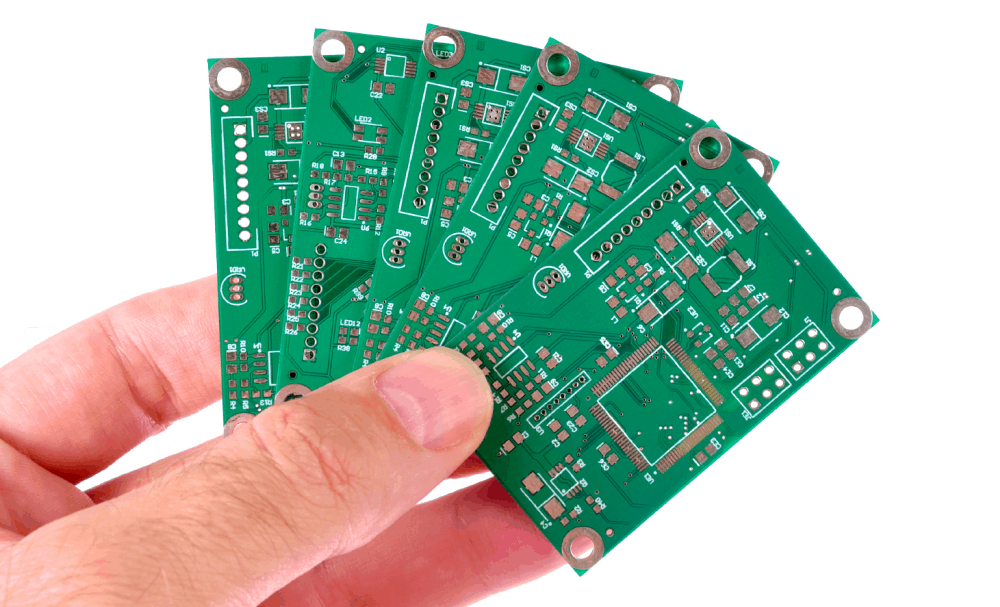

The Printed Circuit Board (PCB) has taken a special place in the heart of the manufacturing industry. Because manufacturers do not want the wire and other electrical components used in the products to be showing, they opted to use PCB.

The growing popularity of PCB is not unconnected to the organized way it connects the different points of every electrical product together.

What Is PCB?

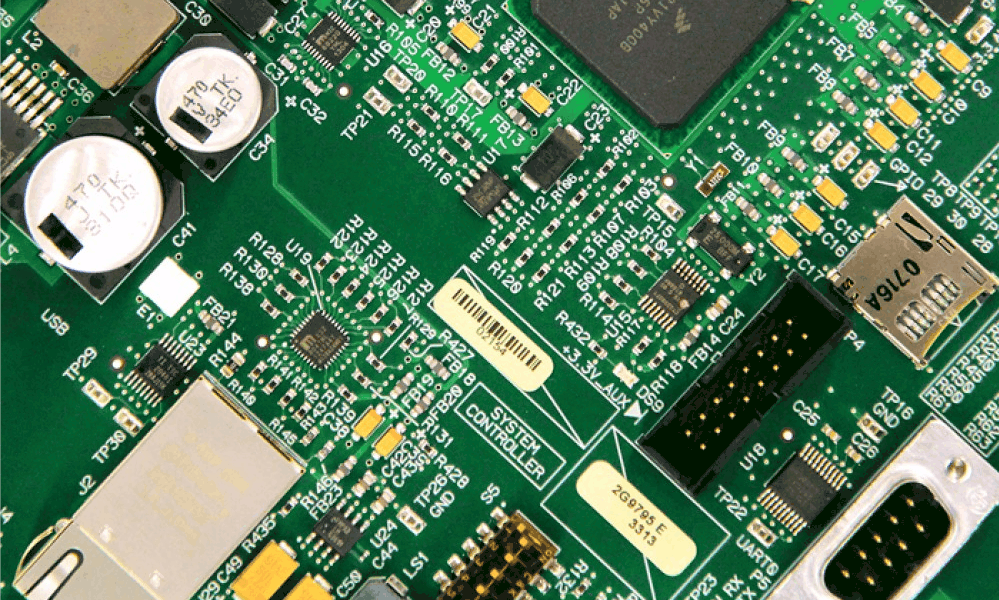

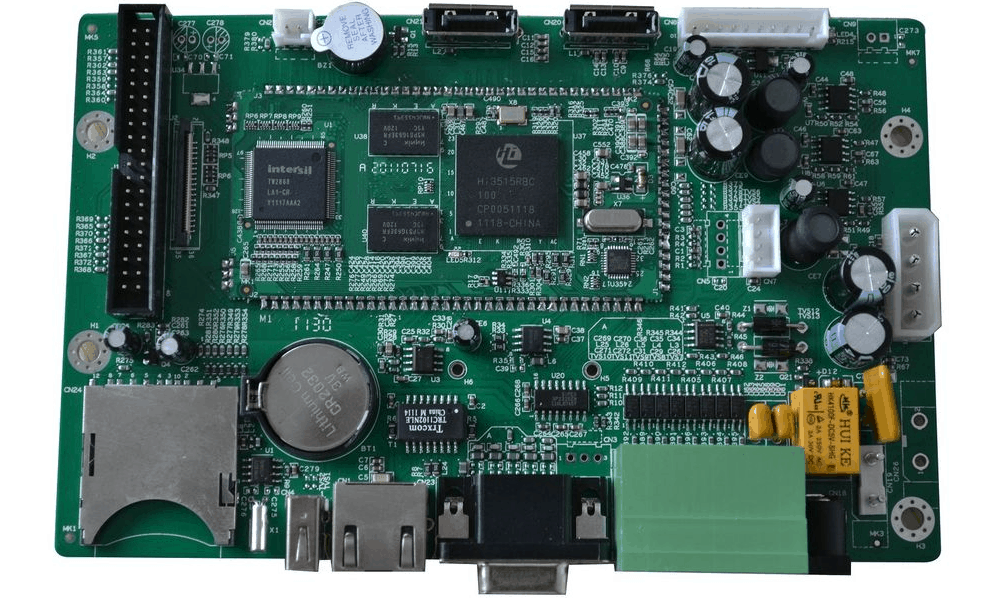

The Printed Circuit Board (PCB) is a thin board that is made from different materials, such as fiberglass and composite epoxy. After the manufacture, the board is then used alongside its pads and lines to connect the different electrical points in an electronic or electrical product.

By using the Printed Circuit Board (PCB), manufacturers can now be able to connect important electrical items to the central points on the board. Some of the items are resistors and integrated circuits.

The Turnkey PCB Assembly

The Printed Circuit Board (PCB) has different aspects to it. The Turnkey PCB Assembly is one of them.

In this article, we’ll be looking at what the Turnkey PCB Assembly means and every other thing you need to know about it.

————————————————————-

Request Turnkey PCB Assembly Quote , Pls Send PCB File to Sales@raypcb.com Now

————————————————————-

What Is the Turnkey PCB Assembly?

Before looking at the concept of the Turnkey PCB Assembly, let us look at the different terms there.

The first is “Turnkey.” Turnkey means a “product that is ready for immediate use.” Hence, it is not out of place to say that the product that is considered “Turnkey” has been thought of, conceived, and is awaiting the final production so that it can be used.

On the other hand, we have the “PCB Assembly.” It means that the company or PCB manufacturer that will be handling the ‘Turnkey Project” will be vested with the responsibility of ensuring that the expectations of the buyers are met. Ideally, the PCB manufacturer will not only be handling the production of the Turnkey PCB products. The manufacturer will also be making relevant suggestions that will help in making the project a success.

That said; let us now consider what the Turnkey PCB Assembly means. In this instance, the company that will be manufacturing the Turnkey PCB projects will be in charge of performing the turnkey delivery of the Printed Circuit Board (PCB) assemblies.

Second, the PCB manufacturer will also take full responsibility of the entire production process. This means that you don’t have to worry about outsourcing or giving out different parts of the Turnkey PCB project to different companies to handle. Instead, one company will handle everything.

Third, the concept of the Turnkey PCB Assembly empowers you (the project owner and buyer) to upload the designs of the files you expected to be manufactured. This helps the Turnkey PCB manufacturer to have an idea of what you are expecting. After you must have uploaded the files and designs, you will get a quote for the project. This is usually via the website of the Turnkey PCB manufacturer.

The Role of the Buyer

Both the buyer and the manufacturer of the Turnkey PCB products have some roles to play to ensure the success of the project.

On the part of the buyer, the primary responsibility is to make researches and come up with the designs of the files that is expected at the end of the manufacturing stage.

Also, after getting the designs of the files, the buyer is to visit the website of the Turnkey PCB manufacturer to upload the designs and get quotes for the same.

It is important to mention that the buyer has some additional things to take note of. These are:

- The buyer will have to supply the designs of the files in the form of PCB Gerber Files. Aside from that, the buyer can decide to upload the files in the form of a digital format or an artwork variation for easy comprehension by the manufacturer.

- The buyer will supply the complete Annotated BOM that has component designators. The designators must match the component placement files

- Indication of the component placement files with the X and Y locations

- Solder Silk Screens, Drill Drawings, and Solder Masks will also be supplied.

The Role of the Turnkey PCB Manufacturer

The Turnkey PCB Assembly manufacturer has more roles to play in ensuring the success of the project. Once the buyer has uploaded the designs of the files on the manufacturer’s website, gotten the quote, and given the go-ahead for the project, the manufacturer’s job instantly starts.

Here are some of the expectations or roles expected of the Turnkey PCB Assembly manufacturer:

- Procurement

Based on the specifications of the Turnkey PCB Assembly project (as specified by the buyer), the manufacturer will have to source and procure the needed parts and components.

Usually, some of the parts and components may not be available at the manufacturer’s because the Turnkey PCB Assembly is often an on-demand project. So, the manufacturer will have to order for the parts and components when it receives the orders for such projects.

- Cloud Development

With the innovations in technology, the Turnkey PCB Assembly manufacturer doesn’t necessarily need to stick to the traditional format of the Turnkey PCB Assembly production.

Instead, Internet Cloud-Based Software can be used to facilitate the generation and development of the Printed Circuit Boards (PCBs).

That makes it less tedious for the company. It also makes the job fast.

The Turnkey PCB Assembly manufacturer will also handle the following:

- Manual routing or SMAT Automation Setup

- Fabrication of the blank boards

————————————————————-

Request Turnkey PCB Assembly Quote , Pls Send PCB File to Sales@raypcb.com Now

————————————————————-

Benefits of Turnkey PCB Assembly

Many benefits come with using Turnkey PCB Assembly. If you are wondering about the advantages or the things you will stand to benefit as a buyer, we got you covered.

We have discussed below, some of the benefits of using Turnkey PCB Assembly.

- Instant Quotes

The speed of the PCB projects weren’t part of the primary basis upon which the traditional PCB manufacturing models were founded. Now, you don’t have to worry about the longer time and delays before you will get quotes and pricing for your PCB projects.

Thanks to the innovative Turnkey PCB Assembly, you will now get instant quotes after uploading the relevant designs of the files for your PCB projects and products.

- Flexible Orders

Before and with the traditional PCB manufacturing model, buyers will have to have huge volumes of orders before they will be concerned. While this many suit the financially-buoyant buyers, it may not be the same for buyers that have fewer markets to manage.

Therefore, the Turnkey PCB Assembly is commendable because it created the room for flexible orders. It doesn’t matter if you are placing orders for low volumes or you are looking at buying more. No matter the volumes of your orders, you can be sure that they will be fulfilled after you must have uploaded your files and your project was acknowledged.

Another impressive upside to this model of PCB manufacturing is that the manufacturer is always ready to take your projects because it more of an on-demand PCB manufacturing.

In addition, the use of Internet Cloud-Based Software makes it easier for the PCB manufacturer to have real-time data of the buyers and their previous projects. So, if you are looking at getting more copies of your previous projects, they can be quickly located and worked on.

- Simplified Product Sourcing

In as much as you don’t have much role to play in the Turnkey PCB Assembly process, you can also have a hand in the success of failure of the project.

Ideally, some buyers would rather outsource different parts of the PCB project to different companies and manufacturers. Because there are multiple hands working on your projects, there may be misplacements of some parts and components from one of them.

You may not realize that on the surface level until you get ready to go through the prototype assemblage. This tends to hamper the quick completion of the project because you will have to stall the project pending when the complete components are fixed.

Therefore, using the Turnkey PCB Assembly is better. Here, the manufacturer is only one. The manufacturer also has an ongoing relationship with component suppliers.

So, you can be confident of getting the complete parts and components that will make your PCB project a success.

- One Manufacturer to Manage

To reduce the hassles of communicating with different parties and getting confused in the process, it is advised that you use the Turnkey PCB Assembly model.

In this case, you only have one PCB manufacturer to manage. Among the many benefits that come with this are:

- You wouldn’t have to manage many sellers

- Communication will be easier

- Instant manufacturing that reduces frustration and delays in PCB project completion

- Only one harmonized bill to tackle

- Beneficial if you are looking at producing prototype PCBs, which can be expensive and a slow process

- Shorter Production Times

The production time of Turnkey PCB Assembly is short. That is why you need to use, especially when you have an urgent need for PCB manufacturing.

On the part of the manufacturing, the project can be scaled up in different ways, such as:

- Limited production channels because the focus is on completing one project before starting another

- Simpler sourcing of parts and components

- Optimization of Operating Costs

If you are working on a budget, using the Turnkey PCB Assembly is ideal. Because of the Instant Quote feature that comes with it, it is now easier for you to get real-time pricing for your PCB projects.

In addition to that, you will be able to optimize your operating costs in many ways:

- You can ask the manufacturer on the quotation for higher quantities. This is important if you are looking at ordering more Turnkey PCB Assembly in the future

- Instant quotation of smaller units

- Access to Multiple PCB-Related Services

You don’t have to focus only on the Turnkey PCB Assembly. Because you are looking at reducing the number of manufacturers you are working with, it can be essential if the PCB manufacturer you are patronizing offers additional services.

Some of these manufacturers tend to provide multiple PCB-related services. Some of the services include but are not limited to:

- Provision of inventory

- Shipping of materials

- Online Portal for Streamlined Documents Management

Considering that the Turnkey PCB Assembly is carried out via an Internet Cloud-Based Software, the PCB manufacturer can also provide you with an “Online Buyer Portal.”

Through this portal, you will have better management of your Turnkey PCB Assembly projects. From the online ordering to the tracking of the projects, you will be part of the process as your PCB projects are being worked on.

Besides, you will also receive instant reports on the status of the projects. Ideally, you will get email notifications to that effect.

————————————————————-

Request Turnkey PCB Assembly Quote , Pls Send PCB File to Sales@raypcb.com Now

————————————————————-

- Prototyping

Since the PCB manufacturer will be looking at some of the potential threats to the success of the project, you will be notified of any.

During the prototyping process, the manufacture can easily identify the manufacturing defects that can negatively affect the outcome of your projects.

Therefore, it is important that you also ask your PCB manufacturer to make a prototype of the designs. It is after this that the errors can be identified, using a netlist file.

The errors, once spotted, will be fixed before the continuation of the PCB designs. That way, you are sure that everything will come out as expected; thereby saving you money and the additional time you could have spent to fix the errors if they weren’t identified.

- Real-Time Shipping

Using the Turnkey PCB Assembly also makes it complete the PCB design and ship out the same in good time.

Therefore, if you are looking for a tight turnaround time, using the Turnkey PCB Assembly could be the best decision you will ever make when it comes to PCB designing and manufacturing.

Before You Turn the Key

You can now see that using the Turnkey PCB Assembly is a good idea. Yet, you must have in mind that something may go wrong.

For instance, operational problems, such as Legal Tussles, Bankruptcy, Facility Technical Issues, and possible incompetence arising from using one PCB manufacturer can hamper the success of the project.

Those may not be a big deal but you should have them in mind. By and large, the Turnkey PCB Assembly is a great concept in the world of PCB manufacturing and should be used by PCB buyers.

Comments are closed