Different kinds of Printed Circuit Boards (PCBs) have been manufactured for use in different industries. The Metal Core Printed Circuit Board, otherwise called the MCPCB is one of such PCBs. In this article, we talk about what this type of PCB does, and how to choose the best manufacturers for it.

What is Metal Core PCB?

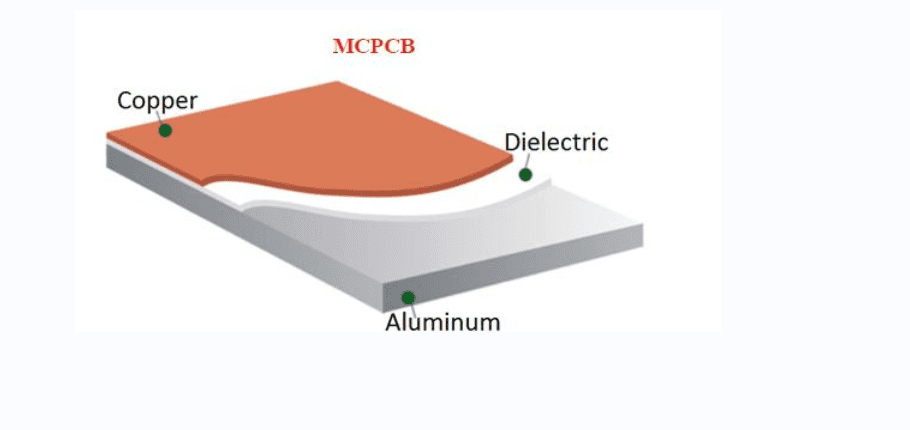

It is a type of Printed Circuit Board (PCB) with a metal as the base material. According to RayPCB, the MCPCB is also a “PCB having its base material as metal for the board’s portion that spreads heat.”

In light of the continued demands for circuit boards with higher heat dissipation capabilities, it is impressive to see that the MCPCB can offer more of that service. The heat dissipation capabilities include but are not limited to:

- Redirecting excessive thermal energy (heat) from the crucial parts of the circuit board.

- Helping in moving heat out of the areas that might be negatively impacted, due to excessive heat on the circuit board.

Using MCPCB in the LED Industry

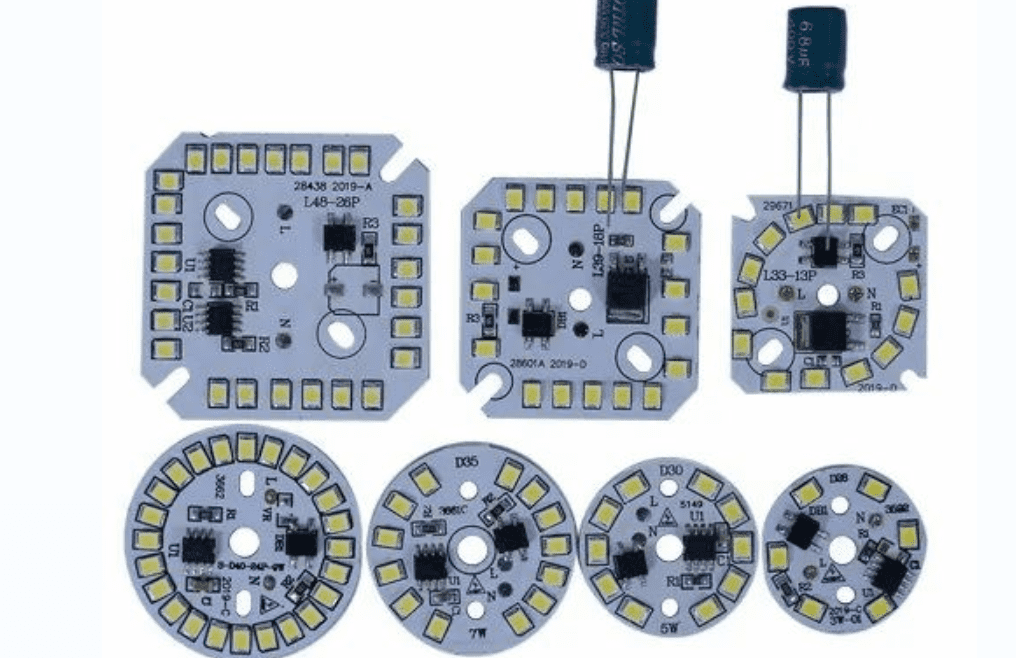

There has been an astronomical increase in the numbers of Light Emitting Diode (LED) products. LEDs are greatly needed in a variety of lighting solutions, including electronics and street lights.

However, one downside to these LEDs is the higher heat dissipation capabilities. Since these LEDs can emit or dissipate more heat than necessary, it became imperative to find a way to remove a great deal of that heat.

Metal Core Printed Circuit Boards (MCPCBs) came to the rescue, as they serve as “conductive cooling elements” to facilitate the removal of excessive heat.

Simplified Cooling Process

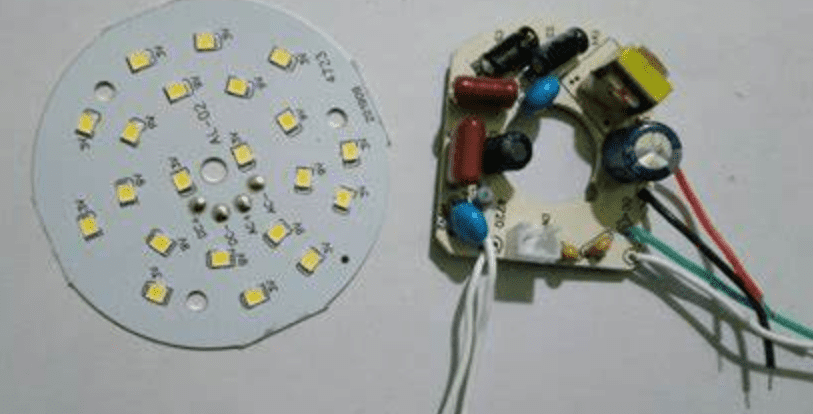

Using the MCPCB in LED products helps to streamline the cooling process as a way of reducing the excessive heat dissipation coming from these products. Below are some of the creative ways to make that happen:

- The integration of MCPCBs in the LED products helps to reduce the number of Light Emitting Diodes (LEDs) required to provide light or illumination.

- The MCPCB can also streamline the heat dissipation process by using the aluminum PCB base as a “connecting point” to combine with the dielectric layer. The combination allows the MCPCB to connect both the Integrated Circuit (IC) and the heatsink for excellent heat passage in the LED products.

1. RayPCB

RayPCB is one of the MCPCB suppliers you should talk to if you want to get value for your money. Aside from being in the industry for many years and having several clients from different parts of the world, RayPCB is also reputed for the quality of the MCPCB designs.

The company’s Metal Core Printed Circuit Board (MCPCB) capabilities include but are not limited to:

- Making a variety of holes, ranging from 4mil to 16mil.

- RayPCB uses different kinds of materials for the MCPCB designs. These materials range from iron base, aluminum base and copper-based materials.

- As a way of ensuring evened-out surface finish, the company offers an extensive list of surface treatment options. These options range from the Immersion Silver, HASL, Lead-Free HASL and ENG Gold

- RayPCB also offers a wide range of solder mask color options. These colors include blue, white, green, purple, red, black and yellow.

- On the flipside, the company only offers 4 layers for the Metal Core PCB.

2. Best Technology

Are you looking for a MCPCB supplier that understands the technicalities involved in making this kind of circuit board? Look no further than Best Technology. This supplier is committed to offering you a great deal of MCPCB service.

From the website, you can reach out to the customer representative and within 12 hours, you should get answers to your queries.

In terms of the MCPCB capabilities, the company has the following outstanding advantages over the competitors:

Multiple Layers

Best Technology can process your MCPCB orders up to 10 layers.

Different Surface Finishes

From the basic surface finish of HASL to the advanced variant of Selected Gold Plating, this supplier offers them all. The list of supported MCPCB surface finishes/treatment options also include:

- ENIG

- OSP

- Hard Gold Finger

- Flash Gold

- Gold Finger

- Silver Immersion

- Gold Plating (up to 50mil)

- ENIPIG

- Tin Immersion

- HASL (LF)

- ENEPIG

Lead Time

Best Technology offers lead time, based on the quantity or requirements for the MCPCB. For example, the company makes an MCPCB prototype of 1 layer between a week and a week and a half. However, you can request an expedited service, which could take 48 hours.

The 6-layer MCPCB can take up to 5 weeks.

Nonetheless, you can always request an expedited service for the number of MCPCB layers you wish to design. It may cost you a little extra.

MCPCB for Different Markets

While Metal Core PCBs have found the way into the LED market, it can also be used in other markets. Best Technology offers the MCPCB design service for the following markets:

- LED Lighting

- Sinkpad PCB for light-curing equipment

- Household lighting

3. Buljin Elmec Pvt. Limited

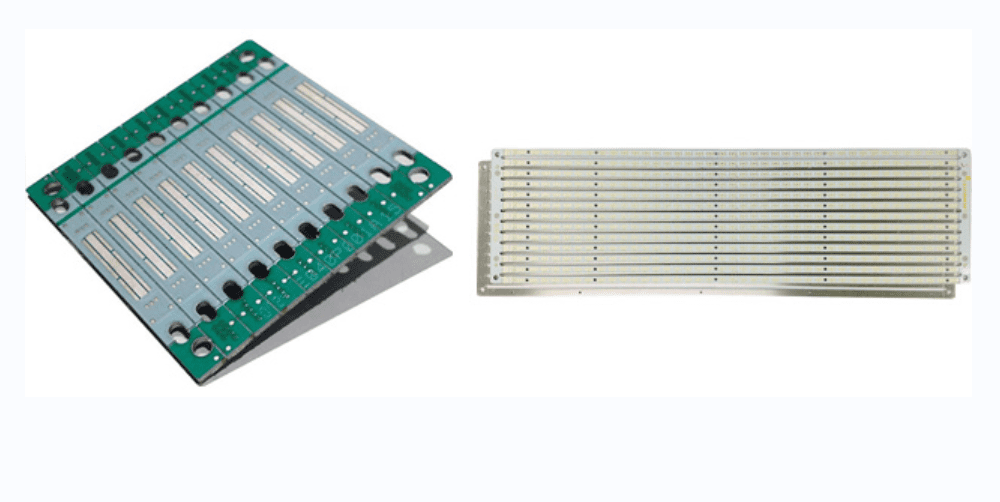

Buljin is an Indian MCPCB supplier. The company offers an extensive service ranging from the designing, manufacturing, tool punching and V-grooving to supply in panels. The company also specializes in reflow oven for soldering SMD LEDs.

The MCPCB Solutions

Buljin offers different kinds of Metal Core PCB services. The core service offered here is the production of MCPCBs for use with the LED light applications. The company also supplies the LED light accessories to buyers.

The LED Focus

Considering the overall adoption of MCPCBs in the Light Emitting Diode (LED) market, it is not surprising to see that Buljin focused on that. The company’s commitment extends to manufacturing high-quality Metal Core PCBs (MCPCBs) for use with the high-power LED lights applications.

In addition to that, the company also optimizes the MCPCBs to fit into a variety of LED lighting solutions, including:

- Cove lights

- Down lights

- Solar lights

- Home lights

- Street lights

Excellent Lead Time

Lead time has to do with the time or duration it would take for an MCPCB to be prototyped and the final design readied. Buljin offers one of the shortest lead times, starting from a week for a 100 Minimum Order Quantity (MOQ) of the circuit boards.

MCPCBs in Different Materials

Buljin also manufactures the Metal Core PCBs using different materials. The major material used is the aluminum base copper clad.

4. MADPCB

Here is another MCPCB supplier specializing in offering different kinds of Metal Core PCB services, ranging from the single to the double-sided boards.

Below are some of the reasons why you want to work with this reliable MCPCB manufacturer:

Custom Board Design

You want an MCPCB supplier that takes the specifications you have for the board and makes something unique out it. MADPCB is the manufacturer you should contact. As experts in this field, the company helps you finetune the type of Metal Core board you want.

All you are expected to do is to provide in-depth information regarding the type of board, the technology to use and the schematics.

MCPCB Prototyping and Production

Sometimes, it is better to make a prototype or “earlier version” of a Printed Circuit Board (PCB) before making the final design. That should help you find out potential errors and address the same.

You can be sure that MADPCB will be ready to take your design specifications into consideration when making this prototype.

Once the prototype is read, you can go through it and even send it for use in a mini market or application use to ascertain the working conditions. Thereafter, MADPCB will be willing to make the final design of the circuit board, based on the final conclusions on the design.

5. JHYPCB

If you are looking for the best MCPCB suppliers to work with, why don’t you go for the companies that have distinguished their services from the rest? If that be the case, JHYPCB has to be one of the manufacturers to have on the list.

The following points express the reason why we arrived at that conclusion:

In-House MCPCB Design

Printed Circuit Boards (PCBs) make the process of reoptimizing consumer electronics for the best performance easier. However, the process of designing these circuit boards can take a lot of time and if you are using multiple suppliers, it takes even more time.

That is why it is better to work with MCPCB suppliers that have an in-house designing process, thus, reducing the time spent going back and forth with communicating the different manufacturers.

JHYPCB’s in-house team places a premium on excellent MCPCB design, while offering the customers value for money. At the core of the services is the company’s commitment to take responsibility of the process, including the design challenges that might come up in the process.

JHYPCB Offers Varied MCPCB Services

From prototyping to circuit board assembly, the company offers these variations to meet the customers’ expectations.

The outstanding service is the MCPCB turnkey service, where everything relating to the circuit board’s optimization is handled under one roof.

Designs of Low and High-Volume MCPCBs

Whether you are looking to make prototypes of 10 MCPCBs or placing larger volume orders, you can be sure of getting them done in good time. JHYPCB is capable of fulfilling your small and large Metal Core PCB orders “without the restriction of the minimum pieces.”

Compliance with Industry Standards

If there is any important consideration in PCB design, it has to be the manufacturer’s compliance with the existing industry standards.

JHYPCB meets this requirement, as it follows the industry standards of manufacturing MCPCBs, while continually optimizing and using the latest technology to make the design process seamless.

The list of industry standards and quality management systems the supplier has in place includes:

- UL

- RoHS

- IOS

Advantages of MCPCB to Standard PCB

If you are to choose between the traditional circuit board and the MCPCB for LED products, the choice would most likely be the latter. Metal Core Printed Circuit Boards (MCPCBs) have become the perfect choice for LED product manufacturers, who are looking to improve the performance of the products.

The following underscore some of the reasons why you need to get the Metal Core PCB for your next LED product release:

Excellent Heat Dissipation

One of the advantages of this type of PCB is that it offers a higher heat dissipation capability. This is because of the 9 times heat dissipation capability, when compared to the FR4 PCB.

Improved Performance

One of the major improved features that the MCPCB offers is the ability to offer a lowered thermal resistance, via the integration of a dielectric polymer layer with a high thermal conductivity.

It also improves the circuit board’s performance via the cooling of the “heat-generating components.” That way, these components wouldn’t be overly exposed to heat, which in turn, improves their lifespan.

Choosing MCPCB Suppliers: Key Points to Observe

Just setting out to pick a MCPCB supplier is not the best way to go about it. You have to consider some important factors, ranging from the supplier or manufacturer’s experience, the customer experience and the extensive list of MCPCB services it offers.

Below are some of the key points you want to look for when choosing MCPCB suppliers:

Check the Supported MCPCB Materials

What type of materials do the manufacturer use? The core MCPCB materials are Chip on Board (COB), Aluminum PCB and Iron-based PCB.

Each of those work perfectly, but depending on the type of application, you want the manufacturer to offer them all so you get to choose from the options.

Design Guidelines

There are three (3) major guidelines to designing Metal Core PCBs. These are:

- Single-sided MCPCBs

- Double-sided or 2-layered MCPCBs and;

- NPTH Drills

Find out the Level of Experience

Experience includes the number of Metal Core PCBs the supplier has manufactured and the customers’ satisfaction. You should be able to confirm that from the supplier’s “Testimonial” page on the website.

You can also use independent platforms like Trustpilot to verify the MCPCB supplier’s reliability.

Conclusion

To wrap it up, you can rely on RayPCB to deliver the best Metal Core PCB optimization for your brand. Reach out to us today or request an instant quotation for our MCPCB service.

Comments are closed