This is the correct spot for you if you need a PCB with only one layer. Everything you want to learn about the one-sided board is present in this article. We will also cover the upsides and downsides of employing them. By the time you reach the conclusion of this article. You must have a firm grasp on what single-sided PCBs are as well as whether they’re suitable for your current endeavor.

What is Single Layer PCB?

In electronics, a PCB with only a single side of conducting materials is called a single-sided or single PCB. This side is normally constructed of the copper layer, and the circuit layout gets etched by the manufacturer. The single-side PCB, the simplest form of the circuit board, can be used for a wide range of purposes.

Single Sided PCB Stack up

As evident from the example image, a single-layered PCB consists of a single side of conducting materials. The circuitry is implementable in this layer. Additions to the PCB will have to be made on the opposite part of the board.

Raw Material of Single Sided PCB

· Aluminum

For single-layered PCBs, aluminum is typically used. Additionally, substrates made from aluminum are the most reasonably priced option. Aluminum’s primary benefit is that it conducts heat effectively. Therefore, it is capable of rapidly dissipating heat.

· FR4 Grade Fiberglass Laminates

In single-sided PCBs, FR-4 is frequently utilized as the dielectric. It’s manufactured out of flame-resistant fiberglass, hence the “FR” designation. FR- is preferable to other dielectric materials due to its low price and high heat resistance.

· CEM 1

The CEM-1 is a single-layered PCB that gets produced at a minimal cost. In addition, it is constructed out of epoxy and fiberglass. CEM is preferable to other dielectrics due to its low price and high heat resistance.

· CEM 3

Epoxy and fiberglass make up the bulk of CEM-3’s construction. Further, it has high heat resistance for a single-sided printed board. CEM stands out among other dielectrics because of its low price and high heat resistance.

· Copper Base

To make a copper single-sided circuit board, a light coating of copper foil is bonded upon a dielectric material. The superior thermal and electrical conductivity of a copper single-sided circuit board is its primary benefit. Because of their superior heat dissipation properties, single-sided PCBs made of copper are typically reserved for usage in high-power systems.

Benefits of Single-Sided PCB

Single-sided PCBs provide various advantages.

· Less expensive

As fewer materials and less sophisticated equipment get used in the manufacturing of single-layered PCBs, their low cost gets reflected in their low production cost. Because of the low production costs, this method is well-suited for mass manufacturing or large-scale orders of low-density layouts.

· Less complicated

Single-sided PCBs have the advantage of being simple to design. Choosing a one-layered PCB will lessen the likelihood of an improper design and spare you the anxiety of design blunders. As a matter of fact, you can get a near-perfect prototype with little effort at all.

· Easily assembling

Since there is only a single side, assembly procedures, including inserting, soldering, drilling components, and desoldering, become simplified.

· More Dependable

A single-sided PCB’s design simplicity makes it more durable. In addition to its high efficiency and long lifespan, the board is also quite reliable. That is to say, blunders during production (such as a faulty circuit) are unlikely to occur.

· Easy to test and repair

A single-layered PCB is much less complicated to test and fix if something goes wrong than a multilayered PCB. In addition, since there is only one layer in this PCB design, troubleshooting is simple. Thus, finding and fixing the source of the mistake takes less time.

Disadvantages of Single-Sided PCB

Single-sided PCBs have many advantages, but they also have some drawbacks.

· Limited connection points

Space and connections are at a limitation on single-layered circuit boards. So, any circuit that needs to assemble a lot of components and lots of connections shouldn’t use a PCB with only one layer.

· Lower speed

The efficiency and power consumption of a single-layered circuit board are both reduced because of the limited number of connection points between its components. Therefore, applications that necessitate a large number of connections are not well-suited to slower transmission and operating speed.

Major Kinds of single-sided PCB

Single-sided (PCBs) come in five distinct varieties.

· Single-sided Rigid PCBs

It’s a single-sided PCB, the likes of which construction is only possible from rigid materials like fiberglass. Because of the boards’ stiffness, they are safe from getting bent or broken. These are widely used in a variety of electronic devices, from power supplies to calculators and beyond.

· Single- sided Flexible PCBs

It is a variation on traditional single-layered circuit boards, except the material used is pliable rather than hard. And they make use of plastics in their construction. Single-sided flexible PCBs are more expensive than their stiffer counterparts but offer some advantages.

· Single sided High-frequency

These circuit boards are a special instance of single-layered boards and are usable at frequencies of several gigahertzes. PPO and Teflon are the preferred choices for making the boards. Considerations such as water absorption, dielectric loss, and thermal expansion are crucial while searching for HF single-sided PCBs.

· Single- sided rigid-flex

These single-sided PCBs are made of a plastic and glass fiber composite. Fiberglass and plastic are two examples of one-sided materials. The advantages of multilayered boards over single-layered flexible and rigid PCB get reduced size and weight, among others.

· Single- sided aluminum PCBs

This PCB has one layer of insulation on top of an aluminum sheet. The layout of these boards is quite identical to the design of copper boards, with the main difference being that the later uses the substrate of copper rather than aluminum substrate.

What is the Difference between single- sided & multiple- sided PCB?

· Process of Manufacturing

In multilayered PCBs, the base material and the prepreg sheets get bonded using heat and high pressure.

The fabrication of the single-layered PCB typically involves a number of CNC machining procedures. The process includes activities such as drilling, cutting, putting on graphics, applying a soldering mask, etching, and printing.

· Usage

Some simple instruments can use a single-layered PCB, while more complicated devices, such as smartphones, require a multilayered PCB.

· Material

Single and double-sided circuit boards (PCBs) are made from materials like polyimide, Teflon, CEM, FR-4, and metal, respectively. Copper, however, remains the preferred metal for this purpose.

· Production cost

Compared to multilayered PCBs, single-layered PCBs have lower production costs. Good starting materials, lots of time and effort put into the production, and competent workers all play a role.

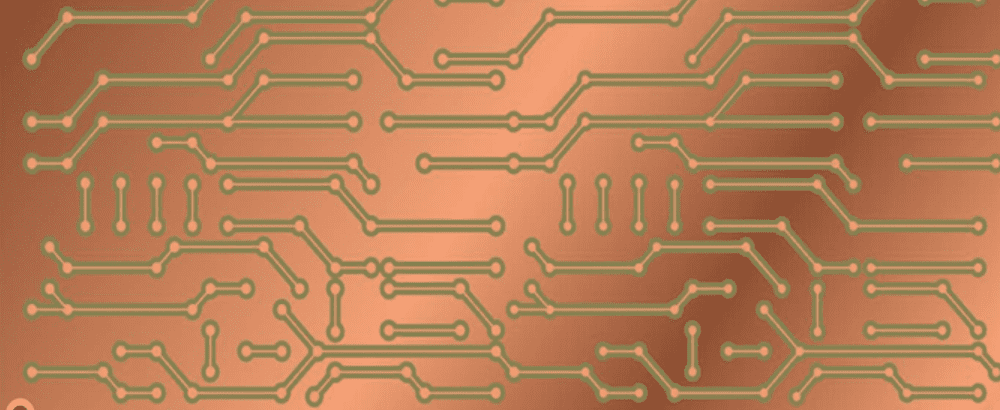

Fabrication of single PCB

· Laser imaging

Before any additional work gets performed on a multilayered PCB, the areas that will form the metallic ground, pads, and trace can get applied using LDI.

· Lamination & oxide

After a circuit board (PCB) has been completely etched away, an oxide chemical technique gets used to reinforce the binding of the internal layers. Next, layers of copper foil and prepreg are bonded together and heated in a hydraulic cylinder.

· Drilling

Vias can be made in a multilayered PCB by lasering or drilling through the sides to create a path for the signals to go between the layers. Drilling on multiple panels at once is the most efficient. However, the optimal number varies based on the kind of through being utilized.

· Coating of copper & dry film

After the drilling of holes into the surface, the remaining debris and glue are chemically and mechanically removed.

· Procedures for etching

Copper electroplating gets created by immersing the panels in a solution of sulfuric acid and copper sulfate after it has been equipped by exposing the conducting pattern and drilling holes.

· Solder mask & silkscreen

Protect the circuit board (PCB) against damage by applying a soldering mask and exposing it to UV light in the same manner as done with the photoresist.

· Preparation, inspection & testing

The fabrication of the circuit boards necessitates subsequent testing and inspection to ensure proper functionality before the boards can get combined.

Considerations while constructing a single- sided PCB

If you follow these steps, building a single-layered PCB won’t be difficult at all.

1. Types of vias

In summary, the vias are what make it possible to make linkages between the boards’ many layers. Different types of boards require different numbers of vias to accommodate the varying panel thicknesses. There are several options available to you: Micro, Buried, thru-the-hole, and blind.

2. Traces Thickness

Weight of a circuit board is directly proportional to the quantity of copper utilized in its traces. Even though most circuit board designers only use a few oz of metal.

NOTE: Using the wrong tracing thickness can cause problems with soldering and lamination.

3. Design of the one-sided PCB

If you want to figure out the basic characteristics of your PCB, you need to construct a stacking guide. The money and time needed for PCB production and the necessary raw materials are determinable by the PCB’s complexity.

4. Construction restraints

Always clarify your requirements in advance to ensure that your created PCB is up to par with your expectations. Considerations for engineering time, component location, layer assignments, flight time analysis, and more should be made.

5. Best quality of signals

Take note of signal rising and falling times, drive intensities, and impedances. You could see if your attempts paid off by conducting tests both prior to and after you created the layout.

Major Application of Single-Sided PCB

One-layer PCBs may be straightforward, yet they have a place in high-complexity electronics. Calculators, printers, copiers, security cameras, coffee makers, power supplies, relays, hard drives, vending machines, detector products, light-emitting diode (LED) lights, washers and dryers, and radio/stereo equipment are just some of the many intermediate and complicated electrical gadgets that can benefit from their use.

Conclusion

A single-layered circuit board (PCB) has applications in many different kinds of applications and gadgets. If your goals are achievable with a single-sided PCB, then you should use it. These days, a single-layered PCB can power almost any small home appliance. Even in this day and age, it is impossible to overstate the value of single-sided PCBs.

Therefore, the next time you use a kitchen blender, coffee maker, or any other electronic device in your house, remember the crucial role that a single-layered PCB played in making that item possible. Though, multilayered PCBs are a need when dealing with sophisticated circuits.

Frequently Asked Questions

What is the price of a single-sided PCB?

Many variables affect how much money you’ll have to spend on a single-layered PCB. These considerations can get broken down into two categories: primary and secondary.

As a first consideration, let’s talk about the foundational content. PTFE, FR-4, metal, or other materials are used. In addition to the materials, the base thickness is also significant. Next, you’ll need to determine the exact dimensions of the circuit and the circuit board. The creation of PCBs relies heavily on these two elements. The through-filling, holes, and tracing are considerable after the copper thickness and the surface finish has been determined.

PCB fabrication services are likewise in high demand from buyers. Costs for materials and quality assurance inspection must get included here. PCB prices are also determined by the quantity ordered. When you order in bulk, you save money per unit. Therefore, if you place a large order, you can save money.

What is the construction procedure of a single-sided PCB?

The substrate, or foundation material, consists of insulated fiberglass with a small profile while still being as strong as a circuit board. Whether the boards are flexible or rigid PCB also determines the nature and type of the base material used. Above the substrate is a layer of copper that serves as a conductor for the board’s numerous components. Of course, the amount of copper on a board, measured in oz./sq ft, varies widely depending on the specifications you require.

On the one hand, copper foil is coverable with a soldering mask layer. The layer’s primary function is to insulate the copper foil, preventing conduction in the event of accidental contact with a conductive material. However, a silkscreen layer sits above all the other layers, and its primary function is to add symbols and characters on the board for easier readability and comprehension.

Comments are closed