Quality printed circuit board (PCB) manufacturing is a crucial component of modern electronics production. PCBs are used in a wide range of devices, from smartphones and laptops to medical equipment and aerospace technology. As such, the quality of these boards can have a significant impact on the performance, safety, and reliability of the final product.

Choosing a reliable and high-quality PCB manufacturer is essential for any business that requires these components. A reliable manufacturer can provide consistent quality, timely delivery, and cost-effective solutions that meet the specific needs of the customer. With the increasing demand for electronics and the growing complexity of these devices, the importance of quality PCB manufacturing has never been greater.

Factors to Consider When Choosing a Quality PCB Manufacturer

When it comes to choosing a quality PCB manufacturer, there are several factors that you need to consider. In this section, we will discuss the most important factors that you should keep in mind before making a decision.

Experience and Expertise

One of the most important factors to consider when choosing a quality PCB manufacturer is their experience and expertise in the field. You should look for a manufacturer that has been in business for a considerable amount of time and has a proven track record of delivering high-quality PCBs.

Additionally, you should also consider the expertise of the manufacturer. Look for a manufacturer that has experience in manufacturing PCBs for your specific industry or application. This will ensure that they have the necessary knowledge and expertise to meet your specific requirements.

Quality Control and Testing

Another important factor to consider when choosing a quality PCB manufacturer is their quality control and testing processes. Look for a manufacturer that has a robust quality control process in place to ensure that each PCB meets the required specifications.

Additionally, you should also consider the testing processes that the manufacturer uses. Look for a manufacturer that uses advanced testing equipment and techniques to ensure that each PCB is thoroughly tested before it is delivered to you.

Certifications and Standards Compliance

Finally, you should also consider the certifications and standards compliance of the PCB manufacturer. Look for a manufacturer that is certified by industry-standard organizations such as ISO or UL. This will ensure that the manufacturer follows strict quality standards and processes.

Additionally, you should also consider the compliance of the manufacturer with other industry-specific standards such as RoHS or REACH. This will ensure that the PCBs are environmentally friendly and comply with the necessary regulations.

In conclusion, choosing a quality PCB manufacturer requires careful consideration of several factors. By keeping in mind the factors discussed in this section, you can ensure that you choose a manufacturer that delivers high-quality PCBs that meet your specific requirements.

Benefits of Choosing a Quality PCB Manufacturer

When it comes to PCB manufacturing, quality should always be a top priority. Choosing a quality PCB manufacturer can provide numerous benefits that can help improve the overall performance, reliability, and longevity of your electronic devices. Here are some of the key benefits of choosing a quality PCB manufacturer:

Reliability and Consistency

One of the main benefits of choosing a quality PCB manufacturer is the reliability and consistency of their products. Quality manufacturers use high-quality materials and advanced manufacturing processes to ensure that their PCBs are built to last. This means that you can expect your PCBs to function properly and consistently over time, even in harsh environments.

Cost Savings in the Long Run

While quality PCBs may come with a higher upfront cost, they can actually save you money in the long run. This is because quality PCBs are less likely to fail or malfunction, which can lead to costly repairs and replacements. Additionally, quality PCBs often require less maintenance and upkeep, which can also help save you money over time.

Access to Advanced Technology and Equipment

Another benefit of choosing a quality PCB manufacturer is access to advanced technology and equipment. Quality manufacturers invest in the latest technology and equipment to ensure that their PCBs are manufactured to the highest standards. This means that you can take advantage of the latest advancements in PCB technology, such as smaller form factors, higher component densities, and improved performance.

In conclusion, choosing a quality PCB manufacturer can provide numerous benefits that can help improve the performance, reliability, and longevity of your electronic devices. By prioritizing quality, you can ensure that your PCBs are built to last and provide the best possible performance for your specific application.

How to Identify a Quality PCB Manufacturer

When it comes to choosing a PCB manufacturer, quality is of utmost importance. Here are some key factors to consider when identifying a quality PCB manufacturer.

Online Research

One of the first steps in identifying a quality PCB manufacturer is to conduct online research. Look for manufacturers that have a strong online presence, including a well-designed website and active social media accounts. Check their website for certifications, such as ISO 9001, which indicates that the manufacturer has a quality management system in place.

Reviews and Recommendations

Another important factor to consider is reviews and recommendations from other customers. Look for reviews on third-party websites, such as Trustpilot or Google Reviews, to get an idea of the manufacturer’s reputation. Additionally, ask for recommendations from industry colleagues or other businesses that have worked with PCB manufacturers in the past.

Site Visits

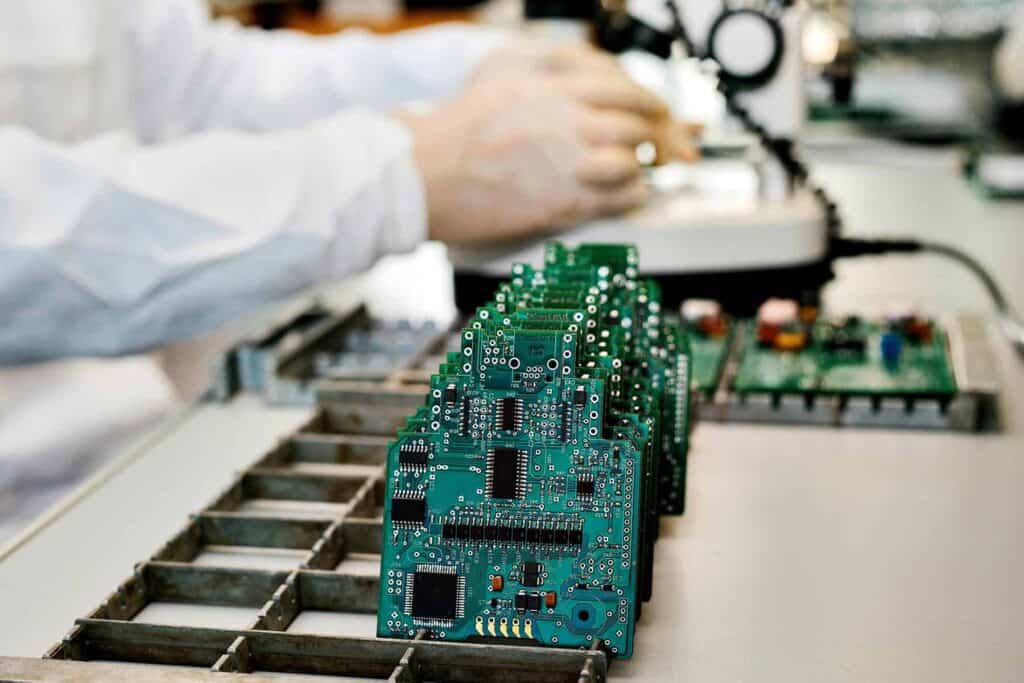

Once you have narrowed down your list of potential PCB manufacturers, consider scheduling a site visit. This will allow you to see the manufacturer’s facilities and equipment firsthand, as well as meet with their team. Look for a manufacturer that has a clean and organized facility, as well as modern equipment that is well-maintained.

Audits

Finally, consider conducting an audit of the manufacturer’s quality control processes. This can be done either by an internal team or by a third-party auditor. Look for a manufacturer that has a robust quality control process in place, including testing and inspection at every stage of production.

By considering these factors, you can identify a quality PCB manufacturer that will meet your needs and provide you with high-quality products.

Conclusion

In conclusion, finding a quality PCB manufacturer is crucial for the success of any electronic project. It is essential to consider several factors before choosing a manufacturer, such as their experience, reputation, and quality control measures.

After researching and analyzing the top PCB manufacturers in the market, we have identified the following companies as some of the best:

- JLCPCB

- PCBWay

- Advanced Circuits

- Beta Layout

- Sierra Circuits

These manufacturers have a proven track record of producing high-quality PCBs, offering competitive prices, and providing excellent customer support. They also have a wide range of PCB fabrication and assembly services, ensuring that all customer needs are met.

When selecting a PCB manufacturer, it is crucial to prioritize quality over price. While some manufacturers may offer lower prices, they may not meet the required quality standards, resulting in faulty or non-functional PCBs. It is always better to invest in a reputable manufacturer that guarantees quality and reliability.

In conclusion, by selecting a quality PCB manufacturer, you can ensure the success of your electronic project and save time and money in the long run.

Comments are closed