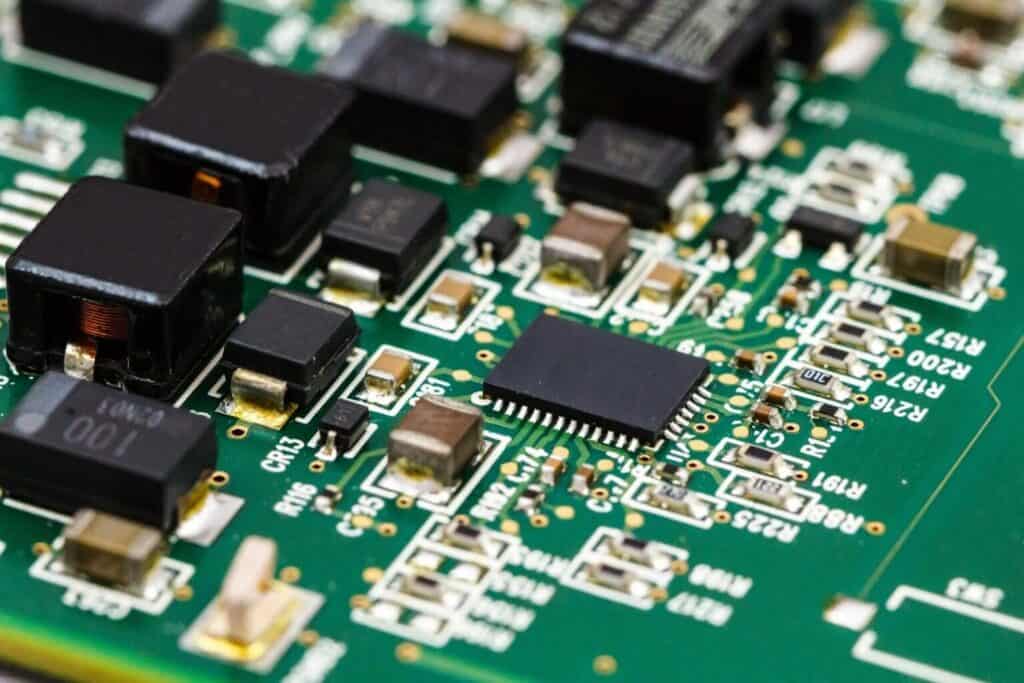

PCB circuit board assembly is a crucial process in the manufacturing of electronic devices. It involves the assembly of electronic components onto a printed circuit board (PCB) to create a functional electronic device. The assembly process is complex and requires precision and attention to detail to ensure that the final product meets the required specifications.

The PCB circuit board assembly process involves several stages, including component placement, soldering, and testing. During the component placement stage, electronic components are placed onto the PCB according to a pre-determined layout. This requires precision and accuracy to ensure that the components are placed in the correct location and orientation. The soldering stage involves the attachment of the components to the PCB using soldering techniques such as surface mount technology (SMT) or through-hole technology (THT). Finally, the assembled PCB is tested to ensure that it meets the required specifications and functions as intended.

Understanding PCB Circuit Board Assembly

What is PCB Circuit Board Assembly?

PCB (Printed Circuit Board) assembly is the process of attaching electronic components to a PCB. This process is crucial in the production of electronic devices. The PCB serves as a platform for the components and provides a pathway for electrical signals to travel between them.

The assembly process involves placing components on the PCB, soldering them in place, and testing the final product to ensure it functions as intended. PCB assembly can be done manually or using automated machines, depending on the complexity of the board and the volume of production.

Why is PCB Circuit Board Assembly Important?

PCB assembly is a critical step in the manufacturing of electronic devices. The quality and reliability of the final product depend on the accuracy and precision of the assembly process. Poorly assembled PCBs can result in malfunctioning devices, leading to costly repairs and recalls.

Additionally, PCB assembly plays a significant role in the performance of the electronic device. The speed, power consumption, and overall efficiency of the device can be affected by the quality of the assembly process.

Types of PCB Circuit Board Assembly

There are several types of PCB assembly methods, including:

-

Through-Hole Assembly: This method involves inserting components into pre-drilled holes on the PCB and soldering them in place. This method is commonly used for larger components and offers a strong mechanical connection.

-

Surface Mount Technology (SMT) Assembly: This method involves attaching components to the surface of the PCB using solder paste and a reflow oven. SMT assembly is faster and more cost-effective than through-hole assembly, but it requires more precision and expertise.

-

Mixed Technology Assembly: This method combines both through-hole and SMT assembly methods, allowing for a wider range of components to be used in the assembly process.

In conclusion, understanding the PCB circuit board assembly process is crucial for the production of high-quality electronic devices. The accuracy and precision of the assembly process can impact the performance and reliability of the final product. By choosing the appropriate assembly method, manufacturers can ensure that their electronic devices meet the highest standards of quality and functionality.

PCB Circuit Board Assembly Process

Designing the PCB Circuit Board

The first step in PCB circuit board assembly is designing the board. This process involves using computer-aided design (CAD) software to create a layout of the board, including the placement of components and the routing of traces. It is important to ensure that the design meets the requirements of the circuit and that all components fit properly on the board.

Printing the PCB Circuit Board

Once the design is complete, the next step is to print the circuit board. This is typically done using a process called photoengraving, which involves printing the design onto a special film and then transferring it onto the board using light and chemicals. The board is then etched to remove any unwanted copper and the remaining traces are coated with a layer of solder mask.

Soldering Components to the PCB Circuit Board

After the board has been printed and etched, the next step is to solder the components onto the board. This involves placing the components onto the board and then heating them with a soldering iron to melt the solder and create a strong bond between the component and the board. It is important to ensure that the components are placed in the correct locations and that the solder joints are strong and secure.

Testing the PCB Circuit Board

Once the components have been soldered onto the board, the final step is to test the circuit to ensure that it is functioning properly. This involves using a variety of testing equipment, including multimeters and oscilloscopes, to measure the voltage and current flowing through the circuit and to check for any errors or malfunctions. If any issues are found, the circuit may need to be reworked or repaired before it can be used.

In conclusion, the PCB circuit board assembly process involves designing the board, printing it, soldering the components onto it, and testing it to ensure that it is functioning properly. By following these steps carefully and using the appropriate tools and equipment, it is possible to create high-quality circuit boards that meet the needs of a wide range of applications.

Factors to Consider in PCB Circuit Board Assembly

When it comes to PCB circuit board assembly, there are several factors to consider. The following sub-sections highlight some of the most important factors to keep in mind.

Cost

Cost is a crucial factor in PCB circuit board assembly. It is important to balance the cost of the assembly with the quality of the final product. Some ways to keep costs low include:

- Using cost-effective materials

- Choosing a manufacturer with competitive pricing

- Minimizing waste during the assembly process

Quality

The quality of the final product is equally important as the cost. Poor quality PCBs can lead to malfunctions, which can be costly to fix. Some ways to ensure quality in PCB circuit board assembly include:

- Working with a reputable manufacturer

- Using high-quality materials

- Conducting thorough testing before shipping the product

Speed

In some cases, speed is a critical factor in PCB circuit board assembly. Some ways to expedite the process include:

- Choosing a manufacturer with a fast turnaround time

- Using automated assembly processes

- Minimizing the number of steps in the assembly process

Expertise

Expertise is a key factor in PCB circuit board assembly. Some ways to ensure expertise in the process include:

- Working with a manufacturer with a strong track record

- Choosing a manufacturer with specialized experience in the type of PCB being assembled

- Conducting thorough research before selecting a manufacturer

PCB Circuit Board Assembly Techniques

There are several techniques used for PCB circuit board assembly, including through-hole technology, surface mount technology, and mixed technology.

Through-Hole Technology

Through-hole technology, also known as thru-hole or through-mount technology, involves drilling holes through the PCB and inserting components into the holes. The components are then soldered onto the board from the opposite side. This technique is commonly used for components that require a strong mechanical bond or high current-carrying capacity.

Surface Mount Technology

Surface mount technology (SMT) involves attaching components to the surface of the PCB instead of drilling holes. SMT components are smaller and more compact than through-hole components, allowing for higher component density on the board. This technique is commonly used for small, lightweight, and high-speed components.

Mixed Technology

Mixed technology involves using both through-hole and surface mount components on the same PCB. This technique is commonly used for components that require different mounting methods or for boards that require a mix of high current-carrying capacity and small, lightweight components.

In conclusion, the choice of PCB circuit board assembly technique depends on the specific requirements of the board and its components. Each technique has its advantages and disadvantages, and the selection should be made based on the board’s design, cost, and performance requirements.

PCB Circuit Board Assembly Equipment

PCB assembly requires the use of specialized equipment to ensure the efficient and reliable production of high-quality circuit boards. The following sections detail the various types of equipment used in PCB circuit board assembly.

Soldering Equipment

Soldering is a critical step in the PCB assembly process, and it requires specialized equipment to ensure the proper application of solder to the board. The most common types of soldering equipment used in PCB assembly include:

- Soldering irons: Used for manual soldering of through-hole components

- Reflow ovens: Used for automated soldering of surface mount components

- Wave soldering machines: Used for large-scale automated soldering of through-hole components

Testing Equipment

Testing is a crucial step in the PCB assembly process, as it ensures that the board is functioning correctly and meets the required specifications. The following types of testing equipment are commonly used in PCB assembly:

- Automated optical inspection (AOI) machines: Used to detect defects in the board’s surface and components

- In-circuit testing (ICT) machines: Used to test the electrical connections of the board’s components

- Functional testing machines: Used to test the board’s overall functionality

Printing Equipment

Printing is an essential step in the PCB assembly process, as it involves the application of the circuit board’s design onto a physical board. The following types of printing equipment are commonly used in PCB assembly:

- Screen printers: Used to apply solder paste to the board’s surface

- Inkjet printers: Used to apply the board’s design to the board’s surface

- Laser printers: Used to create the board’s design on a film that is then transferred to the board’s surface

In conclusion, the proper use of specialized equipment is crucial to the successful assembly of high-quality PCB circuit boards.

Conclusion

In conclusion, PCB circuit board assembly is a complex process that requires attention to detail and precision. From component placement to soldering and testing, each step plays a crucial role in ensuring the final product meets the required standards.

Throughout this article, we have explored the various aspects of PCB circuit board assembly. We have discussed the different types of PCBs, the components used, and the various techniques involved in the assembly process.

It is important to note that the success of a PCB circuit board assembly project depends on several factors, including the quality of the components used, the expertise of the assembly team, and the accuracy of the design.

Therefore, it is crucial to work with a reliable and experienced PCB assembly service provider to ensure that the final product meets the required standards. With the right partner, you can be confident that your PCB circuit board assembly project will be completed efficiently and effectively.

In conclusion, PCB circuit board assembly is a complex process that requires attention to detail and precision. It is crucial to work with a reliable and experienced partner to ensure the success of your project.

Comments are closed