Printed Circuit Board (PCB) materials are one of the important components that aid in the designing and production of printed circuit boards. You want to get the type that does not only solidify the design of the circuit board but also makes it easier for the manufacturer to design the same.

There are many types of Printed Circuit Board (PCB) materials out there. With the variety of options, you may a bit confused about the material that will perfectly fit into the design you expect on your circuit board.

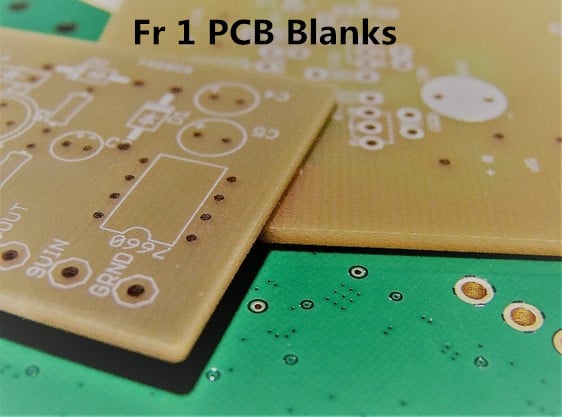

We are pleased to let you know that the FR1 PCB material is one of the best. You are also lucky to be reading this guide because you will learn all you need to know about designing a Printed Circuit Board (PCB) using the FR1 PCB material.

What Is FR1 PCB?

The first thing we must do is to define or explain what the FR1 PCB material is and does. With that knowledge, you can conveniently map out the strategies that will enhance the use of the FR1 PCB material on your next circuit board.

The FR1 PCB or Flame Retardant 1 PCB is a Synthetic Resin Bonded paper that is made up of phenol-formaldehyde resin. It is commonly used for the manufacturing of Printed Circuit Boards (PCBs). Worthy of mention is that the FR1 material is also used as PCB Laminates with a glass transition temperature that ranges between 120 and 130 degrees.

Worthy of mention is that the FR1 PCB is classified into different types. The common types are Non-Hydrophobic, Standard, and Halogen Free.

FR1 PCB and FR2 PCB

More often than not, the FR1 PCB material has been compared to the FR2 PCB. Of course, the comparison isn’t out of place considering that there are some similarities and differences between the two.

Talking about the similarities, the FR1 PCB has one characteristic with the FR2 PCB, and that is the design of phenol compounds and paper. The other similarity between the two is that they are both used for manufacturing single layer PCBs.

The major difference between the FR1 PCB material and the FR2 PCB material is the glass transition temperature. While the FR2 PCB has a glass transition temperature of 105 degrees, the FR1 PCB’s can be as high as 130 degrees.

Use Cases

There are special designations where the FR1 PCB can be used. We want you to understand that so you wouldn’t bug your PCB manufacturers with requests that might not be granted.

The primary use case of the FR1 PCB material is for 1-layer PCBs, otherwise called the Single Layer PCBs. The reason for that is that FR1 PCB cannot successfully pass through holes.

However, if you are looking at designing multiple circuit boards, it makes sense that you explore other options. The FR3 PCB material is completely out of the equation because it doesn’t offer much of what is needed. Rather, the FR4 PCB material is the best because it is versatile with the designation as a multi-layer PCB. It implies that the FR4 PCB material can conveniently aid in the design of single layers and multi-layer Printed Circuit Boards (PCBs).

Designing of PCB Substrates

PCB Substrates are an important addition to any circuit board. Because of the impressive roles they play on the board, they must be considered at all times when PCBs are been manufactured.

For that reason, the other use case or application of the FR1 PCB material is in the designing of PCB Substrates. What the material does here is that it aids in the manufacturing of PCB Substrates.

For the records, PCB Substrates is a flat board where the traces and components of the circuit board are attached.

Low-Cost Applications

The other use case or application of the FR1 PCB is in the manufacturing of electronics that don’t cost much.

This is mainly because the FR1 PCB materials are affordable and the designing procedures are simplified.

Features of FR1 PCB

Are you wondering about the features and characteristics of the FR1 PCB? There are many of them, and we will like you to be aware of those.

Below are the details of the features and properties of the FR1 PCB:

Durability

The durability of the FR1 PCB isn’t in doubt because it is highly durable. So, if you have been looking for a PCB material that can thrive despite the pressure and load it carries, the FR1 PCB material is the one to go for.

Excellent Mechanical and Electrical Properties

The mechanical and electrical components are the other elements that can sway consumers to select a particular PCB over the others. That is exactly what we have here on the FR1 PCB.

The FR1 PCB has one of the most impressive properties as far as the electrical and mechanical components are concerned.

Aids in Electrical Insulation

Electrical insulation is of the utmost importance as far as the designing of Printed Circuit Boards (PCBs) is concerned. The other reason why companies and consumers are always ready to use the FR1 PCB material is because of the inputs in the insulation of the electrical components on the circuit board.

It must be mentioned that the FR1 PCB Laminates play a vital role in the provision of the required insulation anywhere and anytime it is required on the circuit board.

Superior Finish

How is the finish of the circuit board? The last-minute touches should not only be classy but should align with the overall design of the circuit board. In that case, the FR1 PCB Laminates’ input on the circuit board isn’t to be underestimated because of the smooth surface finish superior heat resistance that it provides the board.

Mechanical Processing

If there is any feature that makes the FR1 PCB to stand out, it is the great mechanical processing capabilities.

In this case, the mechanical processing capabilities of the FR1 PCB are evident in the miling and punching that help the circuit board to withstand the mechanical pressure that may come from the board.

FR1 PCB and Other PCB Materials

There is no doubt that the FR1 PCB material is one of the best when it comes to low-end consumer electronics production. Yet, that doesn’t mean that it is the only PCB material that is used.

Indeed, there are some limitations to what the FR1 PCB can do. That is why the other PCB materials have geared up to take over the stage with the amazing properties that they have.

To that end, the limitations and lapses that are tenable on FR1 PCB are some of the reasons why the likes of the FR4 PCB material are becoming popular. Undoubtedly, the FR4 PCB material has many remarkable features that have since made it the favorite of many consumers.

It is in light of it that we will highlight the reasons why the FR4 PCB material is an option to consider if you aren’t looking to use the FR1 PCB.

What Is FR4 PCB Material?

The Flame Retardant 4 (FR4) PCB material is the type that offers different options as far as PCB design and manufacturing is concerned. It is a glass fiber epoxy laminate that is mostly used after the duo of the FR1 PCB and the FR2 PCB materials have been used. Hence, it wouldn’t be out of place to posit that the FR4 PCB material may be considered when you have tried and confirmed that the FR1 PCB didn’t give the outcome you expected.

Why the FR4 PCB Is Better Than the FR1 PCB

You don’t have to look farther when it comes to the use of the FR4 PCB material. As mentioned earlier, it is an option worth considering after FR1 PCB and FR2 PCB have been considered as base materials.

1. Variety of Applications

The first reason why the FR4 PCB material is one of the best out there is because of the many use cases. You wouldn’t be limited to the use of a mono or single layer PCB as is the case when using the FR1 PCB.

The major reason why companies are pleased with the FR4 PCB is because of the adaptability to work in many situations and configurations. For example, the FR4 PCB material can be used for the designing and manufacturing of different types of Printed Circuit Boards (PCBs).

From the one-layer to the multilayer circuit boards, the FR4 PCB has all it takes to provide what is needed.

2. Material Composition

Worthy of mention is that the material used in the design and manufacture of a Printed Circuit Board (PCB) has a lot to do with the outcome. That informs the reason why many consumers are always looking forward to using the FR4 PCB.

That is not to say that the FR1 PCB material isn’t any good. Instead, it has some great potential to offer in the enhancement of the circuit board.

Nevertheless, the FR4 PCB seems to have the upper hand with the glass fiber epoxy laminate material.

Therefore, the material composition or the type of materials that a PCB has is one of the veritable factors that can influence buying decisions.

3. Wide Use

If there is any factor that can sway companies and consumers to prefer one PCB material to the other, it is a wide acceptance. This is because the general acceptance indicates that the PCB material in question has many potentials and can further improve the functionalities of the circuit board.

Since that is the case, the FR4 PCB is in a better position when compared to the FR4 PCB material. That is because it has wide acceptance, especially in China where it is massively used.

4. Cost Factor

By and large, the cost or the amount it will cost to design a PCB is another element that must be considered. Of course, both the FR1 PCB and the FR4 PCB have their quotations. It all depends on what you are looking for to get on the circuit board you want to be designed.

Despite that, it is obvious that the FR1 PCB is taking the upper hand in this case. It is popular because of the low-end production of circuit boards. So, if you are looking to save some money without having to compromise on quality, the FR1 PCB is the circuit board you can rely on.

5. Suitability for Through-Hole Technology

Through-Hole Technology is one of the elements that are in place for the designing and production of Printed Circuit Boards (PCBs). Of course, the reason for that is that it offers better precision that bolsters the designing of the circuit board.

Also, there is a need to consider the type of PCB material that will work best for the production of circuit boards. The suitability in terms of Through-Hole Technology is one reason why the FR4 PCB is ideal. The reason is not far-fetched from the fact that the FR4 PCB material enables the components to be soldered to the pads at the other side of the board.

Why You Should Consider Using the FR1 PCB Material

The differences between the FR1 PCB material and the FR4 PCB material notwithstanding, we have uncovered some of the benefits of the former.

Indeed, there are many reasons why you must consider using the FR1 PCB material for the next circuit board you want to design.

Below are some of the reasons why you should do that:

Simplified Design

When using the FR1 PCB material, you already have in mind what you expect. Because this type of PCB material is commonly used when manufacturing single-layer circuit boards, we don’t doubt that you will use for your single-sided PCBs.

That way, you wouldn’t have to bother about the design not coming out as expected because of the mistakes that may be made if the multilayer variant was to be used.

Pricing

The price or the cost of manufacturing the FR1 PCB material is also affordable. That is partly because of the mono design and mainly because of the simplified design and manufacturing processes.

Final Words

There is no doubt that the FR1 PCB material is one of the best materials that can be used to design and manufacture the type of single layer Printed Circuit Board (PCB) you want.

The differences between it and the FR4 PCB material notwithstanding, you are sure that the FR1 PCB material will offer you the anticipated design on your one-layer circuit board.

When you are ready to design one, look for the best PCB manufacturers to handle the design.

Comments are closed