead to costly delays and rework.

Quality Control

Another challenge in creating high-quality PCB prototypes is maintaining consistent quality control throughout the entire production process. Quality control measures must be in place at each step of the process, from design and layout to manufacturing and assembly. Any deviation from the established quality standards can result in defects, which can lead to product failures and customer dissatisfaction.

To ensure that quality control is maintained, PCB manufacturers must invest in advanced equipment and software that can detect defects and errors early in the production process. This can include automated optical inspection (AOI) systems, X-ray inspection, and other advanced testing equipment.

Testing

Finally, testing is a critical component of creating high-quality PCB prototypes. Testing must be performed at each stage of the production process to ensure that the PCB meets the required specifications and standards. This can include electrical testing, functional testing, and environmental testing.

Electrical testing involves verifying that each component is functioning correctly and that all connections are properly made. Functional testing involves verifying that the PCB is performing as intended and that all features and functions are working correctly. Environmental testing involves subjecting the PCB to various environmental conditions, such as temperature and humidity, to ensure that it can withstand harsh operating conditions.

In conclusion, creating high-quality PCB prototypes is a complex process that requires careful attention to detail and a commitment to quality control and testing. By investing in advanced equipment and software and implementing rigorous quality control measures, PCB manufacturers can ensure that their products meet the highest standards of quality and reliability.

Conclusion

In conclusion, obtaining high-quality PCB prototypes is crucial for the success of any electronics project. The quality of the PCB prototype plays a significant role in determining the reliability and performance of the final product. Therefore, it is essential to choose a reputable and experienced PCB manufacturer to ensure that the prototypes meet the required standards.

When selecting a PCB manufacturer, consider factors such as their experience, reputation, and the quality of their equipment. It is also important to ensure that the manufacturer uses high-quality materials, such as copper and solder mask, to produce the prototypes. Additionally, the manufacturer should have a robust quality control process to ensure that the prototypes meet the required specifications.

Overall, investing in high-quality PCB prototypes is an investment in the success of your electronics project. By working with a reputable and experienced PCB manufacturer, you can ensure that your prototypes meet the required standards and are reliable and high-performing.

Comments are closed