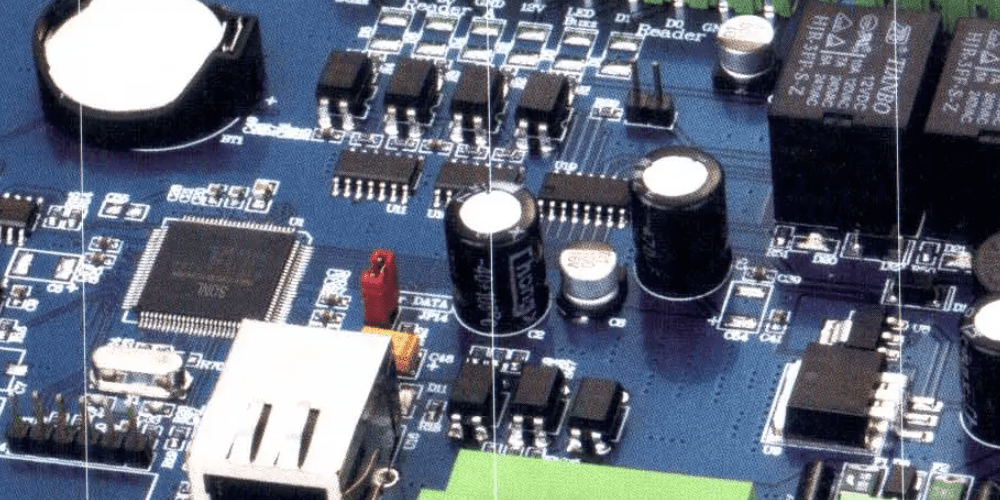

Printed circuit board (PCB) assembly is the process of connecting electronic components to a PCB to create a functional electronic circuit. PCBs are used in a wide range of electronic devices, including computers, smartphones, and medical equipment. The assembly process involves several steps, including component placement, soldering, and testing.

One of the main advantages of printed PCB assembly is its cost-effectiveness. PCBs can be produced in large quantities, which reduces the per-unit cost. Additionally, the use of automated assembly equipment reduces labor costs. This makes PCB assembly an attractive option for manufacturers looking to produce electronic devices at scale.

Another advantage of printed PCB assembly is its reliability. The use of automated equipment ensures that components are placed accurately and soldered correctly. This reduces the risk of defects and improves the overall quality of the final product. Additionally, PCBs are designed to be durable and can withstand harsh operating environments, making them a reliable choice for a wide range of applications.

What is Printed PCB Assembly?

Printed PCB Assembly (PCBA) is the process of creating a printed circuit board (PCB) by assembling electronic components on it. The PCB is a flat board made of insulating material with conductive pathways etched on it to connect different electronic components.

The process of printed PCB assembly involves several steps, including designing the PCB layout, choosing the components, soldering the components onto the board, and testing the board to ensure it functions properly.

There are two main types of printed PCB assembly: Surface Mount Technology (SMT) and Through-Hole Technology (THT). SMT involves placing the components directly onto the surface of the PCB, while THT involves inserting the components into holes drilled into the PCB and soldering them onto the other side.

Printed PCB assembly is used in a wide variety of electronic devices, from simple consumer electronics like calculators and remote controls to complex industrial machinery and medical equipment. It is a crucial part of the manufacturing process for many electronic products, as it allows for efficient and reliable assembly of electronic components onto a single board.

Advantages of Printed PCB Assembly

Cost-effective

Printed PCB assembly is a cost-effective solution for small and large scale production. It allows for the production of complex circuit designs at a lower cost compared to traditional methods. With printed PCB assembly, the cost of material, labor, and equipment is reduced, making it an ideal option for startups and businesses on a budget.

High Accuracy

Printed PCB assembly offers high accuracy and precision in the production of circuit boards. The use of computer-aided design (CAD) and computer-aided manufacturing (CAM) software ensures that the circuit designs are accurate and free from errors. The use of automated machines in the assembly process also ensures that the components are placed precisely on the board, reducing the risk of errors and improving the overall quality of the finished product.

Fast Turnaround Time

Printed PCB assembly offers a fast turnaround time, allowing for the production of circuit boards in a short amount of time. The use of automated machines in the assembly process reduces the time required for manual labor, resulting in a faster and more efficient production process. This makes printed PCB assembly an ideal option for businesses that require a quick turnaround time for their products.

In conclusion, printed PCB assembly offers several advantages over traditional methods of circuit board production. It is cost-effective, offers high accuracy, and has a fast turnaround time, making it an ideal option for businesses of all sizes.

Applications of Printed PCB Assembly

Printed PCB Assembly technology has a wide range of applications across various industries. Here are some of the most common applications of Printed PCB Assembly:

Consumer Electronics

Printed PCB Assembly is widely used in consumer electronics such as smartphones, tablets, laptops, and gaming consoles. These devices require high-performance PCBs that are compact, lightweight, and durable. Printed PCB Assembly technology allows manufacturers to produce PCBs that meet these requirements while reducing the overall cost of production.

Medical Devices

Printed PCB Assembly is also used in medical devices such as pacemakers, defibrillators, and insulin pumps. These devices require PCBs that are reliable, accurate, and safe to use. Printed PCB Assembly technology allows manufacturers to produce PCBs that meet these requirements while reducing the overall size and weight of the device.

Automotive Industry

Printed PCB Assembly is used in the automotive industry for a variety of applications. PCBs are used in engine control units, airbag systems, and navigation systems. Printed PCB Assembly technology allows manufacturers to produce PCBs that are durable, reliable, and resistant to temperature fluctuations.

In conclusion, Printed PCB Assembly technology has a wide range of applications across various industries. It allows manufacturers to produce high-performance PCBs that meet the requirements of different applications while reducing the overall cost of production.

Types of Printed PCB Assembly

Printed PCB assembly is a process of assembling electronic components onto a printed circuit board (PCB). There are different types of PCB assembly methods depending on the complexity and requirements of the electronic device. In this section, we will discuss the three main types of printed PCB assembly.

Single-Sided PCBs

Single-sided PCBs are the simplest type of PCB assembly. They consist of a single layer of conductive material, usually copper, on one side of the board. The components are placed on the same side of the board as the conductive layer. Single-sided PCBs are commonly used in low-cost electronic devices, such as calculators and remote controls.

Double-Sided PCBs

Double-sided PCBs have two layers of conductive material, one on each side of the board. The components are placed on both sides of the board, and the conductive layers are connected by vias. Double-sided PCBs are used in more complex electronic devices, such as smartphones and computers.

Multi-Layered PCBs

Multi-layered PCBs have three or more layers of conductive material, separated by insulating layers. The components are placed on multiple layers, and the conductive layers are connected by vias. Multi-layered PCBs are used in high-end electronic devices, such as aerospace and medical equipment.

In summary, the type of printed PCB assembly used depends on the complexity and requirements of the electronic device. Single-sided PCBs are the simplest and cheapest, while multi-layered PCBs are the most complex and expensive. Double-sided PCBs offer a balance between cost and complexity.

Printed PCB Assembly Process

Design

The first step in the printed PCB assembly process is designing the PCB. This involves creating a schematic of the circuit and laying out the components on the board. The design should take into account the size and shape of the board, the location of the components, and the routing of the traces.

Printing

Once the design is complete, it is time to print the PCB. This involves transferring the design onto a copper-clad board using a special printer or plotter. The board is then etched to remove the copper that is not part of the circuit, leaving behind the traces and pads.

Soldering

The final step in the printed PCB assembly process is soldering the components onto the board. This involves placing the components onto the pads and then heating the pads with a soldering iron to melt the solder and create a bond between the component and the board.

Overall, the printed PCB assembly process is a complex and precise process that requires careful attention to detail and a thorough understanding of the design and manufacturing processes involved. By following best practices and using high-quality materials and equipment, it is possible to create high-quality PCBs that meet the needs of a wide range of applications.

Common Issues with Printed PCB Assembly

Short Circuits

Short circuits happen when two or more conductive paths touch each other, causing a connection where there shouldn’t be one. This can be caused by a variety of factors, including design flaws, manufacturing errors, or damage during handling or assembly. Short circuits can lead to overheating, damage to components, and even fires.

To prevent short circuits, it’s important to carefully inspect the design and layout of the PCB before manufacturing. During assembly, it’s important to use proper techniques and tools to ensure that components are placed correctly and that there are no solder bridges or other connections where there shouldn’t be.

Open Circuits

Open circuits happen when there is a break in the conductive path, preventing electricity from flowing properly. This can be caused by a variety of factors, including manufacturing errors, damage during handling or assembly, or design flaws. Open circuits can lead to malfunctioning or non-functioning circuits.

To prevent open circuits, it’s important to carefully inspect the PCB and components before assembly, and to use proper techniques and tools during assembly to ensure that all connections are properly made. It’s also important to test the PCB after assembly to ensure that all connections are functioning properly.

Component Misalignment

Component misalignment happens when components are not placed correctly on the PCB, leading to incorrect or non-functioning circuits. This can be caused by a variety of factors, including manufacturing errors, damage during handling or assembly, or design flaws.

To prevent component misalignment, it’s important to carefully inspect the PCB and components before assembly, and to use proper techniques and tools during assembly to ensure that all components are placed correctly. It’s also important to test the PCB after assembly to ensure that all components are functioning properly.

In conclusion, these are some of the most common issues that can arise with printed PCB assembly. By carefully inspecting the design and layout of the PCB, using proper techniques and tools during assembly, and testing the PCB after assembly, many of these issues can be prevented.

Conclusion

Printed circuit board (PCB) assembly is a crucial process in electronics manufacturing. It involves the assembly of electronic components onto a printed circuit board. The process involves several steps, including soldering, inspection, testing, and packaging.

The use of printed circuit board assembly has several benefits. It ensures that the electronic components are securely mounted onto the board, reducing the risk of damage or failure. It also makes the manufacturing process more efficient and cost-effective.

One of the most significant advantages of printed circuit board assembly is its flexibility. PCBs can be designed to meet specific requirements, making them suitable for a wide range of applications. Additionally, they can be easily modified or upgraded, making them ideal for prototyping and product development.

Overall, printed circuit board assembly is a critical process that plays a significant role in electronics manufacturing. It ensures that electronic components are securely mounted onto the board, making them reliable and durable. With the continued development of technology, we can expect to see further advancements in PCB assembly in the future.

Comments are closed