Printed circuit boards or PCBs are an essential component in modern electronics, providing a compact and efficient way of connecting components together. While there are many off-the-shelf PCBs available, custom PCBs offer a way to create a bespoke solution that is tailored to the exact requirements of a project.

Creating a custom PCB may seem like a daunting task, but advances in technology have made it easier than ever before. With the right tools and knowledge, it is possible to design and manufacture a custom PCB in a matter of hours. This article will explore the process of creating a custom PCB, from designing the circuit schematic to manufacturing the finished board.

Why Print Custom Circuit Boards?

Advantages of Printing Custom Circuit Boards

Printed circuit boards (PCBs) are an essential component of electronic devices. They provide a platform for the components to be mounted and connected through conductive pathways. Custom PCBs offer several advantages over traditional PCBs, including:

-

Cost-effective: Custom PCBs can be designed and produced in small quantities, making them cost-effective for prototyping and small-scale production runs.

-

Flexibility: Custom PCBs can be designed to meet specific requirements, such as size, shape, and functionality.

-

Improved performance: Custom PCBs can be designed to optimize the performance of the electronic device by reducing noise, improving signal integrity, and minimizing power consumption.

-

Reduced assembly time: Custom PCBs can be designed to reduce the assembly time of the electronic device by integrating multiple components into a single board.

Types of Custom Circuit Boards That Can Be Printed

There are several types of custom circuit boards that can be printed, including:

-

Single-sided PCBs: These PCBs have a conductive layer on one side and are suitable for simple electronic devices.

-

Double-sided PCBs: These PCBs have a conductive layer on both sides and are suitable for more complex electronic devices.

-

Multilayer PCBs: These PCBs have multiple conductive layers and are suitable for high-density electronic devices.

-

Flexible PCBs: These PCBs are made of flexible materials and are suitable for electronic devices that require flexibility, such as wearable devices.

In conclusion, printing custom circuit boards offers several advantages over traditional PCBs and can be used to design and produce electronic devices that meet specific requirements.

How to Print Custom Circuit Boards

Designing the Circuit Board

Before printing a custom circuit board, it is important to design it first. This can be done using software such as Eagle PCB or Altium Designer. The design should include the layout of the components, the traces connecting them, and any other features such as mounting holes or test points.

Choosing the Right Materials

The materials used for printing the circuit board are crucial for its performance and durability. The most common materials used are copper-clad laminate and etching solution. The thickness of the copper layer and the type of laminate used should be chosen based on the specific requirements of the circuit design.

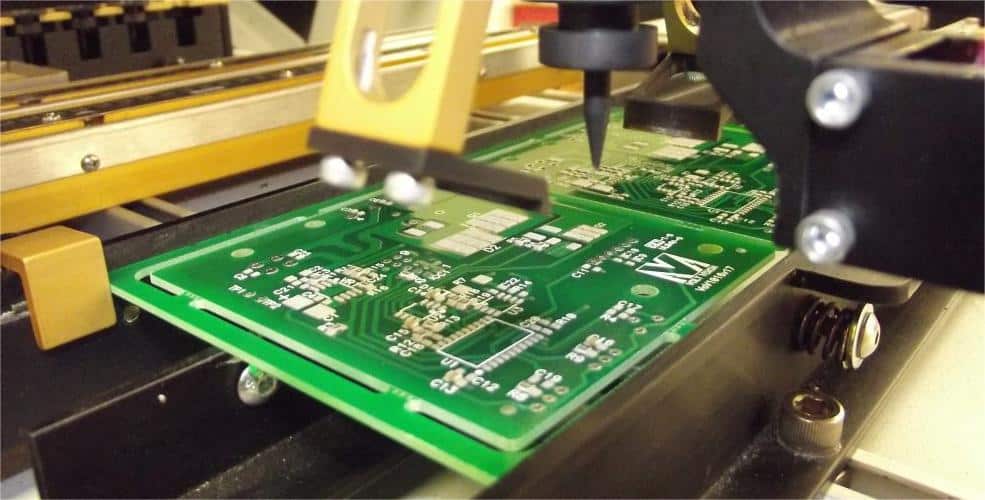

Printing the Circuit Board

Once the design and materials are chosen, the circuit board can be printed using a variety of methods. One popular method is using a laser printer and iron-on transfer paper to transfer the design onto the copper-clad laminate. After transferring the design, the board is etched using a solution to remove the excess copper and reveal the circuit traces.

Finishing the Circuit Board

After the board is etched, it should be cleaned and drilled to create holes for the components. The board can also be coated with a protective layer to prevent oxidation and improve its durability. Finally, the components can be soldered onto the board to complete the circuit.

Overall, printing custom circuit boards requires careful planning and attention to detail. By following these steps and using the right materials and tools, anyone can create their own custom circuit boards for their projects.

Tools and Equipment Required

When it comes to printing custom circuit boards, there are a few tools and equipment that you will need to get started. Here are the essential items that you will need:

Software

To design your custom circuit board, you will need software that can create a PCB layout. Some popular options include Eagle PCB, KiCAD, and Altium Designer. These software programs allow you to create a schematic of your circuit and then lay out the components on a board.

Printer

Once you have designed your custom circuit board, you will need a printer that can print the layout onto a copper-clad board. There are several options available, including inkjet and laser printers. However, it is important to note that not all printers are suitable for printing on copper-clad boards. Make sure to choose a printer that is specifically designed for this purpose.

Materials

In addition to a printer, you will need a few materials to print your custom circuit board. These include copper-clad boards, transfer paper, and toner. The copper-clad board serves as the base for your circuit, while the transfer paper is used to transfer the layout from the printer to the board. The toner is used to create the circuit traces on the board.

Chemicals

Finally, you will need a few chemicals to etch the circuit board. Etching is the process of removing the unwanted copper from the board to leave behind the circuit traces. The most common chemical used for etching is ferric chloride, which can be purchased at most electronics stores.

In summary, the tools and equipment required for printing custom circuit boards include software for designing the layout, a printer for printing the layout onto a copper-clad board, materials such as transfer paper and toner, and chemicals for etching the board. With these tools in hand, you can create your own custom circuit boards for a variety of applications.

Considerations Before Printing Custom Circuit Boards

Cost

When considering printing custom circuit boards, cost is an important factor to consider. The cost of printing custom circuit boards can vary depending on the complexity of the design, the materials used, and the quantity of boards needed. It is important to research and compare prices from different manufacturers to ensure that the cost is within your budget.

Time

Time is another important consideration when printing custom circuit boards. The time it takes to print a custom circuit board can vary depending on the manufacturer and the complexity of the design. It is important to plan ahead and factor in the time it will take to design, print, and test the circuit board. Rush orders may be available, but they can be more expensive.

Expertise

Expertise is crucial when printing custom circuit boards. It is important to have a good understanding of circuit board design and manufacturing processes. If you do not have the necessary expertise, it may be best to hire a professional to design and print the circuit board. This can help ensure that the circuit board is designed correctly and will function properly.

When considering printing custom circuit boards, it is important to keep these factors in mind. By doing so, you can ensure that the circuit board meets your needs and is within your budget.

Conclusion

In conclusion, creating custom circuit boards through print technology is a viable option for those who require a specific design or functionality. The process of creating a custom circuit board through print technology is relatively simple and straightforward. However, it requires the use of specialized software and equipment.

One of the main advantages of creating custom circuit boards through print technology is the ability to create a board that meets specific requirements. This can include size, shape, and functionality. Additionally, creating custom circuit boards through print technology can be more cost-effective than traditional methods.

It is important to note that creating custom circuit boards through print technology does have its limitations. The size and complexity of the design can impact the quality of the finished product. Additionally, the materials used in the process may not be suitable for certain applications.

Overall, creating custom circuit boards through print technology is a valuable tool for those who require a specific design or functionality. With the proper equipment and software, it is a cost-effective and efficient method for producing custom circuit boards.

Comments are closed