Do you want to manufacture multilayer ceramic PCB for your company or your clients? The first thing you must do is to find out the best ceramic PCB manufacturers because they are the ones to help you design the circuit board.

We understand that the selection process might be a bit daisy for you because you are not sure of the things to look for before deciding on the best PCB designer for the job.

First things first – we will like you to understand what ceramic PCB means. Understanding it goes a long way in helping you understand the technicalities of the design and the things to expect.

What Is Ceramic PCB?

You may have heard so much about ceramic circuit boards and how they are one of the best Printed Circuit Boards (PCBs) models out there. Yet, you haven’t fully understood how they make so much impact in the Printed Circuit Board (PCB) industry.

We will now clarify that by explaining what ceramic PCBs mean, and why circuit board consumers love to manufacture for their electronic devices and their clients as well.

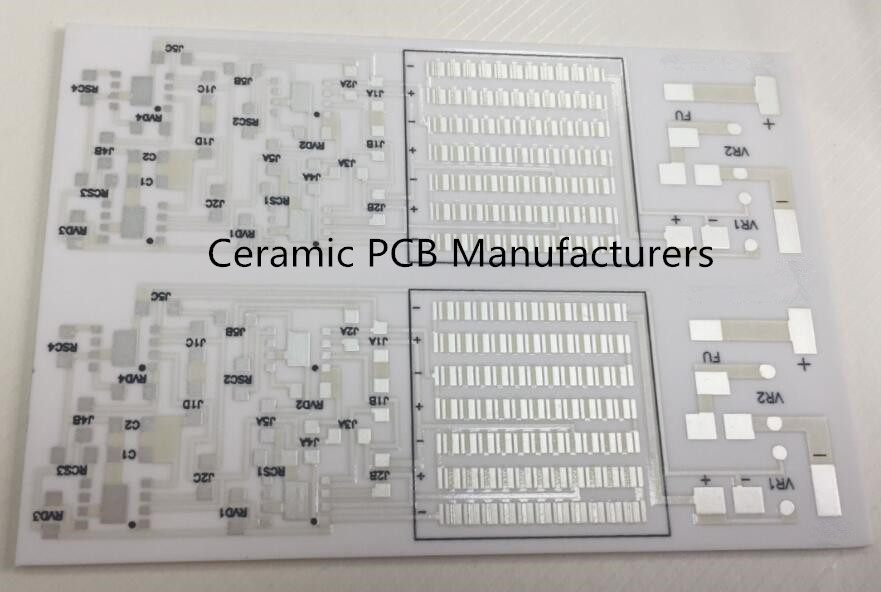

Ceramic PCBs are simply circuit boards that have ceramic base material. The material used for the base is usually thermal conductive and that is why ceramic circuit boards have a faster effect on the transfer of heat away from the hot spots.

The immediate transfer of heat leads to the protection of the hot spots while channeling the heat over the whole surface of the circuit board.

The Top 10 Organic Ceramic PCB Manufacturers

Manufacturing a ceramic circuit board takes time and effort. That is why you must select the best organic ceramic PCB manufacturer to help you design the circuit board.

1. Well-Tech PCB

Well-Tech PCB is one of the leading ceramic PCB manufacturers and you will be pleased with the conscious efforts they make to improve the design of the PCBs they manufacture for you.

This is one of the few manufacturers out there that have maintained quality and speed of delivery over the years. Since those are most of the important factors you consider, you are sure that they have what it takes to make your next ceramic PCB design look great.

Now, there is more to the manufacturing of circuit boards with ceramic base materials, and Well-Tech PCB is versed with all the technicalities involved.

Below are some of the reasons why every PCB consumer wants to hire the services of Well-Tech PCB for their next ceramic circuit board production:

PTFE Base Material

The base material of every Printed Circuit Board (PCB) matters a lot. In the case of the ceramic circuit board, ceramic base materials are used.

Worthy of note is that some PCB consumers and manufacturers alike may want to go the extra mile to pick out additional options to make the circuit board look better. That is the reason why Well-Tech does a swell job of using PTFE base material for most of the circuit boards they manufacture.

Strong Diversity

Diversification of materials helps to bolster the aesthetics of the circuit board. Well-Tech PCB does an excellent job in that regard by diversifying on the type of materials they use when manufacturing circuit boards.

They Use Ceramic Substrate

Well-Tech PCB uses a ceramic substrate, especially when they manufacture automotive LED circuit boards.

High Reliability

The reliability of the ceramic circuit boards manufactured by Well-Tech PCB is not in doubt because they guarantee you that the board will work as it ought to.

2. 6PCBA

6PCBA wants to make the task of manufacturing ceramic PCBs easier for you by providing you with a one-stop service. As one of the leading Printed Circuit Board (PCB) assemblers, the manufacturer keeps an eye on the overall design of the board.

Now, 6PCBA has evolved over the years to start offering a one-stop service that covers most aspects of ceramic substrate (ceramic PCB) production. With an excellent ordering process that provides you with an instant quote, you are confident that you wouldn’t waste further time to place an order for the circuit board.

Besides, they offer you an extensive manufacturing process that includes:

- Direct Plate Copper (DPC)

- High-Temperature Co-fired Ceramic (HTCC)

- Direct Bonded Copper (DBC) and

- Low-Temperature Co-fired Ceramic (LTCC)

3. Ray PCB

Rayming Technology (Ray PCB) has over the years grown to become one of the most sought-after ceramic PCB manufacturers in the world. Their quality circuit boards are not only outstanding but also provide the best service to PCB consumers.

Ray PCB offers you qualitative ceramic PCB manufacturing that comprises the use of the latest technology and cost-effective production.

Why You Should Let Ray PCB Manufacture Your Ceramic PCB

Ray PCB promises to offer you the best ceramic circuit board services if you hire them. The factors below will convince you as to why they are in a better position to deliver the type of designs you want for your next ceramic PCB projects:

Ceramic PCBs Designed with Hermetic Packages

While ceramic circuit boards offer better high-efficiency performance capabilities, more components can be included to improve the board further.

Ray PCB helps you out on that by integrating hermetic packages that prevent the circuit board from absorbing water. That also includes the expansion coefficient and enviable thermal properties that buoys the board to work in high-power applications of up to 350 degrees Celsius.

Increased Thermal Conductivity

You can ask the PCB manufacturer (Ray PCB in this case) to increase the thermal conductivity up to 406 W/mK. The implication is that silver will be used to line the printing traces while glass will be used to cover that for maximum protection from high operational temperatures.

Ray PCB Protects the Exposed Circuit Pads

Silver used in lining the printing traces may be subject to corrosion. You don’t want that to happen because it could undermine the efficiency of the ceramic circuit board.

Ray PCB once more saves the day by using gold plating to prevent the exposed circuit pads. That way, the exposed pads of your ceramic circuit board will not be eroded by silver corrosion, especially when they are deployed for use in high sulfur environments.

4. Best Technology

Best Technology has since established its brand as an authority as far as ceramic Printed Circuit Board (PCB) designs are concerned.

They primarily focus on the production of different types and variants of ceramic circuit boards. You want to hire a manufacturer that does not only focus on that area alone but also does exceedingly well.

With the use of innovative ceramic PCB manufacturing techniques, they have been able to distinguish themselves from other manufacturers that are generalized.

Their services include:

Engineering & Process Design

Best Technology comfortably handles everything about your ceramic PCB design from the engineering to the prototype and final production.

Full System Integration

This manufacturer also does an excellent job of providing you with a full system integration/full turnkey that takes off more of the workload from you.

Component Sourcing Solutions

If you are not disposed to source the components for your ceramic circuit board, you can always rely on Best Technology to help you.

With their complete component sourcing and management solutions, you will be on your way to taking deliveries of your completed ceramic Printed Circuit Boards (PCBs) after a few days.

Best Technology specializes in the manufacturing of the following types of ceramic PCBs:

- Quick turn ceramic circuit board

- China custom ceramic circuit board

- Fast ceramic Printed Circuit Board (PCB) design

- China turnkey ceramic PCB manufacturing and

- Custom ceramic Printed Circuit Board (PCB)

5. Rigid-Flex Tech

Rigid-Flex Tech (also called C-Flex) is not only a primary manufacturer of rigid-flexible circuit boards. They also specialize in the design and production of ceramic Printed Circuit Boards (PCBs).

They offer you a variety of circuit boards that are usable in different industries, especially in the communication sector.

Some of their ceramic base dielectric circuit boards include:

- Aluminum nitride ceramics Printed Circuit Boards (PCBs)

- Ceramic thick copper 2L circuit boards

- Aluminum oxide ceramics PCBs

- Aluminum nitride circuit boards

- Nitride aluminum PCBs

- Ceramic base Printed Circuit Boards (PCBs)

- Optical module circuit boards

- Thick copper ceramic circuit boards and

- Quantum transport circuit boards

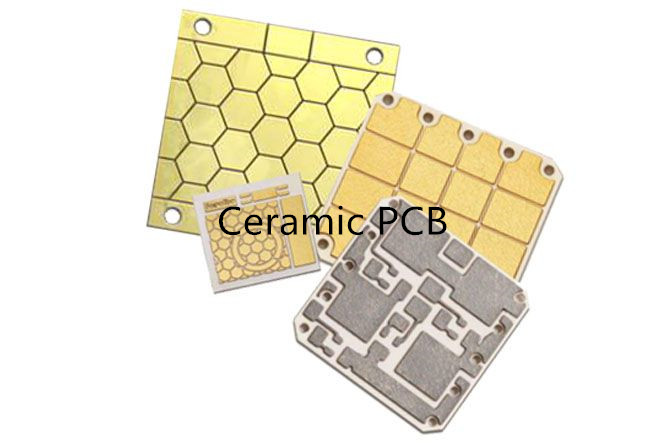

Types of Ceramic Printed Circuit Boards (PCBs)

This article is not yet complete if we don’t mention the different types of circuit boards that are manufactured with ceramic base materials.

So, below are the three main types of ceramic Printed Circuit Boards (PCBs):

1. Low-Temperature Ceramic Printed Circuit Boards (PCBs)

This type of ceramic circuit board is based on the classifications of the circuit board based on the manufacturing process.

This type of ceramic circuit board has a low temperature because of the less warpage and evolutionary shrink tolerance.

In addition, the low-temperature ceramic PCB is mostly used because of the higher thermal benefit that the board has to offer.

2. High-Temperature Ceramic PCB

The high-temperature ceramic Printed Circuit Board (PCB) is the type that uses advanced temperature to bolster the efficiency of the Printed Circuit Board (PCB).

The use of solvent mixed with raw ceramics, aluminum oxide, mixed adhesive, and plasticizer go a long way to improve the efficiency of the ceramic circuit board it is used on.

3. Thick Film

The primary aim of Thick Film ceramic PCB is to provide enough room for the incorporation of copper into the circuit board. Also, the incorporated copper will be further protected from oxidation when a thick film is added to the components of the ceramic circuit board.

Advantages of Ceramic PCB

There are several reasons why PCB consumers like to design circuit boards with ceramic base materials.

Here are some of the advantages and benefits you will derive from using ceramic Printed Circuit Boards (PCBs):

1. Multiple Layers Can Be Incorporated

There is no gainsaying the fact that layers play an important role in the formation of Printed Circuit Boards (PCBs). And for you to conveniently maximize all the benefits that the board has to offer, you have to add the right number of layers.

You needn’t worry about how to do that because the ceramic PCB does that via the multi-layering support that allows you to add or incorporate as many layers as possible into the circuit board.

It will interest you to know that the high mechanical strength of the circuit board makes it easier for the multi-layering support to contain as many layers as possible while handling complex tasks.

2. Excellent Heat Transfer

If there is any reason why PPCB consumers love ceramic circuit boards, it has to be because of the superior thermal conductivity that creates more room for excellent heat transfer.

You will agree that the presence of excess heat on a Printed Circuit Board (PCB) can lead to dysfunction.

However, when a superior thermal conductivity as offered by ceramic PCB is in place, it becomes easier to channel excess heat on the board to somewhere else.

Besides, ceramic circuit boards have specific components and materials that bolster the superiority of the board’s thermal conductivity/heat transfer. Some of those components are:

- Aluminum nitride

- Beryllium oxide and

- Aluminum oxide

3. Ceramic Circuit Boards are Manufactured with High-Quality Materials

The quality of materials used in the production of ceramic Printed Circuit Boards (PCBs) is also advantageous to the overall aesthetics of the board.

Nothing is spared when manufacturing the circuit board because ceramic PCB manufacturers use the best and high-quality materials because those are part of the reasons why the board functions excellently.

4. Ceramic PCBs Work Well Under Pressure

The other benefit of manufacturing ceramic PCBs is that they can work well under intense pressure. That is what you look for in situations when heat transfer becomes a problem and the circuit board is threatening to stop working.

5. Unlimited Use Cases

Gone are the days when most circuit boards were limited to one use case. That doesn’t form part of the basis for designing ceramic circuit boards because they have a variety of use cases that include:

- Usable in devices that require higher heat emission and

- Used for powering higher Light-Emitting Diodes (LEDs).

Conclusion

Ceramic Printed Circuit Boards (PCBs) are not only durable but also versatile. You can contact us today so we can help you design your ceramic PCBs in a way that they will meet your PCB needs.

Comments are closed