Soldering is an essential technique used in the assembly of electronic circuit boards. It involves joining two pieces of metal together using a low-melting-point alloy called solder. The process creates a permanent bond that allows for the transfer of electrical signals and power between components.

Soldering is a precise and delicate process that requires attention to detail and a steady hand. It involves heating the metal pieces to be joined, applying the solder, and then allowing it to cool and harden. The result is a strong and reliable connection that is essential for the proper functioning of electronic devices.

Whether you are a professional electronics technician or a hobbyist, understanding the basics of soldering is essential for working with electronic circuit boards. In this article, we will explore the fundamentals of soldering, including the tools and materials required, the techniques used, and the common mistakes to avoid. By the end of this article, you will have a solid understanding of how to solder electronic circuit boards and be able to tackle your own projects with confidence.

Understanding Soldering

What is Soldering?

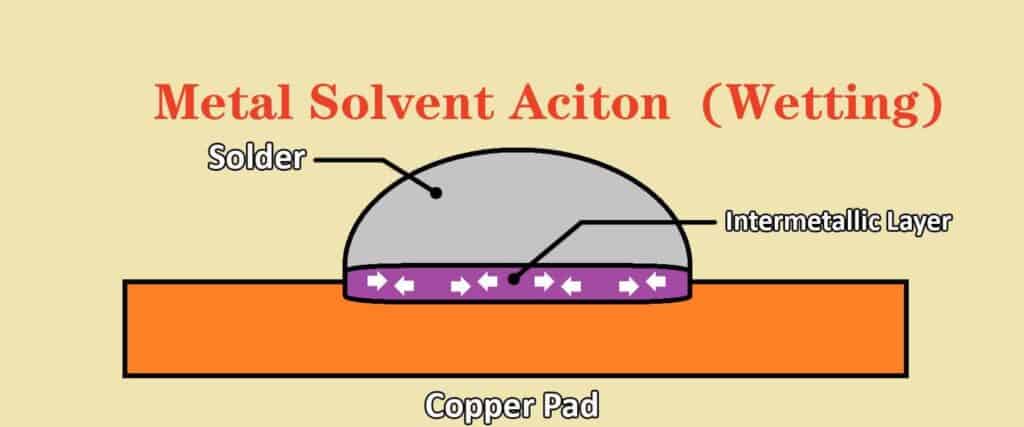

Soldering is a process of joining two metal surfaces together by melting a filler metal, known as solder, and then cooling it to form a permanent bond. It is commonly used in electronic circuit board assembly, plumbing, and jewelry making. The soldering process requires a heat source, a soldering iron or gun, and a flux to remove any impurities from the metal surfaces to be joined.

Types of Soldering

There are several types of soldering techniques, including:

- Through-hole soldering: This technique involves inserting the leads of electronic components through holes in the circuit board and then soldering them to the copper traces on the other side of the board.

- Surface mount soldering: This technique involves soldering electronic components directly onto the surface of the circuit board.

- Reflow soldering: This technique involves applying solder paste to the circuit board and then heating it in a reflow oven to melt the solder and create a permanent bond.

Soldering Tools

To perform soldering, you will need the following tools:

- Soldering iron or gun: This tool provides the heat needed to melt the solder. A soldering iron is a pen-shaped tool with a pointed tip, while a soldering gun is a larger tool that looks like a pistol.

- Solder: This is the filler metal that is melted to create the bond between the metal surfaces.

- Flux: This is a chemical that is used to remove any impurities from the metal surfaces to be joined and to promote the flow of the solder.

- Soldering station: This is a tool that includes a soldering iron or gun, a stand to hold the tool when not in use, and a temperature control to regulate the heat of the tool.

In conclusion, understanding soldering is essential for anyone who wants to assemble electronic circuit boards. By knowing the basics of what soldering is, the different types of soldering techniques, and the necessary tools, you can create strong and reliable connections between electronic components.

Preparing for Soldering

Cleaning the Circuit Board

Before starting to solder, it is important to clean the circuit board thoroughly. Any dust, debris, or oxidation on the board can prevent the solder from adhering properly, leading to weak or unreliable connections. Use a soft-bristled brush or a compressed air canister to remove any loose particles, and then wipe the board with a lint-free cloth moistened with isopropyl alcohol. Avoid using water or solvents that can leave residue or damage the components.

Selecting the Right Soldering Iron

Choosing the right soldering iron is crucial for achieving good results. The iron should have a wattage appropriate for the size and complexity of the circuit board, as well as a temperature control feature that allows you to adjust the heat according to the type of solder and components you are using. A soldering iron with a thin, pointed tip is ideal for precision work and tight spaces, while a chisel tip is better for larger areas and thicker wires.

Choosing the Right Solder

There are several types of solder available, each with its own characteristics and recommended applications. Lead-free solder is now the standard for most electronics, as it is safer for the environment and human health. Tin-lead solder is still used in some cases, but it requires more caution and ventilation. The thickness of the solder wire should match the size of the components and the amount of heat applied. Rosin-core solder is a popular choice for its flux core that helps the solder flow and bond better.

In summary, preparing for soldering involves cleaning the circuit board, selecting the right soldering iron, and choosing the right solder. By following these steps, you can ensure a clean, strong, and reliable connection between the components.

Soldering Techniques

Tinning the Soldering Iron Tip

Before beginning any soldering project, it is important to ensure that the soldering iron tip is properly tinned. This involves applying a small amount of solder to the tip of the iron, which helps to improve heat transfer and make it easier to melt solder onto the circuit board. To tin the tip, follow these steps:

- Turn on the soldering iron and allow it to heat up.

- Clean the tip of the iron with a damp sponge or cloth to remove any debris or oxidation.

- Apply a small amount of solder to the tip by touching the solder wire to the iron and allowing it to melt and spread evenly across the surface.

- Wipe off any excess solder with a damp sponge or cloth.

Applying Solder to the Circuit Board

When soldering components onto a circuit board, it is important to use the correct technique to ensure a strong and reliable connection. Follow these steps to apply solder to the circuit board:

- Heat the joint with the soldering iron for a few seconds to ensure it is hot enough to melt the solder.

- Touch the tip of the solder wire to the joint and allow it to melt and flow evenly across the joint.

- Remove the solder wire and continue to heat the joint for a few seconds to ensure the solder has properly flowed and solidified.

- Allow the joint to cool before moving on to the next one.

Desoldering Techniques

Occasionally, it may be necessary to remove a component or repair a faulty joint by desoldering the existing solder. Follow these steps to desolder a joint:

- Heat the joint with the soldering iron until the solder melts.

- Use a desoldering pump or wick to remove the melted solder from the joint.

- Repeat as necessary until all of the solder has been removed.

- Clean the joint with a damp sponge or cloth before soldering a new component in place.

Remember to always work in a well-ventilated area and use caution when working with hot soldering irons and molten solder. With these techniques, you can successfully solder electronic circuit boards with confidence.

Common Mistakes to Avoid

Overheating the Circuit Board

Overheating the circuit board can cause serious damage to the components and the board itself. It can also create solder bridges, where the solder connects two or more pins that should not be connected. To avoid overheating the circuit board, use a soldering iron with the appropriate wattage for your project. Make sure to also use a soldering iron with a temperature control feature. This will allow you to set the temperature to the appropriate level for your project and avoid overheating.

Using Too Much Solder

Using too much solder can create solder bridges, which can cause short circuits. It can also make it difficult to work with the board and components. To avoid using too much solder, use a soldering iron with a fine tip. This will allow you to apply the solder precisely where it is needed. Also, avoid using too much pressure when applying the solder. Instead, let the solder flow naturally onto the joint.

Not Using Enough Flux

Flux is a chemical that helps the solder flow onto the joint and create a strong bond. Not using enough flux can make it difficult to create a strong bond between the components and the board. To avoid this mistake, make sure to apply flux to the joint before applying the solder. Use a flux pen or apply a small amount of flux to the joint with a brush.

In conclusion, soldering electronic circuit boards can be a tricky process. By avoiding these common mistakes, you can ensure that your project is successful and that your circuit board and components are not damaged.

Advanced Soldering Techniques

When it comes to soldering electronic circuit boards, there are a few techniques that can take your skills to the next level. Here are some advanced soldering techniques that every electronics enthusiast should know:

Surface Mount Technology

Surface mount technology (SMT) is a popular method of soldering electronic components to a circuit board. With SMT, the components are mounted directly onto the surface of the board, rather than being inserted through holes. This allows for smaller and more compact designs.

When soldering SMT components, it’s important to use a fine-tipped soldering iron and a steady hand. It’s also important to use a good quality flux to ensure a strong bond between the component and the board.

Through-Hole Soldering

Through-hole soldering is an older method of soldering electronic components. With this technique, the components are inserted through holes in the circuit board and then soldered in place. While through-hole soldering is less common than SMT, it’s still used in some applications.

When soldering through-hole components, it’s important to use the correct size of soldering iron tip. A tip that is too small or too large can make it difficult to get a good solder joint. It’s also important to use the correct amount of solder – too little and the joint will be weak, too much and it can cause problems with the component.

BGA Soldering

Ball grid array (BGA) soldering is a technique used to solder components with a large number of pins. With BGA, the pins are arranged in a grid pattern and are soldered to the board using tiny balls of solder.

BGA soldering requires a lot of skill and experience, as it’s easy to make mistakes that can damage the component or the board. It’s important to use a good quality flux and to ensure that the component is properly aligned before soldering.

In conclusion, these advanced soldering techniques can take your skills to the next level and help you to create more complex and sophisticated electronic designs. With practice and patience, you can become an expert at soldering electronic components.

Troubleshooting Soldering Problems

Cold Joints

Cold joints are a common problem that can occur during the soldering process. A cold joint is a joint that has not been heated enough, resulting in a weak bond between the components and the board. This can cause the joint to break or become loose over time, leading to malfunctioning of the circuit.

To avoid cold joints, ensure that the soldering iron is heated to the correct temperature before starting the soldering process. Use a temperature-controlled soldering iron to maintain the correct temperature throughout the process. Also, make sure that the components and board are clean and free of any dirt or debris that can interfere with the soldering process.

Solder Bridges

Solder bridges occur when two or more adjacent solder joints are connected by a small amount of solder, creating a short circuit between the components. This can cause the circuit to malfunction or fail completely.

To avoid solder bridges, use the correct amount of solder for each joint and avoid applying too much pressure to the soldering iron. Also, use a solder wick or a desoldering pump to remove any excess solder from the joints.

Solder Splashes

Solder splashes occur when excess solder is applied to the joint, resulting in a blob of solder on the board. This can cause the joint to become weak or break over time, leading to malfunctioning of the circuit.

To avoid solder splashes, use the correct amount of solder for each joint and avoid applying too much pressure to the soldering iron. Also, use a solder wick or a desoldering pump to remove any excess solder from the joints.

In conclusion, troubleshooting soldering problems is an important part of the soldering process. By following these tips and techniques, you can avoid common soldering problems and ensure the proper functioning of your electronic circuit boards.

Conclusion

Soldering electronic circuit boards is a crucial skill for anyone interested in electronics or DIY projects. Through this process, one can connect electronic components to create functional circuits. In this article, we have discussed the basics of soldering, including the types of soldering techniques, tools, and materials required for a successful soldering process.

With the proper tools and techniques, anyone can learn to solder electronic circuit boards. However, it is important to understand that soldering requires patience, practice, and attention to detail. Even a small mistake can result in a non-functional circuit or even damage to the components.

When soldering, it is important to choose the appropriate soldering technique for the specific circuit board and components. The right technique can help ensure a strong, reliable connection between components. Additionally, using high-quality soldering tools and materials can make the process easier and more efficient.

Overall, soldering electronic circuit boards is an essential skill for anyone interested in electronics or DIY projects. With practice and attention to detail, anyone can learn to solder and create functional circuits.

Comments are closed