As the electronics industry investigates new ideas and technologies to remain competitive, many businesses seek to cut the time and expense associated with prototype and small-scale manufacturing. As a result, in recent years, short-run PCB assembly has become an increasingly prevalent solution. We will dig deeper into short-run PCB assembly from the following information. We will explore the iterations to follow to achieve excellent PCB, the factors to consider when choosing a short-run PCB assembly manufacturer, some popular manufacturers, and the pros and cons of short-run PCB assembly.

What is short-run PCB assembly?

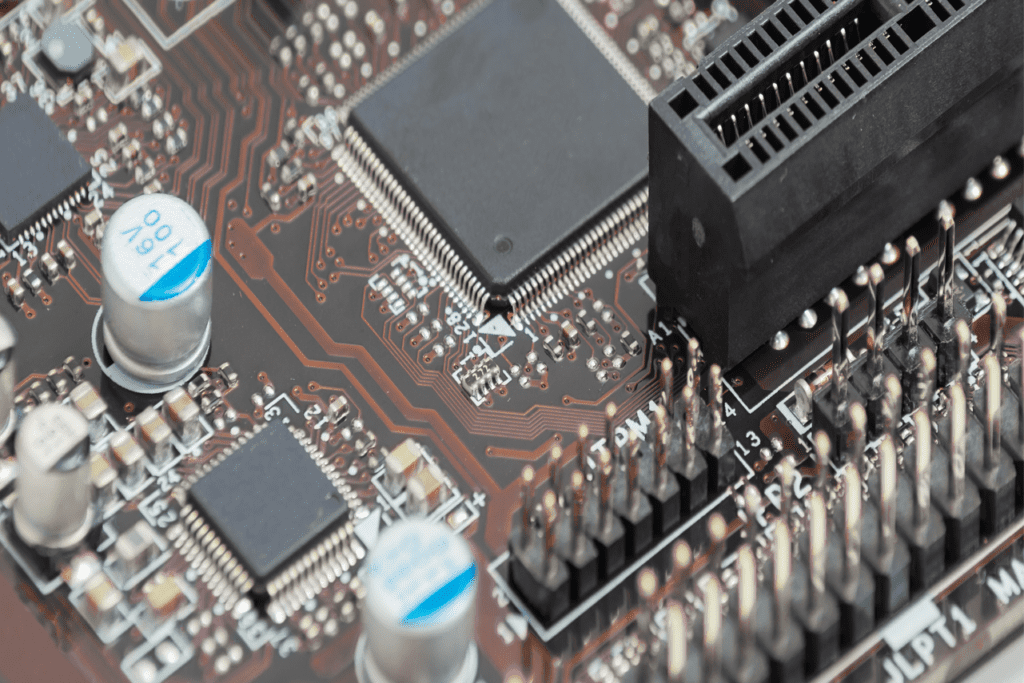

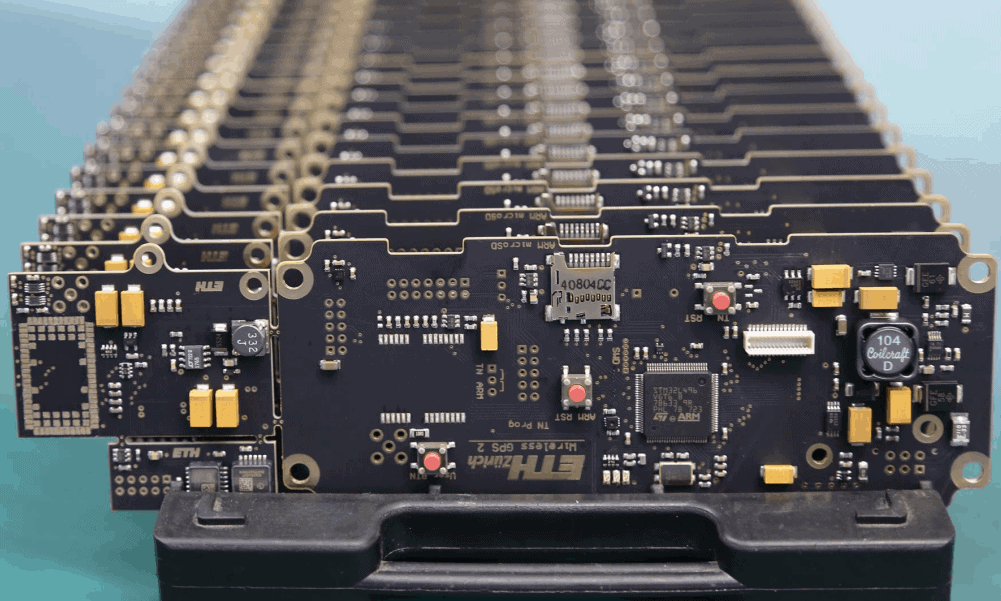

Short-run PCB assembly constructs printed circuit boards in small batches, usually 10–100 pieces, often referred to as “prototyping” or “low volume assembly,” which engineers generally carry out by hand through manual assembly techniques. Typically, short run PCB assembly is useful when testing a new product prototype or produce a limited quantity of a unique product needs.

Steps To Follow For A Short-Run PCB Assembly Process

The following is an overview of a typical short-run PCB construction procedure:

- Order your PCBs.

You must obtain your printed circuit boards from a trustworthy manufacturer. Specify the number of layers, the thickness of the material, and any other unique needs.

- Prepare your circuit boards for assembly.

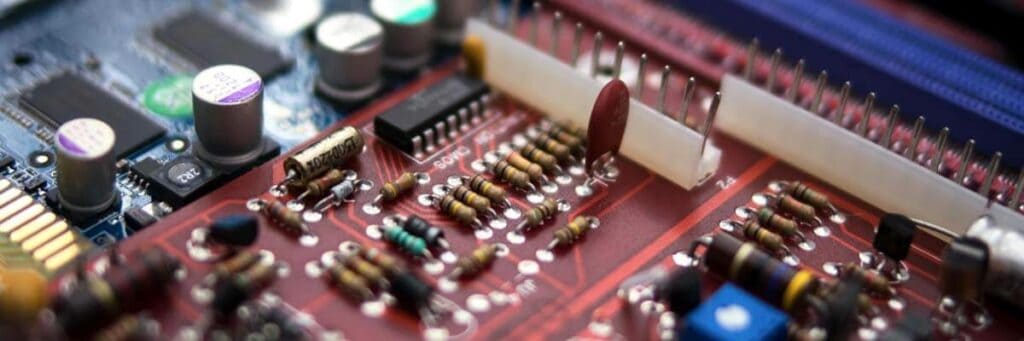

Clean your PCBs and eliminate any dirt and debris. Additionally, you will need to add solder paste to the pads on your PCBs.

- Place your components.

Now place your components on the PCBs using a pick-and-place mechanism. It’s always advisable to position elements correctly and ensure no open or short circuits.

- Reflow your printed circuit boards

After placing the components, heat the PCBs to solder the elements in place. This procedure is known as reflow.

- Examine your PCBs.

Once the PCB has cooled down, an inspection ensures no open or short circuits. Additionally, you must test the PCBs to confirm that they perform correctly.

Factors To Consider When Choosing a Short-Run PCB Assembly Manufacturer

When selecting a company to produce short-run PCB assemblies, there are numerous aspects to consider. Here is a summary of some of the most crucial things to think about:

1. Location: The manufacturer’s location is crucial for two reasons. The first is how much it will cost to send the PCBs to you. Second, it could impact how quickly completion of the assembly process will be. Therefore, a factory near you should be your first choice if you urgently require PCBs.

2. Price: Also, consider the price associated with the assembling procedure. Before making a selection, you should request quotations from many different manufacturers.

3. Quality: The assembly process’s quality is another crucial aspect. Ensure your selected company has a solid track record of creating high-quality goods.

4. Capabilities: Verify that the manufacturer you select can construct your PCBs in the number you want. Some producers can only put together a certain number of PCBs at once.

5. Turnaround time: Again, consider the assembly process turnaround time. Make sure the manufacturer you select can adhere to your deadlines.

6. Customer service: The manufacturer’s customer service will help you be sure that the manufacturer is approachable and eager to respond to any queries you may have before making your decision.

7. References: You could also contact the manufacturer for customer references. You may get a sense of the manufacturer’s product and service quality from this.

8. Warranty: The manufacturer’s warranty helps you confirm that the company you select provides a solid item guarantee.

9. Delivery: Assess the manufacturers delivery method. You should confirm that your chosen manufacturer can deliver the PCBs on time.

10. Certification: Also, consider your short-run PCB manufacturers’ certification. Make sure a good body accredits the manufacturer before choosing them.

Top 5 Short Run PCB Assembly Manufacturers in the World

The following are some of the most popular Short Run PCB Assembly manufacturer companies across the globe:

i. Cartel Electronics

Cartel Electronics has been in business since 1991 and specializes in low-to-medium volume manufacturing runs for short-run PCB assembly. Based in San Diego, California, Cartel provides services to various medical, aerospace, military, and commercial sectors.

Cartel, a family-owned and -operated organization, has a robust dedication to giving its clients the most outstanding PCB assemblies and customer support. “Quality First, Customer Always” is the company’s motto.

Cartel’s PCB assembly specialties include surface-mount (SMT), through-hole (THT), and mixed-technology assemblies. A pick-and-place machine, reflow oven, wave soldering machine, and manual assembly stations are just a few of the company’s many assemblies’ tools.

Design for Manufacturability (DFM) evaluations, component procurement, and assembly testing are just a few of Cartel’s value-added services to its clients. Additionally, the business provides a wide array of engineering and technical support services.

Furthermore, Cartel complies with the Restriction of Hazardous Substances (RoHS) directive, and holds the ISO 9001:2008 certification. The firm offers its PCB assembly services to consumers all around the world

ii. Assembly Solutions

Assembly Solutions has been a US-based, family-owned provider of high-quality, reasonably priced electronic manufacturing services since 2001. (EMS). Additionally, they have an excellent dedication to continual development, adaptability, and client service. Furthermore, their goal is to give to their clients the most incredible experience possible by offering high-quality goods and services that are timely and available at a reasonable price.

Also, the company specializes in assembling printed circuit boards in short runs with rapid turnaround (PCBs). From startups to fortune 500 organizations, the company work with businesses of all sizes across various sectors. Additionally, it can manage projects of any size or complexity since it has the experience and capacity to do so.

Notably, they have a state-of-the-art plant headquarters at the center of the electronics manufacturing sector in Southern California. Typically, the company fits its assembly lines with the newest technology, and has a highly talented and experienced team of personnel. In addition, its procedures are ISO 9001:2015 certified.

From prototype to production, the company provides the complete spectrum of EMS services, including:

- PCB layout and design

- Board assembly

- Sourcing of components

- Examination and testing

- Shipping and packaging

iii. Sanmina

Sanmina Corporation is a publicly listed EMS (electronics manufacturing services) provider based in San Jose, California. The company offer design, engineering, production, and logistics services to original equipment manufacturers (OEMs) in the aerospace, defense, industrial, medical, networking, and telecommunications industries.

Since 1980, Sanmina as a maker of printed circuit boards (PCBs), has been in business. In 1994, the industry paid $2.6 billion to buy SCI Systems, a big EMS company. The acquisition made Sanmina the world’s largest EMS firm.

Sanmina has more than 250 sites in 30 countries spread over six continents. The firm provides various services, including design and engineering, prototype and production, logistics, and aftermarket support.

The company’s end-to-end capabilities enable OEMs to outsource their entire product development process to Sanmina, including design, engineering, prototyping, manufacturing, logistics, and aftermarket services. Consequently, the comprehensive strategy eliminates the need for OEMs to manage multiple suppliers, saving time and money.

Sanmina has a long history of providing services to the aerospace and defense industries. With an emphasis on avionics, missiles, and ground vehicles, the company is the leading provider of EMS services to this industry.

Sanmina is also one of the largest providers of EMS services to the industrial sector. Electronics assembly, testing, inspection, mechanical assembly, and packaging and labeling are some of the company’s capabilities in this field.

Notably, Sanmina is the foremost provider of EMS services to the medical industry.

In the networking and telecommunications industry, Sanmina offers EMS services for various products, such as routers, switches, and other network equipment. The business is also a leading provider of EMS services to the cable and satellite TV industries.

iv. Caliber Electronics

Caliber Electronics provides high-quality printed circuit boards for a range of short-run applications. The organization has over 25 years of industry expertise and a reputation for producing high-quality goods and services. Caliber Electronics is a family-owned company established in the United States that serves a global customer base.

Notably, Caliber Electronics specializes in producing short-run printed circuit board assemblies. In addition, the firm provides several services, including design, manufacturing, body, and testing. Additionally, the company can manufacture a range of printed circuit board types, including single-sided, double-sided, and multilayer boards. In addition, Caliber equips its manufacturing plant with the most advanced technologies and machinery. As a result, Caliber Electronics is always willing to providing its clients with the finest goods and services.

Some of the services it provides result from its customers’ specific demands. Caliber Electronics delivers a selection of custom-tailored products to satisfy the individual requirements of its customers. The firm offers comprehensive design, manufacturing, assembly, and testing services. The firm also provides partial services, including design and fabrication. Caliber Electronics has an excellent commitment to providing its clients with the best goods and services available.

The engineers and technicians of Caliber Electronics are strongly responsible for providing its clients the highest quality products and services. Furthermore, we equip the company’s manufacturing plant with the most advanced technologies and machinery. As a result, we are devoted to providing our clients with the finest goods and services.

Caliber Electronics is an ISO 9001:2008 and ISO 13485:2003 certified manufacturer, and its facilities are available in the United States, Europe, and Asia.

v. EMS Technologies

EMS Technologies is a Canadian firm that offers PCB assembly on a short-run basis. The firm has more than 25 years of expertise in the electronics manufacturing sector and provides a vast array of services to its customers. EMS Technologies offers a team of highly qualified and experienced engineers that can provide clients with a comprehensive solution for their short-run PCB assembly requirements.

Additionally, EMS Technologies provides a vast range of services for short-run PCB assembly, including circuit board design, component procurement, assembly, testing, and final delivery. The company’s highly qualified and experienced engineers supply clients with a comprehensive solution for short-run PCB assembly. In addition, it has equipped the state-of-the-art facility at EMS Technologies with cutting-edge technology and tools to offer clients the highest level of service possible.

EMS Technologies has a tangible devotion to offering its clients the finest quality services and products. Furthermore, the firm has a rigorous quality control system to guarantee that all goods satisfy the highest quality requirements. EMS Technologies holds ISO 9001:2008 certification, and its products are RoHS-compliant. In addition, Canadian Standards Association (CSA)accredited the EMS Technologies.

EMS Technologies offers a variety of short-run PCB assembly services, such as:

- Circuit board design

- Component sourcing

- Assembly

- Testing

- Delivery

Benefits of Using Short-Run PCB Assembly

- Increased design versatility — With short-run PCB assembly, businesses may be more adaptable with their ideas, enabling companies to experiment with various designs and make adjustments without worrying about the high costs of conventional PCB fabrication.

- Lower prices – Since expensive tooling is not a necessity, short-run PCB assembly may be much cheaper than conventional techniques, especially when the board production volume is low.

- Fast accomplishment-Shot-run PCB assembly will perform much faster than conventional techniques without substantial tooling requirements, which might benefit businesses that need their boards rapidly.

- Improved quality control-With short-run PCB assembly, businesses have better control over production. As a result, they are making it advantageous to maintain quality control and fulfilling strict deadlines.

- Reduced risk – Short-run PCB assembly is cheaper and faster, and therefore entails less business risk, resulting in a significant benefit for startups and small enterprises seeking to enter the PCB industry.

Drawbacks of Using Short-Run PCB Assembly

There are various problems associated with short-run PCB assembly, including:

- Limited capabilities – Short-run PCB assembly can only implement simpler designs. Thus, this might be a drawback for businesses that want more intricate boards.

- Poorer quality – Due to the poor hand performance of short-run PCB, the boards’ quality might be inferior to those manufactured using conventional processes. In additionally, this is especially true for simple assemblers.

- More significant likelihood of mistakes — With short-run PCB assembly, there is a greater likelihood that errors may occur. As a result, this might be a disadvantage for firms that want flawless boards.

- Incompatible materials – Certain materials utilized in short-run PCB assembly may not be compatible with conventional procedures. It might be problematic for businesses that must use particular materials for their boards.

- Limited resources –Short-run PCB assembly frequently necessitates the use of restricted resources. Consequently, businesses that must generate significant boards may find it difficult to achieve.

Conclusion

In conclusion, short-run PCB assembly is an excellent alternative for people that need to build a limited number of PCBs fast and effectively. Using this method, it is pretty easy to make a variety of PCBs, including prototypes and limited production runs. However, when choosing a manufacturer to attend to your short-run PCBs, you must consider some factors, as apparent in the above details. Furthermore, the above information has highlighted some of the most capable manufacturers of short-run PCB assembly. Notably, there are many benefits to using a short-run PCB assembly service, but the method also comes with some demerits.

Comments are closed