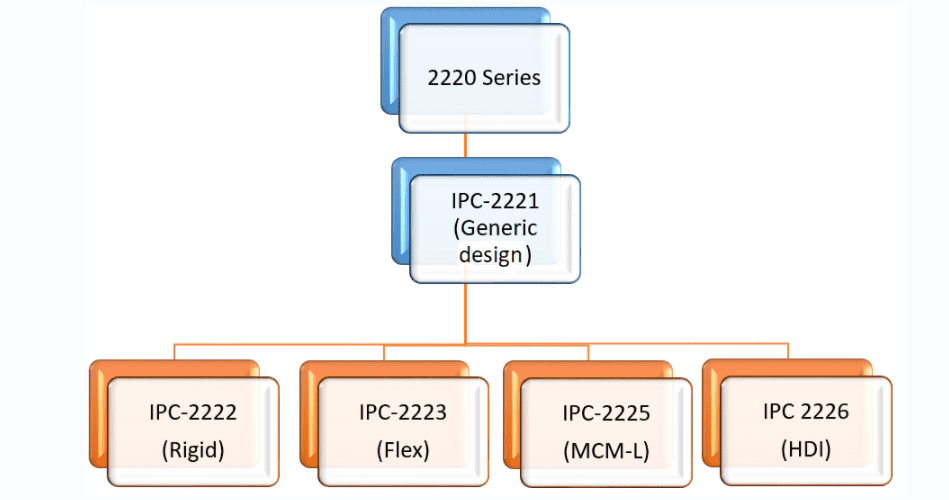

All IPC-2220 model series are built on the PC-2221 design standard. It defines the general standards for constructing PCBs, including other types of mono, dual, or multilayer mounting components or interconnecting frameworks. This standard also offers test coupon layouts for lot approval and quality conformity testing.

The IPC-2221 standard aims to enlighten manufacturers on the general requirements for the design of organic printed boards. To the extent that they can be applied to a wide range of designs that use natural materials or natural materials paired with artificial materials (glass, metal, ceramic, etc.) to form the framework for mounting and connecting electrochemical, mechanical, and electronic components. All these aspects and information of the design specifications are addressed.

A choice must be made concerning selecting product types as soon as possible. The user should receive the sectional documentation, such as IPC-2222, IPC-2223, IPC-2224, IPC-2225, IPC-2226, and IPC-2227, that offer a special focus on the chosen technology once a component mounting and connectivity technique has been chosen.

There are guidelines to follow regarding PCB fabrication, assembly, and design. Industries and organizations must establish clear standards for their operations. In each area we find ourselves, standards enable us to succeed. No matter what field you work in, it is crucial that you follow the rules that have been established.

Choosing an electrical manufacturing engineer that follows IPC requirements for PCB design and assembly is also crucial. The PCB and electrical industries have several requirements. The IPC standard, however, stands out. Additionally, every step in PCB manufacture is covered by this standard. Your electronic contract manufacturer’s capacity to adhere to IPC standards affects the usefulness and sustainability of your PCB model.

What Do You Mean By IPC Standards?

The ‘Institute for Printed Circuits”‘ is the long form of the acronym ‘IPC.’ It is the official name of the organization that creates standards for PCBs. The IPC standard is a recognized and accepted benchmark for electronic assembly, PCB design, and production. The IPC’s legal name was changed to The ‘Association Connecting Electronics Industries’ in 1998. To this day, it is still frequently referred to as IPC.

The IPC standards also set the foundation for the electronics industry’s design, assembly, inspection, and packaging standards. IPC standards govern PCBs’ fabrication, design, testing, and assembly. If PCB designers adhere to these requirements, the product will succeed, but if not, it’ll be otherwise.

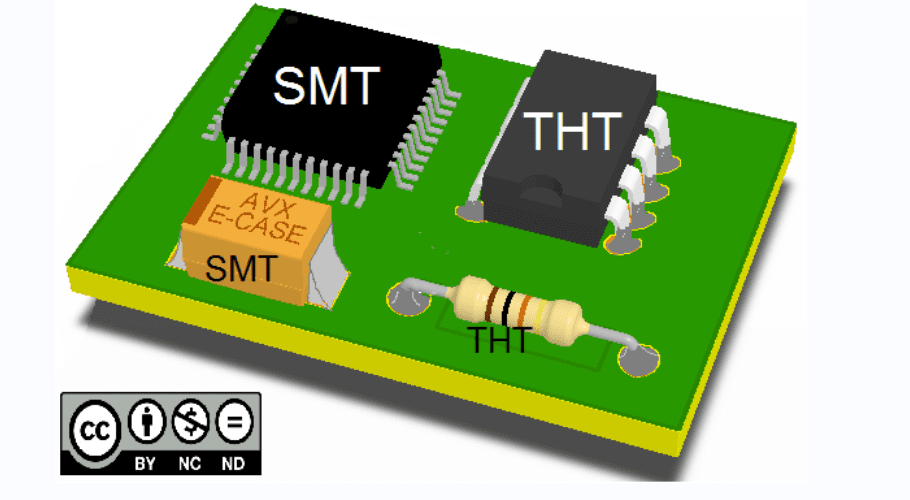

Several PCB design factors can affect the dependability and manufacturability of PCB. For example, PCB designers can assume which part of a pad THT components will fit best. Therefore, failing to design following IPC standards could lead to a lack of standardization amongst designers and manufacturers.

IPC has various standards for circuit board design. They include IPC-2221, IPC-221A, IPC-2222, and IP- 2223. These IPC standards are the criteria that the electronics sector accepts the most. IPC also creates standards for the electronics sector. Because of that, it is crucial to PCB production. Additionally, IPC standards are important for all phases of PCB fabrication.

The IPC-2221 Standard

The IPC-2221 specification/standard is a widely regarded industry standard — this aids in providing guidelines for various PCB design components. The design specifications/standards for various materials includes substrates and plating, thermal management, thermal reliefs, annular rings, testability, etc.

Additionally, more precise design standards often replace some design recommendations. For example, the IPC-6012 and IPC-6018 provide design criteria for stiff PCBs and high-frequency PCBs, respectively. Additionally, the IPC-2221 specifications for generic PCBs should be consistent with these new standards.

Furthermore, the IPC-2221 specification/standard isn’t used to evaluate manufacturing errors, productivity, or durability. In addition, the produced rigid PCBs for rigid boards must be approved using either the IPC-6012 or IPC-A-600, and some bodies are responsible for reviewing and giving this approval.

There are particular requirements for each type of board. Consider that the IPC-2221 and IPC-2222 standards, described in the former, must be consulted while designing rigid PCBs. This also holds for the multichip module, high-density interconnect (HDI), and flex. Because of this, all IPC-2221 generic standards must be applied per their specific and detailed requirements for various types of circuit boards.

The matching of the required thermal, electrical, and mechanical characteristics must be the primary emphasis of PCB designers. Furthermore, it would help if you kept an eye on the board’s reliability, pricing, and manufacturing challenges — the IPC-2221 assists in concentrating on all the factors, which is what it provides.

The IPC-2221 specification/standard also assists in addressing many board design-related concerns. It also includes the most significant requirements for design, high-voltage, clearance, and creepage. That way, designers do not have to worry about making mistakes that may affect the board’s short-term or long-term work.

Although the IPC standards are optional, using them enhances the product’s robustness, dependability, and durability. In addition, when combined with other specifications, they can lower electromagnetic pollutant concentrations and aid in passing the tests and qualifications that electronic products must pass to be sold in foreign markets (ISO, IEC, and ITU specifications and tests might be compulsory to gain access into other markets).

They help people stand out within their nation and ensure the best products are manufactured that meet the needs of the people. By drawing on others’ expertise, you can create and manufacture products more quickly and inexpensively.

Bottom Line

Keep in mind that IPC-2221 standards are optional. Clearance and creepage demands in the appropriate IEC or UL standard may become requirements that must be followed for goods subject to safety standards described in electrical and building codes. For instance, the IEC 62368-1 specification contains the pertinent safety criteria for IT and telecom appliances using battery power and AC mains.

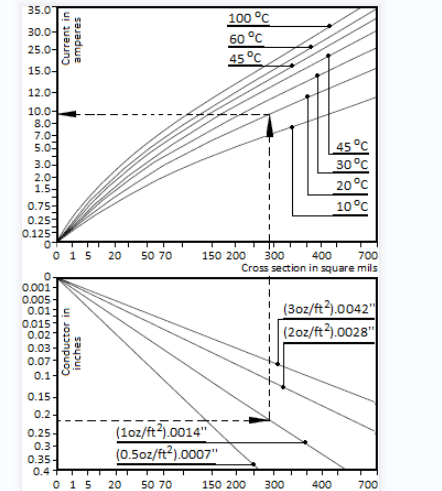

The distance required per IPC-2221B for creepage depends on the RMS voltage level, pollution degree (ranked from 1 to 3), and product group. The UL 62368-1 specification provides the meanings of the last two terms. If there are any necessary safety standards, such as IPC, IEC, or others, you must adhere to them; you can define your design criteria as rules you’re using the suitable PCB software.

Comments are closed