Circuit board laminate materials are a crucial component of electronic devices. These materials serve as the foundation for the circuitry that makes up the electronic device, providing support and insulation for the electrical components. The quality and durability of the laminate material directly impact the performance and lifespan of the electronic device.

There are several types of circuit board laminate materials available on the market, each with its own unique properties and advantages. The most common types of laminate materials include FR-4, polyimide, and Rogers. FR-4 is a flame-retardant material that is widely used in consumer electronics, while polyimide is known for its high-temperature resistance and flexibility. Rogers laminates, on the other hand, are designed for high-frequency applications and offer exceptional signal integrity.

Types of Circuit Board Laminate Materials

When it comes to circuit board laminate materials, there are several types available in the market. Each of these materials has its own unique properties and characteristics that make them suitable for different applications. In this section, we will discuss the most common types of circuit board laminate materials, including FR-4, Polyimide, PTFE, and Ceramic.

FR-4

FR-4 is a popular type of circuit board laminate material. It is made from woven fiberglass cloth and epoxy resin. FR-4 is known for its high strength, low cost, and excellent electrical properties. It is commonly used in applications that require high-performance and reliability, such as aerospace, military, and medical devices.

Polyimide

Polyimide is a flexible circuit board laminate material that is known for its high-temperature resistance and excellent electrical properties. It is made from a polymer film that is coated with a layer of copper. Polyimide is commonly used in applications that require flexibility, such as wearable devices, medical devices, and aerospace applications.

PTFE

PTFE (Polytetrafluoroethylene) is a circuit board laminate material that is known for its low dielectric constant and high-temperature resistance. It is commonly used in applications that require high-frequency performance, such as microwave and RF applications. PTFE is also used in high-speed digital applications due to its low signal loss and excellent electrical properties.

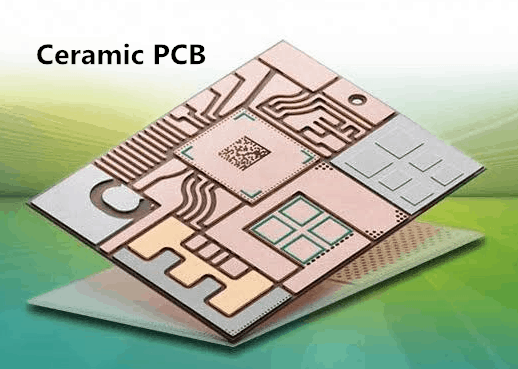

Ceramic

Ceramic is a circuit board laminate material that is known for its high-temperature resistance and excellent electrical properties. It is commonly used in applications that require high-frequency performance, such as microwave and RF applications. Ceramic is also used in high-power applications due to its excellent thermal properties.

In conclusion, there are several types of circuit board laminate materials available in the market, each with its own unique properties and characteristics. It is important to choose the right material for your specific application to ensure high performance and reliability.

Properties of Circuit Board Laminate Materials

Dielectric Constant

The dielectric constant is an important property of circuit board laminate materials. It is a measure of the ability of a material to store electrical energy in an electric field. A high dielectric constant means that a material can store more electrical energy than a material with a low dielectric constant. This property is important for the design of high-frequency circuits.

Thermal Conductivity

Thermal conductivity is the ability of a material to conduct heat. It is an important property for circuit board laminate materials because it affects the heat dissipation of the circuit board. A material with high thermal conductivity can dissipate heat more efficiently than a material with low thermal conductivity.

Moisture Absorption

Moisture absorption is the amount of water a material can absorb from the environment. It is an important property for circuit board laminate materials because moisture can affect the electrical properties of the circuit board. A material with high moisture absorption can be more susceptible to damage from moisture.

Flammability

Flammability is the ability of a material to burn. It is an important property for circuit board laminate materials because circuit boards can generate heat and can be a fire hazard if the material is flammable. A material with high flammability can be a safety hazard.

In summary, the properties of circuit board laminate materials are important for the design and performance of circuit boards. Dielectric constant, thermal conductivity, moisture absorption, and flammability are key properties to consider when selecting a circuit board laminate material.

Selection Criteria for Circuit Board Laminate Materials

When selecting circuit board laminate materials, there are several criteria that must be considered. These criteria include application requirements, environmental factors, cost considerations, and manufacturing process.

Application Requirements

The application requirements for circuit board laminate materials include electrical, mechanical, and thermal properties. Electrical properties such as dielectric constant, loss tangent, and breakdown voltage are critical for signal integrity. Mechanical properties such as tensile strength, flexural strength, and coefficient of thermal expansion are important for reliability. Thermal properties such as thermal conductivity and coefficient of thermal expansion are crucial for heat dissipation.

Environmental Factors

Environmental factors such as temperature, humidity, and chemical exposure can affect the performance and reliability of circuit board laminate materials. It is important to select materials that can withstand the environmental conditions of the application. For example, if the circuit board will be exposed to high temperatures, materials with high glass transition temperature should be selected.

Cost Considerations

Cost is always a consideration when selecting circuit board laminate materials. The cost of the material should be balanced with the performance and reliability requirements of the application. It is important to consider the total cost of ownership, which includes not only the cost of the material but also the cost of manufacturing, testing, and maintenance.

Manufacturing Process

The manufacturing process of circuit board laminate materials is also an important consideration. Some materials may require special handling or processing, which can increase the cost and complexity of manufacturing. It is important to select materials that can be easily processed using standard manufacturing techniques.

In summary, when selecting circuit board laminate materials, it is important to consider the application requirements, environmental factors, cost considerations, and manufacturing process. By carefully considering these criteria, the best material can be selected for the specific application.

Current Trends in Circuit Board Laminate Materials

High-Frequency Materials

High-frequency materials are becoming increasingly popular in the circuit board industry. These materials are designed to meet the demands of high-speed digital and RF applications. They offer low dielectric loss, high thermal stability, and excellent signal integrity. Some of the commonly used high-frequency materials include PTFE-based materials, ceramic-filled hydrocarbon materials, and liquid crystal polymer materials.

Eco-Friendly Materials

Eco-friendly materials are gaining traction in the circuit board industry due to the increasing concern for the environment. These materials are made from renewable resources and are biodegradable. They offer a low environmental impact and are free from hazardous substances. Some of the commonly used eco-friendly materials include bio-based epoxy resins, recycled paper phenolic materials, and soy-based materials.

Flexible Materials

Flexible materials are becoming increasingly popular in the circuit board industry due to their ability to bend and twist without breaking. They offer a high degree of flexibility, durability, and reliability. They are commonly used in applications such as wearable devices, medical devices, and automotive electronics. Some of the commonly used flexible materials include polyimide films, liquid crystal polymer films, and polyester films.

In summary, the circuit board industry is witnessing a shift towards high-frequency, eco-friendly, and flexible materials. These materials offer a range of benefits and are designed to meet the demands of modern electronic applications.

Comments are closed