Ever heard the term “quick turn circuit boards” and wondering what it is all about? There are two major concepts therein – “quick turn” and “circuit boards.” While the former refers to the fast-paced process of doing something, the latter refers to the Printed Circuit Boards (PCBs). Thus, the term “quick turn circuit boards” refers to the speedy process of getting a Printed Circuit Board (PCB) project completed in good time.

The Concept of Quick-Turning PCBs

Why are circuit boards subjected to quick-turns in the first place? The major reasons for this accelerated process of designing PCBs include but are not limited to:

- Faster PCB Assembly: Depending on the manufacturer, the whole process can take anywhere between 24 hours and 48 hours. That is why most PCB consumers prefer quick turn circuit boards because it accelerates the design process.

- Flexibility Purposes: Generally, Printed Circuit Boards (PCBs) are meant to be reconfigurable, thus making it easier to modify the original designs. With the quick turn circuit boards process, the flexibility becomes higher, as the boards can be made heat-resistant, bendable and compact. It is possible to do all these, because of the use of flexible circuit boards for the design.

- Cost Reduction: Using quick turn circuit boards can be a great way to save on PCBs, as the overall cost is minimal. Thanks to the limited resources and the less-time-spent, you can get it at the fraction of the original circuit board cost.

The Quick Turn Circuit Board Design Process

When it comes to choosing a quick turn PCB, the focus is usually on the time-spent. As mentioned earlier, it can take anywhere between a day and 2 days to get the job done.

However, the time-spent may be extended and so will the design iterations. Here are a few considerations on the factors influencing the quick turn circuit boards design process:

- Construction Complexity: The more complex the circuit board design is, so will the time-spent and the cost increase too. This informs the reason why most PCB consumers opt for the two-layer PCBs that take less time and cost less.

- Volume of Parts: How many quick turn circuit boards do you need? If the scope is between 1 and 10, you can be sure that the manufacturer will complete it in a few days. But if the volume runs into hundreds, the time-spent could take a couple of weeks.

- The Cost-Factor: The overall cost of manufacturing quick turn circuit boards is relative to the volume of the parts, the design process and the type of construction needed.

With that being said, let us now look at some of the stages involved in the production of quick turn circuit boards.

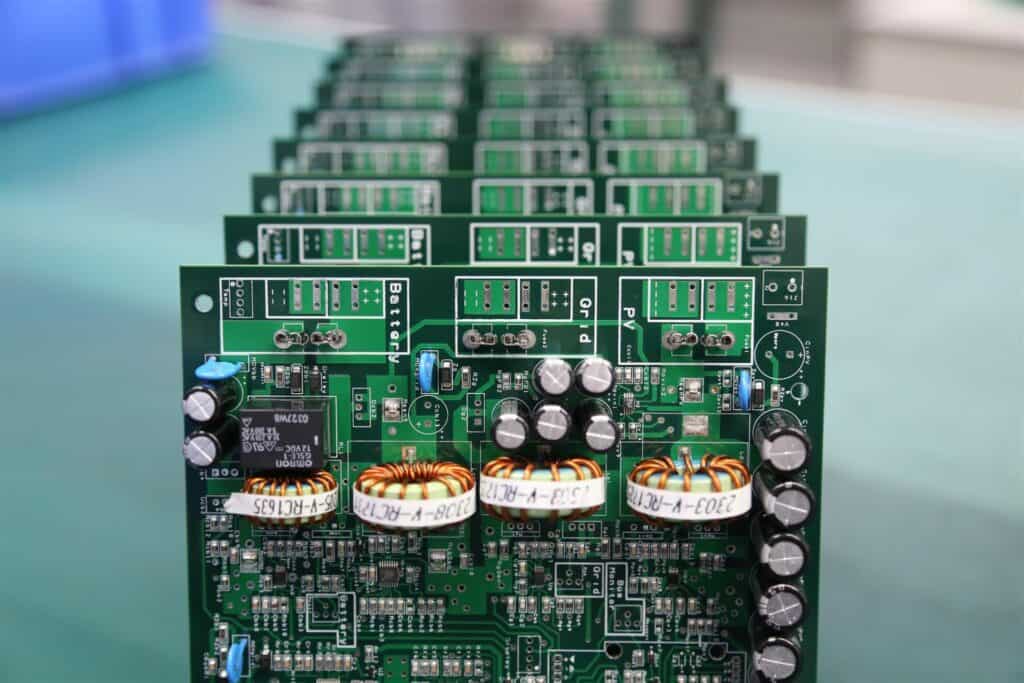

1. Making Prototypes of Quick Turn PCBs

The very first step is to make a prototype of the circuit board. However, before this can be done, the consumer must have contacted the manufacturer for the first stages of discussion. During this time, the manufacturer requires the consumer to provide as much information as possible about the design.

The following are some of the expected provisions to be made by the consumer or client:

- Gerber File: The consumer is to prepare the quick turn circuit boards expectations (the design) and compile the same into a Gerber File. The file is to be sent to the manufacturer.

- File Review: With the Gerber File now in its possession, the quick turn circuit boards manufacturer will have to carry out the Design for Manufacturability (DFM). The DFM is a sort of “compliance test” to ascertain that the quick turn circuit boards design process/data matches the IPC standards.

- Order Confirmation: The quick turn circuit boards manufacturer will then get back to the consumer on the status of the order. If the content of the Gerber File matches the IPC standards, the manufacturer will let the consumer know the next steps of processing the order before the PCB design starts in earnest.

Now that the order has been confirmed, the quick turn circuit boards manufacturer will then make a prototype or pre-design of the circuit board.

The following are some of the things you need to know about the quick turn circuit board prototypes:

- Small Quantities: The PCBs are usually made in smaller quantities, because of the uncertainty on what the outcome would be. With few quantities available, the manufacturer can improve on the design in the next stage, thereby, minimizing costs.

- Considerations for the Design Rules: The manufacturer also helps the consumer to make an ideal choice of the best quick turn circuit boards, by aligning the boards to the PCB specifications.

- Varied Prototypes: It is also possible for the quick turn circuit boards to make several prototypes of the PCB. That way, you get to see how each of those prototypes can work in the real-world applications.

2. Beta Run Quick Turn PCBs

After the prototypes are made, the next step is to subject the quick turn circuit boards to beta run. Also called the pre-production stage, the beta run stage is a period during which the circuit boards are sent out for the set of uses.

A breakdown of the processes involved is given below:

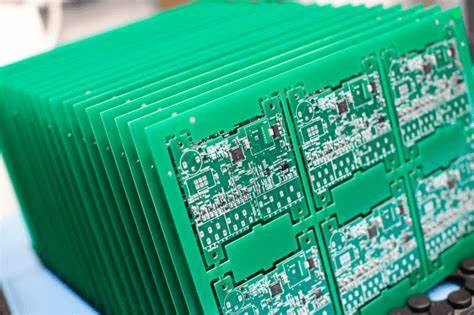

- Batch Production: Just like the prototyping stage, the quick turn circuit boards are made in smaller numbers of manufactured in batches. The volumes produced here can be anywhere between hundred pieces and a few thousands. The major reason for keeping the volumes minimal is that the pre-produced quick turn circuit boards might become the final design. If they don’t function optimally, that could mean discarding the entire production, thereby, wasting money.

- Reliability Testing: The quick turn circuit boards are sent out to the field for reliability testing. A major reason why some PCBs fail at this test is because the materials used are different. It is better to use the same circuit board materials and the same data obtained from the Gerber File during the prototyping stage.

- Error Identification: If you pay close attention, you will find out some of the design errors that need to be fixed. These range from board layout/stackups, drill sizes and tooling arrangements.

With those errors figured out, your quick turn circuit boards manufacturer can now fix them ahead of the final designs of the PCBs.

3. Standard Quick Turn Circuit Board Production

This is the last stage of the quick turn circuit board production. The circuit boards cannot be ready for the final production or getting “pushed into the market” except the errors have been fixed.

Therefore, your quick turn circuit boards manufacturer should address the errors identified in the pre-production stage ahead of getting the PCBs ready for the market.

The following are some of the important factors to note about the standard or production stage of the quick turn circuit boards:

- Volume Considerations: As this is the final design of the quick turn circuit boards, one can expect the orders to be higher. Most times, the consumer has to place an “emergency order” to satiate the needs of the buyers. Despite the high volumes required here, the RayPCB quick turn circuit boards manufacturer can fulfill them in good time.

- Lead Time: This is the time it takes to process the order and get it shipped to the consumer. Just as the name implies, quick turn circuit boards have one of the shortest lead times. However, the lead times can vary, depending on factors like shipping process and designing processes. RayPCB conveniently handles all that and keeps the lead times at the barest minimum, because we use the same circuit board materials and Gerber File data for the board production.

- Cost: The cost of getting the final designs of the quick turn circuit boards is also affordable, as we have a flexible transportation system that reduces the overall shipping costs. We also make an internal handling of everything about the data and circuit board design in-house.

Quick Turn PCB Prototyping and Testing

Quick turn circuit boards can be prototyped and tested at the same time. The tests are done to ascertain the boards’ compliance with the standards set by the Institute for Interconnecting and Packaging Circuits (IPC). Through the tests, the manufacturer also gets to know if the different parts of the PCB are functional.

The following are some of the common testing processes for quick turn circuit boards:

- Functional Testing: This testing method checks if the parts are operating as they should.

- X-Ray Testing: This is the most popular testing method for quick turn circuit boards. It is commonly-used because of the “deepened inspection” of the board’s components.

- AOI Testing

- Visual Testing

What Technology is Best for the Quick Turn PCBs?

The ideal technology depends on a couple of factors, ranging from the speed, cost and design considerations.

Here are some of the popular technologies used when manufacturing a quick turn circuit board:

Through-Hole Technology (THT)

Also called the Through-Hole Assembly (THA), it is a quick turn circuit board design process that involves the insertion or passage of the circuit board components into pre-drilled holes in the circuit board.

After these components are passed through the holes, they are to be soldered. Using a metal solder for this makes the components to hold “strong” or be firm inside the circuit board.

Surface-Mount Technology (SMT)

The SMT process of manufacturing quick turn circuit boards involves the direct placement or mounting of the components atop the PCB’s surface.

It appears to be one of the simplest processes to designing the quick turn circuit boards and that is why most consumers opt for it.

When the electrical components are mounted on the PCB’s surface, they are to be held in place with soldering materials.

Mixed Quick Turn Circuit Board Assembly

This PCB design technology is a combination of the Through-Hole Technology (THT) and the Surface-Mount Technology (SMT).

Sided Component Placements

In this case, the consideration is the placement or positioning of the quick turn circuit boards either on a single side or on double sides.

If the boards are to be placed on a single side, the process would require the placement of the electrical components on just one side of the Printed Circuit Board (PCB).

If, on the other hand, the electrical components are to be double-sided, they are to be positioned on both layers of the PCB.

Working with a Quick Turn PCB Manufacturer

If you are to choose the best manufacturer for your next quick turn circuit boards, how would you do that?

Here are a few clues on how to pick the best manufacturer for these kinds of circuit boards:

Is the Manufactured Vested in “Quick Turn”

A couple of PCB manufacturers have started adding quick turn circuit boards to their design processes, but how many of them offer that speed?

The first thing you want to do is check the average lead time of the manufacturer. If it takes the manufacturer a lot of time to get a prototype ready, it might mean that the company is not really vested in “quick-turning” the PCBs.

The Cost is Important

Due to the fewer circuits required, the less design iterations and the speed, quick turn circuit boards have become very affordable.

However, the cost of working with the manufacturer might vary. You can ascertain the cost-factor by:

- Comparing the quotes from different manufacturers.

- Considering the quality of the equipment used for the designs.

The goal is to prioritize working with a quick turn circuit board manufacturer that has the same price as your budget has.

Check that the PCB Assembler Adheres to Quality Specifications

The quick turn circuit board manufacturer should align the services with the subsisting international standards and quality specifications. In addition to ensuring that the circuit boards comply with the IPC standards, the manufacturer should also have the following in place:

- UL-approval for circuit board prototyping.

- Compliance with the RoHS standards.

Final Words on Quick Turn Circuit Boards

The quick turn circuit boards can be designed in a few days, typically between a day and 3 days. Your best bet is to pick the manufacturer that has the best equipment, complies with the existing standards and assures of the fastest lead time.

RayPCB can process your quick turn circuit board orders in the shortest time possible. As experienced PCB manufacturers, we understand how important it is for you to get the boards ready-to-market in a few days and we are ready to put in the work to make that a reality.

Comments are closed