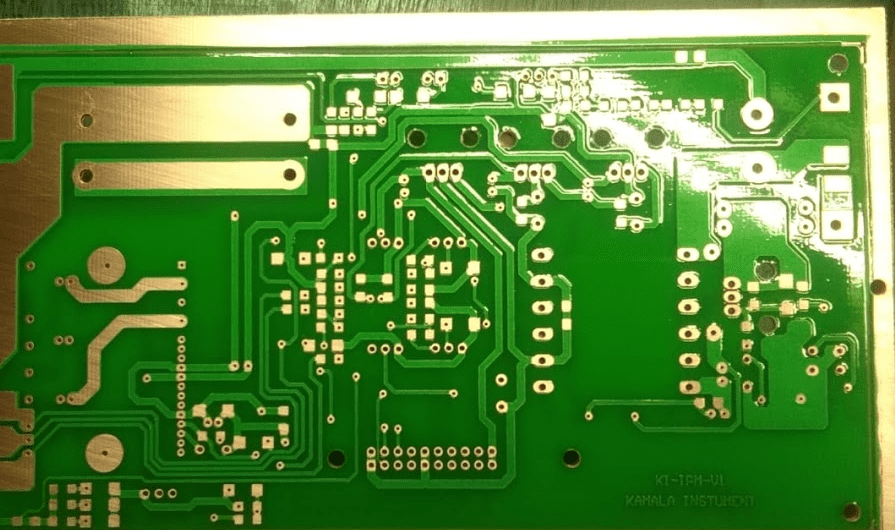

All the circuitry and electronic parts of a single-sided PCB are present on the same part of the board.

One-sided printed circuit boards (PCBs) are the most basic type. They feature a single sheet of conducting material. And they are most useful in low-density layouts. Also, the holes in such boards are typically not tinned through.

The circuitry is on one half, and the component piece design is on the other. Single-sided PCB is single-layer PCB. This PCB gets its name from the fact that it only has a single conducting layer. Since the schematic has limitations. There is only a single-sided conductor, and also, no crossover is allowed; each wire has its own route. It is more common to find it in older PCBs.

Screen Printing or Network Printing is typically useful for single PCB diagrams.

That is, printing a resist layer onto the copper, etching, and printing a solder mask. And then punching out the soldered hole and contour to complete the item. You can also use photoresists to pattern circuits in a wide variety of devices. But only for a very small percentage of these items.

Single Printed Circuit Board Material

Typically, copper-clad and foil-clad laminations are useful for constructing single-sided PCBs. When deciding on plates, it’s important to think about their electrical efficiency. Besides this, practicality, processing needs, and economic data are considerable. Copper-clad laminations, such as phenolic paper laminations, copper laminations, and epoxy paper laminations, are frequently useful. Epoxy glass fabric, epoxy foil, epoxy phenolic glass fabric lamination, metal-clad PTFE glass fabric laminate, and copper-clad phenolic glass fabric laminate are all useful in the construction of multilayer circuit boards.

Low-Cost Single PCB Manufacturer

Because of advancements in single-sided PCB fabrication equipment and technology, the cost of a single PCB has decreased in a predictable and timely manner. In most cases, vendors won’t offer price quotes over the phone. Those looking for prices on a single PCB can do so by contacting Raypcb Devices.

Single Pcb Manufacturer

RayPCB is a cutting-edge company that focuses on single-sided printed circuit board manufacturing and development. Single-sided aluminum printed circuit boards, single-sided PCBs, and other types of FR-4 circuitry get manufactured using technology online that is found in leading-edge international products. These product specs are applicable to all electronic devices, including watches, general-purpose PCs, calculators, big laptops, electronic communications systems, and even military equipment. Finally, if there are electrical devices like ICs, PCBs get employed for electrical connections.

The Time Required to Create a Single Pcb

When designing a single-sided PCB, what should you prioritize?

· Manufacturing Time

Sample production takes 3 to 5 days, while full-scale production takes 5-7 days.

· A Question of Quality

How big it needs to be, how thick it needs to be, how well made it has to be, whether it needs to get billed if it needs to get collected through express delivery, and if there are any other particular

· Predictions

Are plans for mass production inevitable? Does this cooperation have a future? Each person should figure things out independently.

In what ways can we shorten the prolonged single-sided PCB delivery time?

- Add to your supply of boards.

- Create a schedule for the entire day’s worth of work

- The date of delivery is subject to customer negotiation.

Different Kinds of Single PCB

Five distinct kinds of single-layered PCBs are now available in the job market.

Single-layered Rigid Printed Circuit Boards

It’s a single-layer printed circuit board. They can only get constructed from rigid materials like fiberglass. Since circuit boards are quite stiff, they are safe from getting bent or broken. They are now used in a variety of electronic devices, from power supplies to calculators and beyond.

Flex PCBs with a single layer

A single-layered printed circuit board made of flexible plastic instead of an inflexible one is an example of this type of board. They also incorporate plastic parts. The price of single-layered flexible PCBs is higher than that of their stiff counterparts, although these boards have advantages in some situations.

High-frequency single-layered printed circuit boards

These PCBs, which are a special instance of single-layered boards, are commonly used in the GHz frequency range. PPO or Teflon has usage in making electronic boards. Water absorption, dielectric loss, thermal expansion, and other issues must get consideration when purchasing single-layered PCBs of high frequency.

Circuit boards with a single layer of stiff flex technology

Such a PCB has a single layer and is made of a plastic and glass fiber composite. Single-layer elements include common synthetics like fiberglass and plastic. Multi-layered boards have many advantages over single-layered flexible and rigid PCBs, such as reduced size and weight.

Components Circuit Boards with an Aluminum Backing

It’s a printed circuit board made with an aluminum sheet and a single layer of insulation. They share a design with copper-backed boards but utilize an aluminum substrate instead.

Double Sided vs. Single Sided

Single and double-sided PCBs differ in several significant ways. Some examples of these distinctions are:

· Power

Due to their low power requirements, single-sided boards are commonly implemented in low-powered electronic devices. To improve the substrate’s conductivity, double-sided versions get employed. A double-sided board has through holes on both sides. They also stay attached since they’re linked through holes.

· Substrates

A single layer is used for single-sided PCBs. In contrast to multi-layered PCBs, double-sided PCBs only contains two layers. Tri-layer boards comprise three major layers and are single-sided. Soldering mask, silkscreen, and conducting material are the three layers that make up a PCB. On both faces of a double-sided board is a conducting route that allows electricity to flow. Copper, silkscreen, and soldering mask make up both of these faces.

· Price

When compared to double-sided PCBs, single-sided PCBs have a lower production cost. The simplicity of their design and the low cost of production is largely responsible for this. The circuitry on double-sided PCBs is significantly more intricate. It’s because there’s so much more room to spread out in. Due to the increased flexibility afforded by the board’s layout, it gets utilized for more complex circuits and more demanding uses. In addition, the circuit board can be made smaller because both sides become usable. Due to the increased component density per unit area, double-sided PCBs can get manufactured for less money than single-sided PCBs.

· Usage

Single-sided PCBs are used in consumer electronics that get sold at a low price. However, double-sided boards are typically employed in higher-powered and more robustly protected devices. They are also put to work in places with complex electronics and software.

In what ways should a Single-Sided PCB be maintained?

Engineers specializing in circuit boards have their own approaches to routine upkeep. However, the actions involved in maintenance can get boiled down to the following six. Repairing a faulty board requires an understanding of the failure circumstance and the setting of the failed assessment within a narrower range to make for easier maintenance. Therefore, it is crucial to first identify the cause of the electronic circuit failure before beginning any repairs.

· Observation of Board

Observing a board is a good way to get a head start on your investigation. The goal is to learn where the board’s various control components are located, what functions are implemented, and what input/output interfaces are available.

· Circuit Testing

After you’ve finished analyzing your fault observations, it’s time to move on to the first round of your circuit test: visual inspections. Even if the circuit test fails to pinpoint the source of the problem on the board, skilled technicians will be able to manually run the test, rule out many potential causes, and clear the way for further repairs.

· Inspection of Components

During a component examination, the components are typically unsoldered from the PCBA board with the help of a soldering gun and then examined with specialized equipment. Because of the risk to the circuit board’s outside, maintenance staff will typically avoid disassembling parts in this way.

· Faults maintenance

Repairing faulty components, lines, and transformers is all part of the fault maintenance process that begins with the inspection and testing of individual parts.

· Computerized Testing

The serviced board must pass another checkup. No flaws were identifiable. Therefore, it was time to put it through its paces on the computer.

Characteristics and Applications of Single Pcb Manufacturer

The following is an overview of the many special benefits of the single-sided board, which is leading to its increasing popularity.

· High Density

Increasing IC integration and better mounting techniques have led to the development of high-density printed circuits over the course of several decades.

· High Reliability

The PCB has passed multiple tests, aging tests, and inspections, ensuring its high dependability and long service life (usually 20 years).

· Designability

The printed circuit may be designed quickly and efficiently thanks to design standards, meeting the many different performance criteria (mechanical, chemical, physical, and electrical) of a single panel.

· Producibility

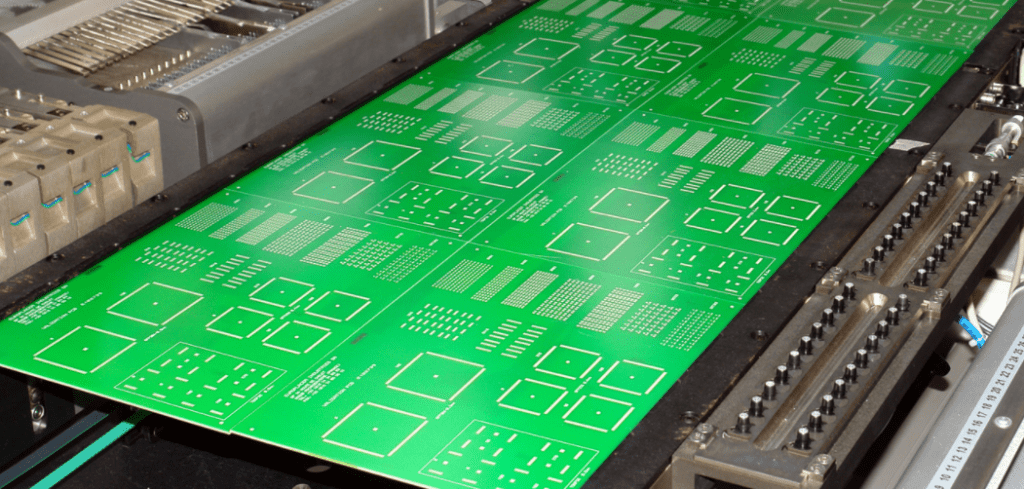

The ability to mass produce something means that it can be managed in a way that guarantees a constant level of quality from batch to batch.

· Testability

The single PCB’s service life and eligibility may get detected and evaluated. Thanks to established test techniques, standards, a wide range of test instruments, and equipment.

· Fabrication

The circuit board makes it possible to mass-produce items in an automated, standardized fashion on a big scale. Additionally, smaller pieces and systems can get constructed from circuit boards and other element assembly parts to create larger parts and the final machine.

· Maintainability

Printed Circuit Boards and other component manufacturing parts are mass-produced in standard scale and design. In the event of a system failure, you may easily swap out faulty parts, allowing you to get everything back up and running in no time. More examples include making the system smaller and lighter and sending signals at a higher rate.

Single-PCB Characteristics

Because all the components get grouped together on a single side, and the cables get grouped together on the other, a single-sided PCB is the simplest form of the printed circuit board. A single-sided PCB has wires that only show up on one side. Single-sided boards were used in the past but are rarely used today due to their restrictive design. There is only a single face, and the cabling cannot crossover and must travel around a different pathway. They are still in use in some historical contexts.

Network printing is typically used for single-PCB wiring schematics. After etching, a soldering mask is used to print the logo onto the metal surface, which acts as a resist. Finally, a guide hole and the desired form get punched into the component. In addition, photoresist-producing patterns are used in the production of several low-volume, diverse items.

Advice for designing a single-layer printed circuit board

If you follow these steps, creating a single-layered PCB won’t be difficult at all.

Different Vias

In short, vias are what make it possible to make connections between the boards’ many layers. Due to variations in panel thickness, different types of boards may necessitate the usage of several vias. There are several options available to you: micro, buried, or through the hole.

Trace thickness

The weight of a circuit board is directly proportional to the metal utilized in its traces. Some PCB makers may supply circuits with as many as 6 ounces of metal. However, most PCB developers only use a few ounces.

NOTE: Using the wrong trace thickness can cause problems with soldering and lamination.

One-sided printed circuit board (PCB) design

In order to find out the most basic elements of your PCB, it is necessary to construct a basic stack guide. The amount of money and time spent on fabrication and necessary components is directly proportional to the PCB’s complexity.

Regulatory Constraints on Building Projects

Always explain your requirements before the production of PCB to ensure that it is as per your standards. Things to consider are where to put things, how to divide up the layers, how long the flight would be, and how long it would take to design.

Superior signal quality

Note the signal’s rise and fall times, as well as any impedances, lengths of track, or drive intensities. Put your plan through its paces both before and after you finish the layout to evaluate if your work paid off.

Conclusion

We can provide the appropriate PCB solution for your project, whether it calls for a single-layered flexible PCB or a single-layered rigid PCB.

Whatever the case may be, you can rest assured that you will only receive the highest quality materials from the IBE quality assurance department. We can help you with complex structures, electrical manufacturing, and PCB manufacturing. Functional testing and PCB assembly are two other services we offer. Request a price estimate right away!

Comments are closed