High-density interconnects (HDI) rigid-flex printed circuit boards are among the most flexible and long-lasting PCBs. Furthermore, due to their unique features, HDI rigid-flex PCBs are gaining popularity in many sectors. HDI rigid-flex PCBs combine flex PCBs’ flexibility with standard PCBs’ stiffness. In the following information, we will explore HDI rigid-flex PCB, several applications, their pros and cons, their manufacturing procedure, and some famous manufacturers.

What is HDI Rigid Flex PCB?

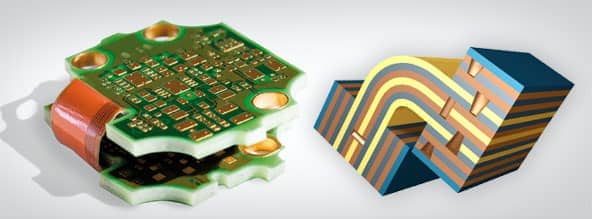

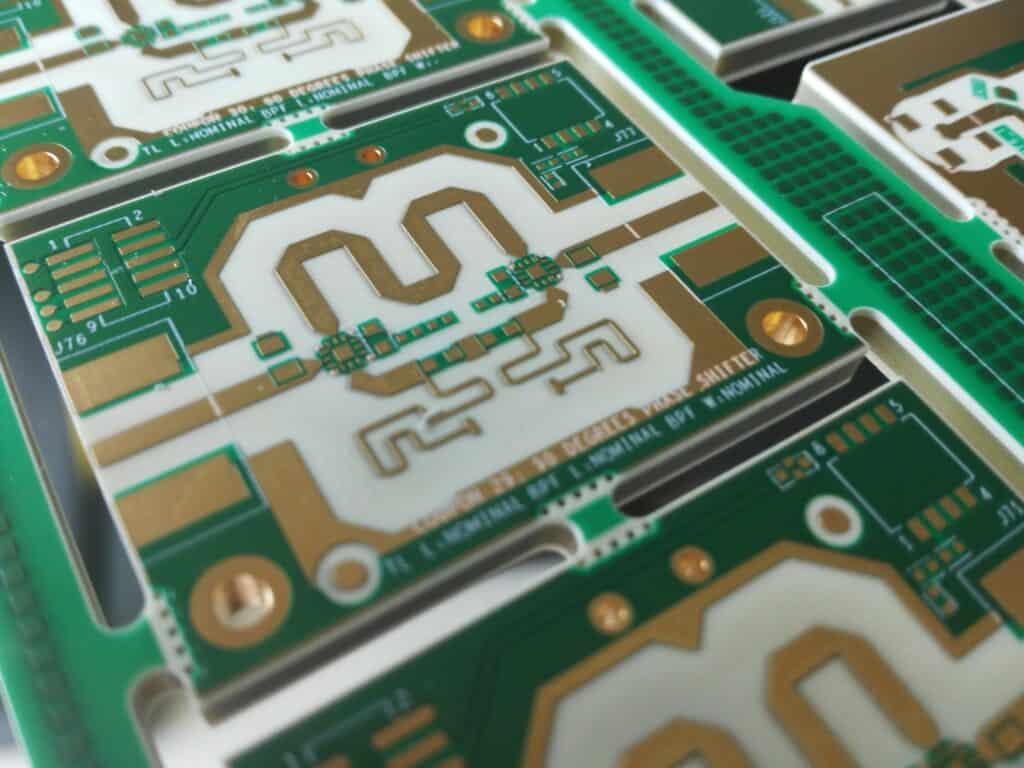

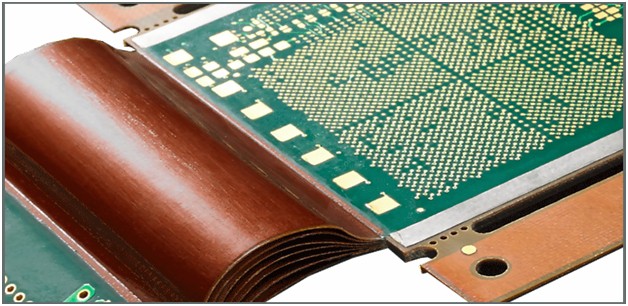

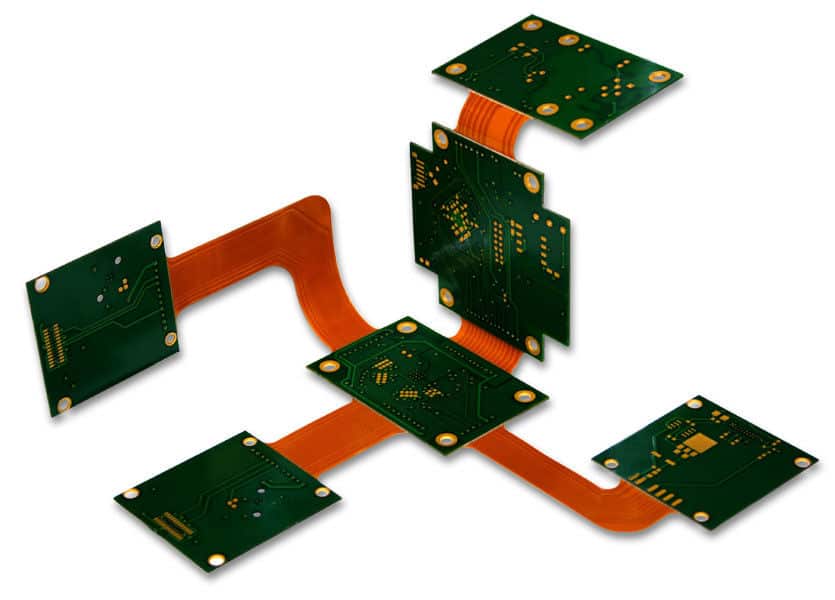

The HDI rigid-flex printed circuit board is an innovative form of the printed circuit board (PCB) that combines the characteristics of stiff and flexible PCBs. The HDI rigid-flex board consists of rigid and flexible layers bonded together. The hard layer supports the electrical components, while the flexible layer allows for the twisting or flexing the circuit board. In the manufacture of HDI rigid-flex PCBs, engineers utilize microvia technology. This technique involves using very small vias (holes) to link the various layers of the PCB. The procedure enables a very high interconnection between the different circuit pieces. Typically, HDI rigid-flex PCBs comprise FR4 and polyimide components.

Characteristics of a Good HDI Rigid Flex PCB

The following are some of the features of a good HDI rigid-flex PCB:

- The footprint of an HDI rigid-flex PCB should be modest and compact.

- A rigid-flex PCB for HDI should be very flexible and provide a large range of motion.

- The profile of an HDI rigid-flex PCB should be thin and lightweight.

- Should tolerate severe temperatures and hostile conditions.

Applications of HDI Rigid Flex PCB

In creating flexible electronics, we use HDI rigid-flex PCBs frequently because these PCBs are perfect for use in gadgets that must be flexible and resilient to some wear and strain. For instance, we have employed HDI rigid-flex PCBs in creating bendable displays, flexible solar panels, and even wearable electronics.

The creation of medical equipment is another everyday use for HDI rigid-flex PCBs. For example, these PCBs are applicable in endoscopes, catheters, and other devices that require them to be flexible and bendable. Additionally, HDI rigid-flex PCBs are commonly helpful in such medical devices like X-ray machines that must be able to endure repeated sterilizing.

Additionally, there are several military and aerospace uses for HDI rigid-flex PCBs. These PCBs are suitable for situations where weight and space are limited, such as satellites and airplanes. In addition, HDI rigid-flex PCBs are helpful in military applications where the PCB must tolerate severe heat, vibration, and shock.

Finally, there are several industrial uses for HDI rigid-flex PCBs. For example, these PCBs are applicable in robotics and conveyor belts, among other places where the PCB has to be flexible and bendable. In addition, HDI rigid-flex PCBs are suitable for industrial applications where the PCB must be resistant to harsh chemicals and temperatures.

Advantages of HDI Rigid Flex PCB

Compared to conventional printed circuit boards (PCBs), rigid-flex PCBs have several advantages, including increased flexibility, improved reliability, and better signal integrity. Here are just a few benefits rigid-flex PCBs can provide for your company:

1. Enhanced Dependability

Rigid-flex PCBs are significantly more reliable than conventional PCBs. Therefore, we can achieve excellent rigid-flex PCBs by laminating a rigid substrate to a flexible one. In addition, this design’s rigidity and flexibility help guard against breaking and cracking.

2. Improvements to Signal Integrity

Rigid-flex PCBs provide superior signal integrity to conventional PCBs. Thus, the rigid substrate minimizes signal loss, and the flexible substrate reduces crosstalk with other circuits.

3. Enhanced Versatility

Rigid-flex PCBs are significantly more flexible than conventional PCBs because they can easily bend due to the flexible substrate, making them perfect for various applications.

4. Enhanced Thermostability

They have better thermal stability than conventional PCBs, so the rigid substrate dissipates heat while the flexible substrate prevents it from building up.

5. Affordable

Rigid-flex PCBs are pretty affordable. They use easy production processes while utilizing several techniques, including photolithography, etching, and screen printing.

Disadvantages of HDI Rigid Flex PCB

Despite the many benefits of HDI rigid-flex PCBs, there are a few drawbacks to consider. Below are the main disadvantages of HDI rigid-flex PCBs:

1) Cost increase

HDI rigid-flex PCBs are extra expensive than other PCB types due to HDI rigid-flex PCB manufacturing being more active and requiring more care during the process.

- Added pounds:

They are heavier than other PCB types because the HDI rigid-flex PCB’s overall weight increases due to the lamination of the rigid and flexible substrates.

3) Increasing intricacy

They are more difficult to manufacture than other PCB types. HDI rigid-flex PCBs are consequently typically more challenging to produce than conventional PCBs.

4) Constrained options for design

There are typically fewer design options for HDI rigid-flex PCBs than for other PCB types. This is because the HDI rigid-flex PCB can only use a certain number of layers due to the laminated construction of the rigid and flexible substrates.

Manufacturing Method of HDI Rigid-Flex PCB

The manufacturing process of HDI rigid-flex PCBs is complicated and requires numerous methods. Here is a quick summary of the HDI rigid-flex PCB manufacturing process:

- Circuit design: The first phase in the HDI rigid-flex PCB fabrication process is circuit design. The circuit must satisfy the application’s particular specifications.

- PCB layout: The layout of the printed circuit board is the next phase. The structure must handle the bending and flexing during operation.

- Fabrication of the circuit: After developing and putting the circuit out, proceed to manufacture. In this phase, etch the course onto the substrate.

- Preparation of the substrate: The subsequent step is to prepare the substrate. In addition, this comprises sizing the substrate and applying the required layers.

- Assembly is the last phase in the HDI rigid-flex PCB manufacturing process. Attach components to the circuit and test the assembled board in this stage.

Top 5 HDI Rigid-Flex PCB Manufacturers Globally

The following are the most famous dealers in HDI rigid-flex PCB manufacturing:

Hillmancurtis

Hillmancurtis is the leading provider of HDI rigid-flex PCBs in the world (PCBs). Furthermore, the firm has more than 25 years of expertise in designing and producing HDI PCBs. Its comprehensive product line meets the most stringent demands for aerospace, defence, medical, and industrial.

In addition, Hillmancurtis has a robust dedication to producing the finest quality HDI PCBs in the market and has a team of engineers with expertise in designing and building these boards. The company outfits its state-of-the-art factory with up-to-date technology and equipment. In addition, its stringent quality control procedure guarantees that all HDI PCBs satisfy the highest quality requirements.

Hillmancurtis offers an extensive selection of HDI PCBs customized to match each customer’s demands. There are conventional HDI PCBs, small HDI PCBs, and micro HDI PCBs among the company’s offerings. Hillmancurtis also provides several value-added services, including assembly and testing, to give customers a comprehensive HDI solution.

Hillmancurtis is a global pioneer in HDI PCB technology, and its products are helpful in several applications, including:

Aerospace:

Aerospace applications that utilize HDI PCBs include avionics, navigation, guidance, and control systems; flight control systems; and aircraft electrical systems.

Defense:

HDI-printed circuit boards suit various military applications, including radar, missile, and electronic warfare systems.

Medical:

Medical applications that utilize HDI PCBs include medical imaging, medical equipment, and patient monitoring systems.

Industrial:

HDI-printed circuit boards suit industrial applications, including process control systems, machine control systems, and automotive electronics.

A-TECH Circuits Co. Ltd

China-based A-TECH Circuits Co. Ltd. is a prominent maker of HDI rigid-flex PCBs. The firm has manufactured high-density interconnect (HDI) rigid-flex printed circuit boards for over ten years (PCBs). A-TECH Circuits Co. Ltd has a strong commitment to supplying the industry’s finest HDI rigid-flex PCBs. Furthermore, the company’s ISO 9001 and ISO 14001-certified production facility is state-of-the-art. A-TECH Circuits Co. Ltd is devoted to supplying its clients with high-quality HDI rigid-flex PCBs.

The firm provides an extensive selection of HDI rigid-flex PCBs created to suit the most stringent criteria. HDI rigid-flex PCBs from A-TECH Circuits Co., Ltd are available in various materials, sizes, and thicknesses. HDI rigid-flex PCBs are ideal for multiple applications, including but not limited to automotive, aerospace, medical, and military.

The HDI rigid-flex PCBs of A-TECH Circuits Co. Ltd. are easy to create using cutting-edge technology and machinery. As a result, the company’s HDI rigid-flex PCBs meet the highest quality requirements. In addition, the HDI rigid-flex PCBs manufactured by A-TECH Circuits Co. Ltd. undergo rigorous testing to guarantee they satisfy the highest quality requirements.

A-TECH Circuits Co. Ltd. provides a variety of services to its clients. The firm provides design, layout, fabrication, assembly, and testing, among other benefits. The services of A-TECH Circuits Co. Ltd. are accessible to consumers worldwide.

HDI rigid-flex PCBs from A-TECH Circuits Co. Ltd is the optimal solution for various applications. The company’s HDI rigid-flex PCBs are available in a range of sizes and thicknesses to match the needs of each application.

Gold Circuits PCB

One of the most dependable suppliers of HDI Rigid Flex PCBs is Goldcircuitspcb. The firm has been operating for more than ten years, and its headquarters is in China. High-density interconnects (HDI) rigid-flex printed circuit boards are quite easy to design and produce with the team of skilled experts at Goldcircuitspcb (PCBs).

A variety of HDI Rigid-Flex PCBs, including multi-layer, buried vias, and blind vias, are available from the firm. A wide range of surface finishes is also available from Goldcircuitspcb, including HASL, lead-free HASL, Immersion Gold, Immersion Tin, and OSP.

Goldcircuitspcb fits its state-of-the-art production plant with the most recent technologies. In addition, the business has a stringent quality control system to guarantee that all goods meet the highest international standards.

The business has affordable costs and delivers top-notch customer support. Contacting the customer support department through phone or email is an option. The crew is always available to answer any questions you may have.

Ascent Circuits

Established in 2006, Ascent Circuits is a maker of printed circuit boards specialized in HDI rigid-flex PCBs.

Ascent Circuits has its headquarters in San Diego, California, and its production site is in Tijuana, Mexico.

The HDI rigid-flex PCBs manufactured by Ascent Circuits suit various applications, including medical devices, aerospace & defense, and industrial. HDI rigid-flex PCBs from Ascent Circuits comprise several materials, including FR4, polyimide, and Rogers.

Ascent Circuits’ HDI rigid-flex PCBs employ a technique that combines the most advantageous characteristics of rigid and flexible PCBs. As a result, HDI rigid-flex PCBs from Ascent Circuits are more flexible than rigid PCBs and more robust than flex PCBs.

HDI rigid-flex PCBs from Ascent Circuits are available in various sizes and forms. In addition, HDI rigid-flex PCBs from Ascent Circuits are easy to customize to fit the unique requirements of your application. In addition, the company is ISO 9001:2008 and ISO 13485:2003 accredited.

A team of engineers with experience designing and fabricating HDI rigid-flex PCBs supports Ascent Circuits’ HDI rigid-flex PCBs. In addition, HDI rigid-flex PCBs from Ascent Circuits has an able team of customer care specialists ready to answer your questions and assist you with your HDI rigid-flex PCB project.

Ascent Circuits is a reliable supplier of HDI rigid-flex PCBs. The company has a track record of offering many industries high-quality HDI rigid-flex PCBs. Ascent Circuits is your one-stop shop for HDI rigid-flex printed circuit boards (PCBs).

MultiTech Corporation

High-density interconnects (HDI) rigid-flex printed circuit boards are MultiTech Corporation’s specialty (PCBs). Additionally, the company’s products are helpful in many fields, including aerospace, defense, medicine, and industry. There are various ways in which HDI rigid-flex PCBs excel above conventional PCBs, including increased density, enhanced signal integrity, and improved mechanical stability.

MultiTech has been making HDI rigid-flex PCBs for more than 30 years. Their wares suit various contexts, from airplanes and spacecraft to missiles and medical equipment. As a result, they are versatile and can tailor a board to your precise specifications.

Additionally, MultiTech can boast the ISO 9001 and AS9100 quality management system certifications. Furthermore, they are involved with the IPC, the Association for the Advancement of Connected Electronics Industries.

Conclusion

With their high-density interconnects and flexible designs, HDI rigid-flex PCBs are an excellent option for many electrical projects with limited space. The performance and dependability are just as outstanding as standard PCBs but are also considerably more adaptable. Additionally, this paves the way for its application in fields as diverse as aviation, medicine, and the car industry. The above details have given a clear understanding of HDI rigid-flex PCBs. Notably, they come with a vast array of benefits besides some demerits. The manufacturing procedure is also equally crucial for our performance. In addition, the following information outlines the five most famous HDI rigid flex PCB manufacturers. In conclusion, with the above details, you can now choose the best manufacturer for your PCB solution.

Comments are closed