Printed Circuit Board (PCB) designs are not to be rushed. As a consumer, one of the best ways to get started is to request a PCB assembly instant quote. The instantaneous of the quotation means that you will have it in the shortest time possible.

We understand that for some reasons, you don’t know how to start the process. You are wondering about what the cost will likely be, as well as the best manufacturer to contact for the job.

You can lay your mind to rest, knowing that we got you covered. In this article, we aim to clarify the following:

- Why you need PCB assembly instant quote

- The best manufacturers to contact for the design

- The different types of PCB quotations you can request

- What the manufacturer expects of you before starting the design

- Factors that would likely influence the cost of the PCB assembly instant quote

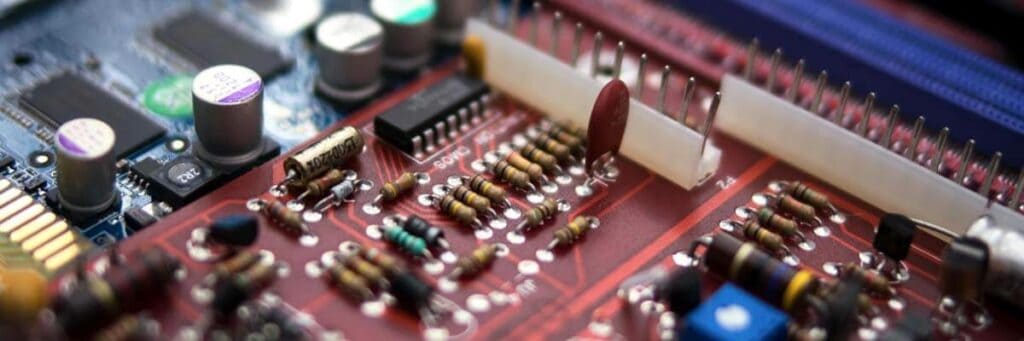

PCB Quotation Definition

A quotation is simply an estimated price of an “idea of what the final cost of a product” or in this case – the PCB design would be. Thus, the PCB assembly instant quote helps you to know what it would cost to get the prototype of the circuit board or the final design readied.

With this quotation, you can then adjust your budget upwards or make necessary modifications to enable the manufacturer work with the amount you budgeted for the project.

Requesting the quote should be the first thing you do after getting the design files readied for the circuit board.

With the above in mind, let us dive in to talk about some of the major reasons why you need to request a quotation for any PCB design.

1. You Will Know the Cost

This is the major reason for requesting PCB assembly instant quote. You want to have an idea of what it would cost to get the job done. Most often, the quotation includes the cost of the components, the workmanship and the shipping (if the manufacturer is handling that).

2. Who Handles the Component Sourcing?

With the PCB assembly instant quote, you will also know the person in-charge of sourcing the components. If you would like to handle that, it is best to inform the manufacturer on time.

However, it is always advisable to leave the entire process in the hands of the Printed Circuit Board (PCB) manufacturer.

3. Order Requirements

The quotation also lets you into the Minimum Order Quantity (MOQ), that is, the limited numbers of PCBs you can request assembled.

4. IP Protection

One disadvantage of requesting a quotation is that the important information is revealed in the process. In the PCB market, information is key. If your competitor gets an idea of the type of circuit board you want to beat, the company could beat you to it.

However, one advantage of requesting a PCB assembly instant quote is that the order is mostly done online. That way, you can be sure of placing the order and not having an infringement on the Intellectual Property (IP).

At RayPCB, we use the most secure technology to safeguard your circuit board’s Intellectual Property (IP).

What is the Best Way to Request PCB Assembly Instant Quote?

Before, consumers had to send emails and if they are close to the manufacturer, make a walk-in delivery of the circuit board schematics.

But all that has changed since most PCB manufacturers took to using the Internet to streamline the process. You can now order for your PCBs online and even get the PCB assembly instant quote from the manufacturer’s website.

This does not only reduce the time spent going back-and-forth with email communications, but also saves the costs of visiting the manufacturer’s outlet.

Information Needed for PCB Assembly Instant Quotation

Take note that the processes involved in getting a quote for your PCB are streamlined through the real-time calculator on your preferred manufacturer’s website.

However, you must take note that an accurate quotation also goes beyond that. For what it is worth, the manufacturer requires you to provide as much information as possible. At RayPCB, we require our customers to provide only the important materials, as adding the irrelevant materials could increase the costs of the circuit board.

With that being said, the information required for the quotation is broadly classified into two:

- Primary materials

- Secondary materials

This information is discussed in details below.

Primary Materials

As the name signifies, these are the major materials needed for the PCB assembly. They are the basic materials or set of information that the PCB assembler would ask you to present before preparing the quotation.

The following are some of the primary materials required for the design:

- Vendor List: this is the list of the manufacturers or suppliers of the major internal parts or components needed for the Printed Circuit Board Assembly (PCBA). Submitting this information helps the PCB designer to easily reach out to the vendors to source the components.

- Bill of Materials (BOM): this is an important document that helps the PCB manufacturer to come up with a better pricing for the internal components. The BOM is typically submitted as a Microsoft Excel file.

- Gerber File: this is a dedicated document containing the different layouts of the PCB. It provides information about the different layers on the circuit board and how they are to be fabricated. The Gerber File can also be optimized into the ODB++ data interchange format. The Gerber File highlights the bare board print, including important schematics like the outer circuit dimensions, number of holes, and the circuit board’s thickness.

- The XY File: it is a dedicated document used to highlight the different points where the components are to be placed on the circuit board.

Secondary Materials

We have discussed the most important documents needed for getting the PCB assembly instant quote. However, some other materials or documents are also relevant. Most times, PCB consumers leave them out and that could influence the final costs they get.

Below are some examples of these secondary PCB materials and how they work:

- Silkscreen: you need to specify where the silkscreen is to be placed on the circuit board. Is it to be placed on one side of the board or would it be two-sided? You also need to specify the preferred color of the silkscreen.

- Stack-up Details: here, the manufacturer expects you to provide information about the number of layers to be used in the circuit board, the thickness of these layers and overall thickness of the stack-up.

- Surface Finish: what type of finish do you want the PCB manufacturer to use in the board? There are several options out there and the ones you choose depend on the overall application of the circuit board. The list of PCB surface finishes includes Hot Air Solder Leveling (HASL), Electroless Nickel Electroless Palladium Immersion Gold (ENEPIG), and Electroless Nickel Immersion Gold Plating (ENIG).

- Solder Mask: what type of solder is to be applied to the PCB? The specifications here range from the solder mask finish (such as matte or semi-gloss), solder mask sides, (such as bottom, top and bottom, and top alone), type of solder mask color (such as white, green, red, and blue), solder mask type (such as Liquid Photo-imageable (LPI)).

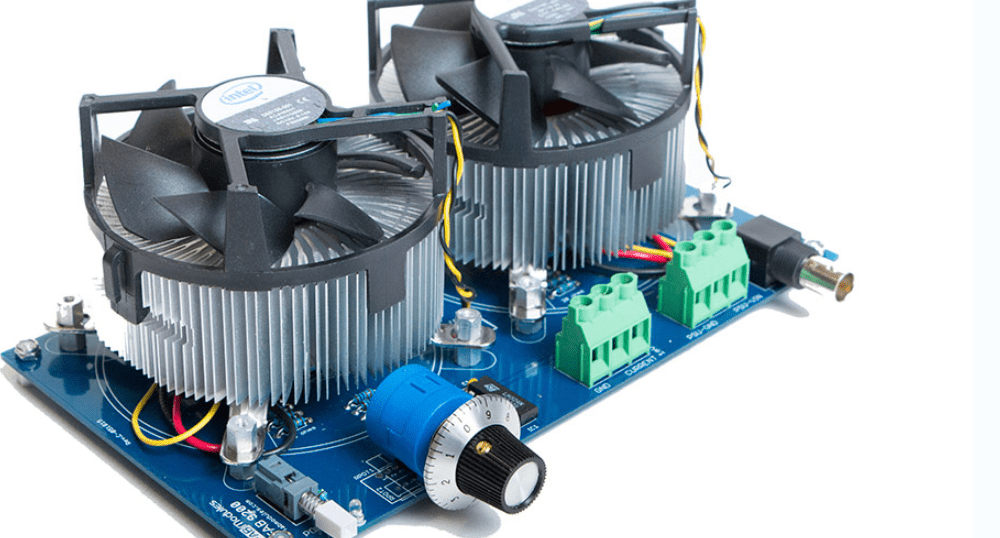

- Cut-Out Details: there are two major process technologies used when manufacturing PCBs. These are the Surface Mount Technology (SMT) and the Through-Hole Technology (THT). You have to specify the cut-out details, specifying the holes in the Printed Circuit Board (PCB). These holes are not mechanically drilled, hence, the naming as “cut-out.” Providing this information helps the manufacturer to note the dimensions of these holes, as well as the positions they are located in the PCB.

The Major Types of PCB Assembly Instant Quotes

There are three (3) major types of PCB assembly instant quotes. The choice of any of them depends on the type of Printed Circuit Board (PCB) you want to design.

Below are the major PCB assembly types:

- Mass Production PCB Assembly: a majority of PCB assembly instant quotes are for the circuit board prototypes. However, you can get quotations for mass productions, which have to do with higher volumes of the boards.

- Prototype PCB Assembly: as mentioned, this is the most popular type of PCB assembly. The quotations requested here are for the overall costs of making the prototypes or first set of designs to be tested ahead of the final production. It is common for the prototype PCB assembly quotation to be for fewer or limited quantities of the circuit board.

- Turnkey PCB Assembly: in this type of PCB assembly instant quote, the quotation is for the overall cost of handing the circuit board design to the manufacturer. It is usually for higher quantities of the board and costs more money.

The Step-by-Step Process to Getting PCB Assembly Instant Quote

You are now ready to get the quotation for your PCB assembly. How do you go about it? The following are the steps to take:

1. Choose the Best PCB Assembling Company

This should be your first step. If you picked the best company, you can be sure of not just getting real-time quotation, but also the designs at the most affordable costs. RayPCB is a reliable PCB assembler. You can rely on our services to be fast-paced, optimized for your target applications and we work with your budget.

2. Sign up with the Manufacturer

Visit our website at https://www.raypcb.com/ to sign up for an account? Why should you create an account? It helps us to have your quotations in one place.

However, if you don’t intend to sign up, we can always use the email address you provided to reach you and possibly create a temporal account to keep your information together.

3. Choose and Prepare the Relevant Files/Documents

From our order page, you can see the list of documents we expect you to provide. These documents need to be submitted in the corresponding formats.

Below are some examples of the documents you need to provide to get the PCB assembly instant quote:

- Fabrication Print: also called the board print, this document contains the circuit board drawing, such as the hole sizes, board outline and drill pattern.

- Readme.txt: this is a file detailing information about the layer stack-up and the Printed Circuit Board (PCB).

- Excellon Drill File: this is a document containing information about the board number formats, units, and coordinates. The Excellon Drill File is commonly submitted as an ASCII file format.

- Bill of Material (BOM): the BOM contains information regarding the components or parts needed for the Printed Circuit Board (PCB) design.

4. Board Specifications

We will also ask you to provide information about the type of circuit board design you want. You can choose from any of the options on our site or make a custom input.

The following makes up some of the circuit board specifications we will ask of you:

- Layers: how many layers do you want for the board? You can choose anywhere from 1 and 20 layers.

- Type of PCB: you should also select the type of Printed Circuit Board (PCB) you would like us to work on for you. The options include, but are not limited to Rogers PCB, Aluminum PCB, Rigid PCB, Flexible PCB and FR4 PCB.

- Color: we will ask you to select the type of color needed for the PCB. The color options cover the Soldermask, Silkscreen Legend Color, and the Matt Color.

- Surface Finish: we have lots of surface finish types to choose from. The options include but are not limited to Immersion Tin, Hot Air Solder Leveling (HASL), Organic Solderability Preservatives (OSP), Lead Free HASL, and Electroless Nickel Immersion Gold (ENIG).

5. Upload the PCB Assembly Files

Now that you have selected the most important properties of the circuit board, it is time to submit it. There are several options to submit it but it is better to submit the BOM file as a CSV file. You can also choose from any of the supported file formats on our site to upload the files.

6. Receive Your Quotations and Pay

Since this is a PCB assembly instant quote, you can be sure of getting the quotation in good time. Just stick around on our site for a few minutes while we run the calculation.

In a few minutes, you will get the quote. Proceed to confirm the details, before using any of the payment methods to place your order.

Final Words

RayPCB can process your PCB assembly instant quote in a few minutes. We also have an online representative to attend to your concerns. If you want to process the order faster, consider allowing us to source the components and handle the shipping.

Comments are closed