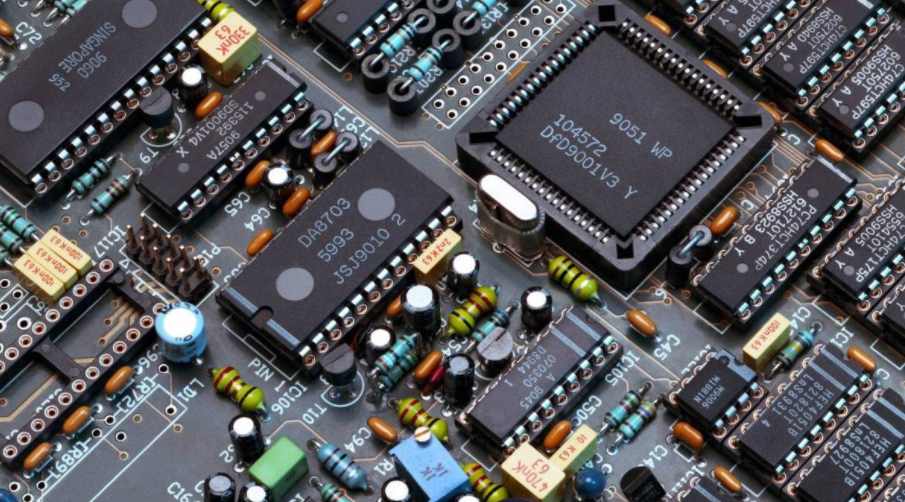

Prototype PCBs are an essential component of the electronics industry. They allow engineers to test and refine their designs before committing to a full production run. Getting an accurate quote for a prototype PCB is crucial for any project, as it can impact the overall cost and timeline of the development process.

When it comes to getting a prototype PCB quote, there are several factors to consider. The size, complexity, and quantity of the boards all play a role in determining the final cost. Additionally, the materials used and the turnaround time required can also affect the price. It’s important to work with a reputable PCB manufacturer who can provide accurate quotes and deliver high-quality boards on time.

What is a Prototype PCB Quote?

A prototype PCB quote is a detailed estimate of the cost of producing a small quantity of printed circuit boards (PCBs) for testing and validation purposes. PCBs are essential components in electronic devices, and a prototype PCB quote provides an estimate of the cost of producing a small batch of PCBs before full-scale production.

The prototype PCB quote typically includes the following details:

- The number of PCBs required

- The size and shape of the PCBs

- The type of material used in the PCBs

- The number of layers in the PCBs

- The thickness of the copper traces

- The type of surface finish

- The delivery time

To get an accurate prototype PCB quote, it is important to provide the manufacturer with detailed information about the PCB design, including the number of layers, the size and shape of the board, and the type of components that will be used. This information will help the manufacturer to determine the most cost-effective way to produce the PCBs.

In addition to providing an estimate of the cost of producing the PCBs, the prototype PCB quote may also include recommendations for optimizing the design for manufacturability, such as changes to the layout or the use of different materials. This can help to reduce the cost and time required for full-scale production.

Overall, a prototype PCB quote is an essential tool for electronics manufacturers and designers, providing a detailed estimate of the cost of producing a small batch of PCBs for testing and validation purposes.

Factors Affecting Prototype PCB Quote

When it comes to prototyping printed circuit boards (PCBs), several factors can affect the quote you receive from a manufacturer. Here are some of the most important factors to keep in mind:

Design Complexity

The more complex your PCB design, the higher the quote you can expect to receive. This is because complex designs require more time and effort to manufacture, test, and assemble. Some examples of design complexity include:

- High-density interconnect (HDI) boards

- Multi-board designs

- Designs with many components or connectors

- Designs with unusual shapes or cutouts

Number of Layers

The number of layers in your PCB also affects the quote. More layers mean more materials and manufacturing steps, which can increase the cost. However, adding more layers can also improve the performance and functionality of your PCB. Some common layer counts include:

- 2-layer (single-sided)

- 4-layer

- 6-layer

- 8-layer

- 10-layer or more

Board Size

Larger PCBs require more materials and manufacturing time, which can increase the quote. However, larger boards can also offer more space for components and features. Some common board sizes include:

- 2″ x 2″ (50mm x 50mm)

- 4″ x 4″ (100mm x 100mm)

- 6″ x 6″ (150mm x 150mm)

- 8″ x 8″ (200mm x 200mm)

- 12″ x 12″ (300mm x 300mm) or larger

Material Type

The type of material you choose for your PCB can also affect the quote. Some materials are more expensive than others, and some offer better performance or durability. Common materials include:

- FR-4 (fiberglass-reinforced epoxy)

- Rogers (high-frequency laminates)

- Aluminum (metal-core PCBs)

- Flexible materials (polyimide or polyester films)

Turnaround Time

Finally, the turnaround time you need for your PCB can also affect the quote. Rush orders or expedited shipping will increase the cost, while longer lead times may be more affordable. Some common turnaround times include:

- Standard (1-2 weeks)

- Expedited (3-5 days)

- Same-day or next-day (24-48 hours)

Overall, understanding these factors can help you plan and budget for your prototype PCB project. By working with a reputable manufacturer and providing clear specifications, you can get an accurate quote and ensure a successful outcome.

How to Get a Prototype PCB Quote

Choosing a PCB Manufacturer

When choosing a PCB manufacturer for your prototype, it’s important to consider a few key factors. First, you’ll want to look for a manufacturer with a good reputation for quality and reliability. You can do this by reading reviews and checking their certifications and accreditations.

Next, consider the manufacturer’s capabilities and services. Do they offer the specific type of PCB you need? Do they have the equipment and expertise to handle your project? Also, pay attention to their turnaround time and pricing.

Submitting Your PCB Design Files

Once you’ve chosen a manufacturer, you’ll need to submit your PCB design files. Make sure your files are in the correct format and that they meet the manufacturer’s requirements. You may also need to provide additional information, such as the quantity of PCBs you need and any special requirements.

Getting a Quote

After submitting your design files, you’ll receive a quote from the manufacturer. This quote will include the cost of the PCBs, as well as any additional fees for setup, testing, and shipping. Make sure to review the quote carefully and ask any questions you may have before placing your order.

In some cases, you may be able to request a quote online using the manufacturer’s quote tool. This can be a convenient option if you’re short on time or prefer to handle things digitally.

Overall, getting a prototype PCB quote can be a straightforward process if you choose the right manufacturer and provide accurate design files. By following these steps, you can ensure that you get an accurate quote and high-quality PCBs for your project.

Comparing Prototype PCB Quotes

When it comes to choosing a PCB manufacturer for your prototype project, comparing quotes from different manufacturers can be a daunting task. In this section, we will discuss the key factors to consider when comparing prototype PCB quotes.

Price Comparison

Price is often the first factor that comes to mind when comparing PCB quotes. However, it’s important to remember that the lowest price doesn’t always mean the best value. Some manufacturers may offer lower prices but cut corners on quality or have longer lead times. When comparing prices, look for manufacturers with transparent pricing and no hidden fees.

Lead Time Comparison

The lead time for your prototype PCB can be critical to your project’s success. Some manufacturers offer expedited services at an additional cost, while others may have longer lead times but lower prices. When comparing lead times, look for manufacturers that can meet your project’s timeline without compromising quality.

Quality Comparison

The quality of your prototype PCB is crucial to ensuring your project’s success. When comparing quotes, look for manufacturers with a proven track record of producing high-quality PCBs. Consider factors such as the manufacturer’s certifications, testing procedures, and customer reviews.

In conclusion, comparing prototype PCB quotes requires careful consideration of price, lead time, and quality. By taking the time to compare quotes from different manufacturers, you can find the best value for your project’s needs.

Conclusion

In conclusion, obtaining a prototype PCB quote is an important step in the PCB manufacturing process. It allows you to estimate the cost of your project and make informed decisions about your budget.

When requesting a quote, it is important to provide accurate and detailed information about your project, including the number of layers, board size, and any special requirements. This will ensure that you receive an accurate quote and avoid any unexpected costs or delays in production.

It is also important to consider the quality and reliability of the PCB manufacturer when selecting a supplier. Look for a manufacturer with a proven track record of producing high-quality PCBs and providing excellent customer service.

Overall, obtaining a prototype PCB quote is a crucial step in the PCB manufacturing process that can help you save time and money in the long run. By working with a reputable manufacturer and providing accurate project details, you can ensure a successful and cost-effective production process.

Comments are closed