Surface-mount technology, or SMT, is a special method in the PCB industry. The characteristics of this method include more efficiency in its performance. Besides, it is flexible in nature and addresses different technical problems. One main component of this method is surface-mounted devices or commonly called as SMDs. These devices are unique in their configuration. These are efficient in the production of printed circuit boards.

Such circuits would need a through-hole approach, and this is how the attachment of circuit parts is executed on the surface of boards. The developmental process of surface-mounted devices is an extensive one. There are attractive mechanical and electrical properties related to these SMDs. Another important factor is the assembly of these devices. It is important to look for premium raw materials for production.

These materials should not impact the electrical conductance that leads to open circuits. There is a special soldering paste made from a metallic powder. This paste has the ability to stick the circuit parts with each other. This renders powerful soldering of these parts. Then design development of the circuit boards is important. The soldering takes palace with the help of hot temperature to make it flawless on the whole. These attributes are important for those electronic appliances that are ideal in terms of impressive thermal resistance.

Today, the producers of electronics need impressive and efficient electronic devices and gadgets. In this aspect, the use of Surface mounted devices is widely executed in different sectors. Due to this reason, surface mount tech is a leading method that is making the production process feasible.

These devices never compromise the design of the printed circuits. There is a thin line of difference between the terms surface-mounted devices and surface-mount technology. It is important to study these terms individually to avoid any confusion and misunderstanding about these.

Let’s go further in this article and explore different sections of it regarding these both.

What is SMT?

The term SMT is a type of technology used to position the circuit parts on the surface of the circuit boards. It helps in the fine arrangement of crucial circuit parts. There were different alternative methods used by former engineers in this manner. However, the old technique was a lot time-consuming. Since SMT came into existence, it has eradicated old-fashioned methods of placing circuits at large. It is the latest method that accommodates the soldering process. It allows direct soldering, which saves time.

There is no need to penetrate the leads through boards. That can be a hefty step in this process. The technique is quick and cost-efficient. The method of surface mount tech does not eat up large space to arrange multiple counterparts on the boards. Also, it’s helpful for the procedure of miniaturization, which is a typical one for many electronic devices, to make them smaller and more portable in size. The method itself is intense.

The performance of the circuit parts being mounted should not be influenced. It is important to use sufficient solder paste during the mounting of parts on the surface of boards. It is a crucial step since an extra or less amount of solder paste can complicate the procedure for the engineers and developers.

This measure also helps even when you are using minute parts during miniaturization. The whole method is supportive of automation. Different programs can be designed to arrange corresponding parts of a circuit. The complications and potential risk of damage can be reduced dramatically for the safety of expensive and sensitive circuit boards.

The Advantages and Disadvantages of SMT

There are several benefits of this tech. The circuit parts used for this tech are mini. These are not difficult to handle while mounting them on the boards. Also, these parts can be positioned on any side of the printed circuit board. These benefits come together to make the whole process budget oriented.

It is also essential to keep the risks that come with this method. The devices that run on surface mount tech are optimum for lightness in weight and are also affordable. These are also more portable than those electronics produced from the through-hole approach. Smaller electronics are those that allow congested positioning of the circuit parts to free up more space on the circuit board.

It is not wrong to say that surface mount tech is also faster than different technologies available. There are some problems with this tech too. The fast mounting of parts is not cheaper. These electronics are also more pricey than the rest. Engineers need to be more alert and precise when it comes to mounting. Precision is important for dealing with the routing of buried and blind vias. Errors in mounting can also arise, like tombstoning.

What is SMD?

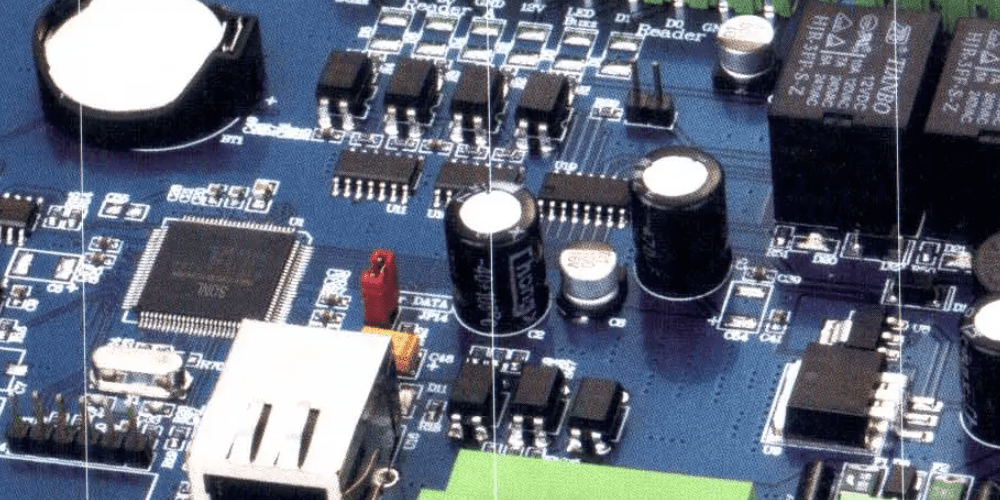

Surface Mounted Devices are the electronics that allow the arrangement and fixation of different circuit parts on the surface of a circuit board during the process of assembly. Today, users are looking for small, lightweight, fast, and reliable electronic gadgets. Special miniaturized products are now more common since they are affordable. So surface mount devices are dependable in this case. These devices have pre-made pins that go straight into the boards. It means there is no need to rely on the wiring or the use of leads.

The pins are ideal for the assembly of miniaturized parts that perform similar functions impressively. Due to this reason, it is possible to gather more and more parts by consuming less space and not compromising their quality at all. Experts believe that this process is not only quicker in execution. But also cost-efficient for the producers. It is always better to rely on the appropriate surface mount devices.

These are the foundational blocks of manufacturing a flawlessly printed circuit board later. The devices should be befitting for easy fixation. Also, these factors contribute to increasing the durability of surface mount devices.

Types of SMDs

Chip resistors: Such resistors come with three numbers on their structures that are for showing the value of resistance.

Network resistors: These are ideal for utilization in digital circuits. Also, these are in the form of packages that include many resistors with the same properties.

Capacitors: The famous ceramic capacitors that are multilayer are two. These are aluminum and tantalum capacitors.

Diode: A diode is from a group of surface mount devices. It contains a colorful ring on one of its sides.

LEDs: The LEDs come in various colors, like blue, red, and yellow.

Transistors: There are different types of transistors available. These include fuses, oscillators, and inductors.

IC: Integrated circuits are for maintaining the performance of different electronic appliances.

SMT Makes SMDs More Effective

The term surface mount tech itself is a type of mounting. At the same time, surface mount devices are those parts that are mounted. There are some regions on the printed circuit boards where these converge with each other. The whole process of surface mount tech includes one prominent step of appropriate fixation of surface mount devices on the circuit boards.

The importance of surface mount tech is crucial for the natural functioning of prototypes. There is a different type of machinery available for the surface mount tech. This enhances the performance and results of surface mount tech for different devices. There are different use cases of this tech in multiple sectors.

What is Through-Hole Mounting?

Through-hole mounting includes an arrangement of circuit parts with the help of slits present in the printed circuit boards. Through-hole was the measuring unit for the mounting of circuit parts. Over the years, the use of surface mount tech has been a crucial aspect in the progress of this industry.

The benefit of through-hole electronics is that they enhance the reliability of electronic appliances. These are for providing uninterrupted connections in the circuit. The nature of surface mount devices is that these are for attachment of the circuit parts onto the boards with the help of solder paste. These devices anchor the electronics in terms of enduring extreme climatic fluctuations. This is the process of fixing components into a circuit board. Before the invention of SMT, the through-hole was the SI unit of mounting components. The surface mount tech is also important for the development of prototypes and their use cases.

The Advantages and Disadvantages of Through-Hole Components

It’s time to discuss the pros and cons of through-hole devices. There is a majority of through-hole devices functional in this sector. Some electronics do not require different properties of printed circuit boards. These electronics are ideal for withstanding the fluctuations of heat and power during the development of prototypes.

These printed circuit boards are minute in size and are also more affordable when bulk production is required. There are firm requirements for temperature regulation. There are special leads in these devices that you must attach with the holes before the step of soldering of the copper pads present in the circuit boards. In this way, the through-hole method is safer than the other methods.

These devices are reliable for the sectors that are always enduring thermal stress produced by electronics. These devices are always bulkier than surface mount devices. It means these are heavy in weight as well. Due to more power, these are ideal for attaching to the stealthy electronics of commercial grade. These allow easy replacement as well during the development of prototypes. There are some setbacks throughout the whole method that needs complete discussion.

These problems are related to the circuit board size, costs of production, and time needed for production. The through-hole devices need more time for assembly. These need proper drilling in the board, which raises the production cost for the producers. When it comes to through-hole devices, these can only afford the soldering of one circuit part at a time. Therefore, it is better to learn about the pros and cons and also the details of through-hole and surface-mount tech devices.

Axial and Radial Lead Components

Through-hole devices have two major categories. These are either radial or axial lead circuit parts. Axial leads work with devices that are aligned straight. These include wires that exit from any direction. The producers have to use mounting procedures to fix the ends with the help of pre-made holes. This supports flawless packaging of the circuit parts.

The radial leads are for printed circuit boards and exit from these from any side of the board. Both types have their own advantages. The lead devices are important because they provide an ergonomic system for the circuit boards. Radial leads don’t need more space. These are important for the production of those circuits that work on high-density levels. Axial leads are resistors, capacitors, and uses. Radial leads include ceramic disk capacitors that are common for execution.

Combination of SMD and SMT

In the former days, engineers used to rely on minute and complicated circuit parts. Then they had to position them and solder them manually. There was no use of tech-based equipment at all. The technical machinery used at that time had its own limitations. But as technology advanced, the production of circuit boards is however identical to the former methods. But these are quicker in production and offer more precision than the older variants.

The producers would use small pieces of different metals like silver and lead. These would have to be fixed on the circuit boards to connect the circuit parts. This measure is still common for utilization.

Today, the latest gear used in the commercial sector assembles hundreds and thousands of surface mount devices in an hour. The best part about these devices is that they offer fast production of circuit boards. In this way, these take less time and space, which is another important feature of these devices for the producers.

Conclusion

Surface mount tech is a leading method for the feasibility of mounting in the PCB industry. At the same time, a through-hole is useful when it comes to bigger circuit boards. These electronics are applicable in the domains like the military. Also, SMT is useful for consumer electronic appliances like wearables and smart gadgets. In this post, you have learned about several techniques in detail, along with other important aspects.

Comments are closed