Turnkey printed circuit board assembly is a service offered by PCB producers. They handle every step of the PCB project from start to finish. This includes sourcing electrical parts, PCB production, PCBA testing, PCB assembly, final fabrication, shipping, and testing.

A PCBA is deliverable when dealing with a turnkey printed circuit board assembler. Because all the steps get completed in one location, this article will go over the various advantages of turnkey PCB fabrication.

What is the meaning of “Turnkey” in PCB Fabrication?

Projects are “turnkey” if they get sold to the customer in fully operational condition. When it comes to the printed circuit board assembly. A “turnkey assembly” service means that your provider takes care of everything for you. The PCB gets assembled, and components get sourced by the supplier.

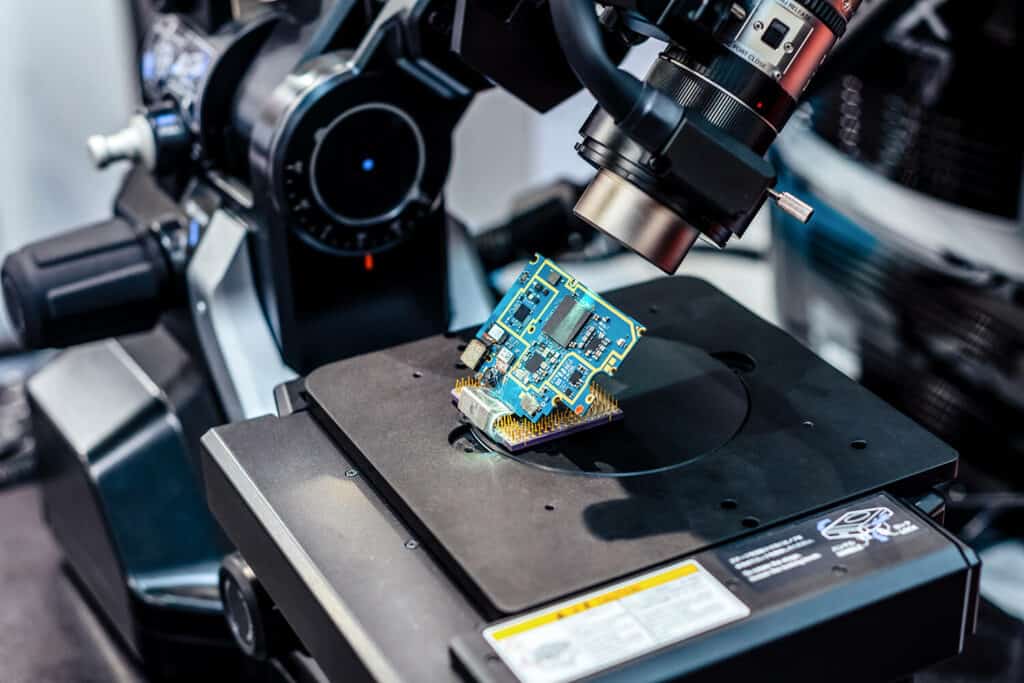

Turnkey PCB manufacturing often employs cloud-based technology. Also, robust equipment helps in assembling circuit boards with better efficiency and volume. This is much better than the one that is achievable by small and medium-sized firms working alone.

Full Turnkey vs. Partial Turnkey Assembly Services

There are two levels of PCB manufacturing turnkey service: full and partial. When only a part of the assembly procedure gets contracted, the service is called “partial turnkey.” When a project is just “half turnkey,” the developer of the technology is still responsible for some aspects of the supply chain process. Participation in either purchase or production is possible. According to the consignment method, the technology developer gets responsible for sourcing. It includes inspecting and shipping all necessary components to the manufacturer.

Partial turnkey solutions can speed up the production cycle. It also saves costs for organizations that already have most of the required parts on hand. However, if you do not have the necessary components, don’t know where to get them, or don’t know which ones would work best with your electronic circuit layout, a full turnkey solution is the better choice.

Major Advantages of Turnkey Assembly Services

1. Prototyping

A prototype is an early model of an item that allows the producer to test out concepts. It also demonstrates the reasoning behind a proposed feature before committing significant resources to its full development. Turnkey drawings are helpful because they allow group members to better comprehend and operate the board.

One reason prototyping is useful for PCB assembly companies is that issues are identifiable before they become too costly to fix. Before the final product gets made, any problems with the production process that are discoverable will get fixed. In order to save time and money. Turnkey PCB manufacturing is a benefit to startups and small businesses. It’s quick to make because the vendor handles everything.

2. Superior Quality Purchases

One of the most significant benefits of using a company is the assurance that you will receive a superior end result. It provides turnkey PCB fabrication services. You may receive a top-tier product in no time at all with the help of turnkey PCB fabrication solutions. It provides excellent board design in addition to skilled solder of surface-mounted elements. Recently, miniaturization has been trending upward. It necessitates the deployment of specialized machines. The machines are capable of forming reliable solder junctions even on the tiniest of elements. High-quality results get guaranteed with turnkey PCB manufacturing solutions.

3. Meaningful Impression on Lenders

Real evidence that a product is performing as promised is more likely to impress shareholders than a flashy presentation. When you work with turnkey providers, you can rest assured that the boards you buy will be of the highest quality. And they will bear your company’s branding. Professional boards can help you achieve the desired style and feel. In addition, having a high-quality item to show investors will help solidify their beliefs. Your business is ready for mass manufacturing.

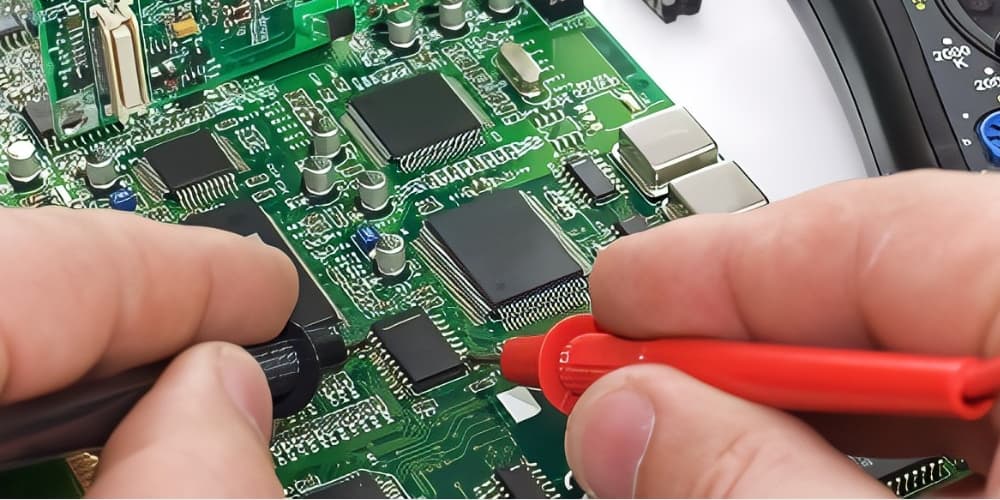

4. Identify Issues Quickly

Another major perk of using turnkey PCB manufacturing services is that problems get identified early on. Also, they help in correcting mistakes. Because the turnkey service provider examines the layout before production. Any problems are discoverable as soon as an error is found. It becomes fixable by making a modification. Errors can prove to be extremely expensive, particularly if they are found late. Instead, turnkey PCB fabrication services allow you to enjoy the advantages of early problem identification. While also laying the groundwork for repeatable, effective design processes in future iterations of your product.

5. It is a Time-Saver

Another perk of using turnkey PCB manufacturing services is the time and energy they free you up to use. It helps in growing your company. The group won’t waste time searching for high-quality components. By freeing up so many hours, productivity is greatly increased. One of the benefits of using PCB fabrication services is the speed. The speed with which orders can get processed and fulfilled. Without it, business owners risk losing credibility if crucial deadlines get missed.

6. Single Contact Point

You can rest assured that making quick adjustments to your business will be simple if you have only one contact point. With several suppliers, even a seemingly insignificant adjustment might cause a delay on your side, and miscommunication can lead to a host of other problems. Turnkey PCB manufacturing services give you peace of mind by providing one contact point with a coordinating department or individual for your project.

7. Cost Effective

Young business owners should bear in mind, among many other factors, the importance of cutting costs without sacrificing quality. Turnkey solutions from the many available PCB manufacturers are offered at reasonable prices. When purchasing or dealing with PCB components, keep in mind that you’ll have to manage shipment on your own, which will result in additional expenditures. In contrast, you can save money by using turnkey PCB manufacturing services.

8. Budgeting and Saving

Turnkey PCB manufacturing services also facilitate budgeting, which is a major benefit. In this case, your service provider can help you with both your current costs and the rising manufacturing costs that come with them. Something that will aid you in making accurate estimates of the ultimate product’s price. It is considerably simpler and less time-consuming to manage your budget when you use turnkey PCB fabrication services because you may acquire quotations right away. Even better, manufacturing set-up time can be cut down to size with repeated orders.

9. Upgraded Administration

The elimination of the need to coordinate with several suppliers is another major perk of turnkey manufacturing solutions. In addition to the obvious time savings, this kind of communication eliminates the potential for misunderstandings to arise, which is especially useful when working with multiple suppliers. When you work with a reliable turnkey provider like WellPCB, you only have to worry about one place to go to get all of your circuit board needs to be met. You can get in touch with us whether you need a PCB with single-side, double-side, or some other kind of PCB. We will make sure everything goes smoothly. If you go with a turnkey provider like us, you can rest easy knowing that we’ll take full responsibility for making sure your product gets to you when it’s supposed to. With the help of our turnkey PCB manufacturing services, you can rest easy knowing that your business will be run more efficiently.

10. PCB Board Modifications

In increasing numbers these days, consumers expect individualized attention from businesses. If you take a look, you’ll see that a lot of individuals favor buying unique items that are customizable.

It’s common to think of turnkey manufacturing as being conventional. Whether the context is for PCB electronic fabrication solutions or not. Since turnkey solutions can provide the perks connected with customizing while carrying the cost advantages, there is no way to be too far from reality when talking about PCB manufacturing services. The services can be provided on a turnkey basis.

11. Facilitates the Prediction of Production Expenses

If there is a single characteristic that is essential for business owners. It would have to be the ability to accurately organize their finances. With turnkey PCB manufacturing services, entrepreneurs may choose their production costs. Turnkey PCB manufacturing services allow PCB makers to enjoy sales economies. Also, they estimate future production costs. They are especially useful during the prototyping phase of product development. As a turnkey provider, WellPCB offers our customers the opportunity to consolidate and implement a number of smaller orders into a single, larger one.

12. Extra Services

Many of the available turnkey service providers additionally provide their customers with a variety of complementary offerings. To stay competitive, most firms look for ways to increase the value they provide to customers. The majority of turnkey vendors also offer their customers extra offerings. The offerings include stock keeping and shipping. There is no way to overstate the value of such offerings. This is especially true for startups and independent ventures. These supplementary offers are only one way to help entrepreneurs save money. Also, they help in getting an edge in the market. Turnkey PCB manufacturing services have several advantages. They include but are not limited to the following.

13. The Simplicity of Keeping Tabs

Full turnkey board fabrication shortens the time to market. Besides this, it also facilitates straightforward tracking. Following the next step will demand us to have different professionals to oversee all the stages. Sub-section surveillance takes place within the company’s structures. It allows the entire process to get monitored as a whole. Within the organization, there are expert engineers who will make sure that each step is perfect. It is your responsibility to ensure that the finished work meets expectations. You can monitor the progress of your order in real time by visiting the provider’s website. The reassurance of working with a single supplier gets amplified if that supplier is also responsible for final product assembly.

14. Lead Time Reduction

Then picture goes through each individual stage of PCB assembly by hand. The first step is to hire a PCB production business. Then, come up with a plan for sourcing the necessary parts. Finally, arrange for an assembly contract if the companies are present in different countries. The process will take considerably longer. In full turnkey PCB manufacturing, all these processes get carried out simultaneously. Having to coordinate with fewer parties during the bidding process is a huge time saver. Minimizing meetings, emails, and quotes helps keep projects from getting skewed. There’s a lot of room for error if you have to give three separate quotations. Because of this, the possibility of a defective product rises.

15. High-Quality Components

The responsibility of parts acquisition is given to the expert manufacturers. Their long-term relationship and expertise with the vendors help them to achieve the greatest part quality. If you have to buy the parts yourself, there’s a good risk you’ll get a bad deal. This is because you lack the knowledge to adequately evaluate the product’s quality. In fact, if you’re a one-time customer, your chances improve.

Final Verdict

In conclusion, business owners can profit from using the services of a turnkey PCB manufacturing provider. Because it allows them to easily bring to life a wide variety of concepts. When you consider the benefits of speed and adaptability, you will have much more leeway to find the best option. The notion that your progress is trackable provides much-needed reassurance to business owners.

Turnkey PCB fabrication services are an effective option for obtaining the required components. If you hire a professional producer for help. You won’t have to worry about the quality of your work suffering while you focus on other priorities. Do you need BOM to quote services for printed circuit boards? If that’s the case, then please contact our team of PCB experts.

Comments are closed