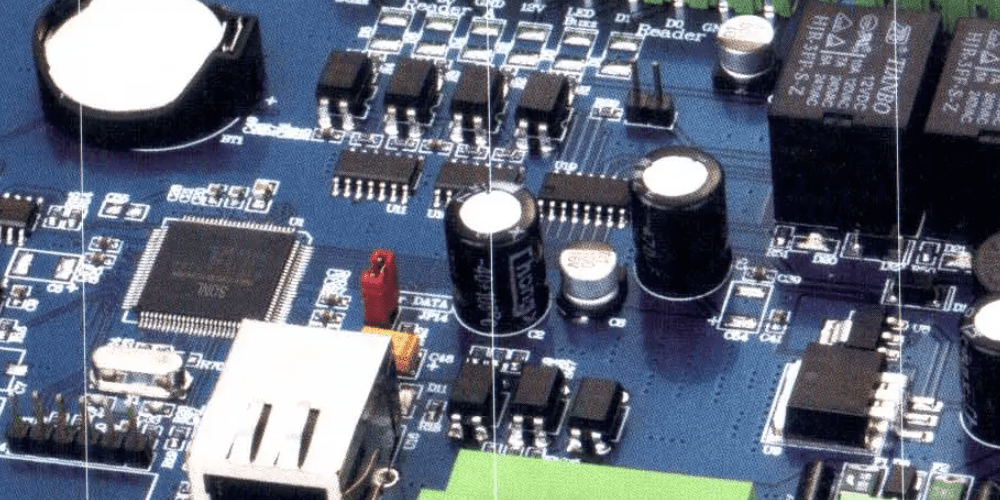

Central printed circuit board (PCB) is a critical component of modern electronic devices. It serves as the backbone of the device, connecting various components and ensuring their proper functioning. The PCB is a thin board made of insulating material, with conductive pathways etched onto it. These pathways connect the various electronic components of the device, such as microchips, capacitors, resistors, and transistors.

The central PCB plays a crucial role in the overall performance of the electronic device. It not only connects the components but also ensures that they work together seamlessly. The PCB design is critical to the performance of the device, as it determines the placement and routing of the components. A well-designed PCB can improve the device’s performance, reduce its power consumption, and enhance its reliability. Therefore, it is essential to have a high-quality central PCB in any electronic device.

What is a Central Printed Circuit Board?

A Central Printed Circuit Board (CPCB) is a type of printed circuit board that is used to connect and control various components of a device or system. It is also known as a motherboard or mainboard. The CPCB is responsible for transmitting data and power between different parts of the device, as well as managing the overall operation of the system.

The CPCB is typically located at the center of the device or system, hence the name “central.” It is designed to be the main hub for all other components, including the processor, memory, and input/output devices. The CPCB is responsible for managing the flow of data and power between these components, as well as ensuring that they are all working together properly.

One of the key advantages of using a CPCB is that it allows for a high degree of customization and flexibility. Different components can be connected and configured in a variety of ways, depending on the specific needs of the device or system. This makes it possible to create highly specialized and tailored systems that are optimized for specific tasks or applications.

Overall, the CPCB is a critical component of many modern devices and systems, providing the backbone for their operation and functionality. Its importance cannot be overstated, and it is essential for anyone working in the field of electronics to have a solid understanding of its capabilities and limitations.

Key Components of a Central Printed Circuit Board

When it comes to designing a central printed circuit board (PCB), there are several key components that must be considered. These components are essential to the functionality of the PCB, and each plays a unique role in ensuring that the device operates as intended.

Processor

The processor is the brain of the central PCB and is responsible for executing instructions and performing calculations. It is typically a microcontroller or microprocessor that is designed to handle the specific tasks required by the device. The processor is responsible for managing input and output, communicating with other components, and controlling the overall operation of the device.

Memory

Memory is used to store data and instructions that the processor needs to access quickly. There are two main types of memory used in central PCBs: volatile and non-volatile. Volatile memory, such as RAM, is used for temporary storage and is erased when the device is powered off. Non-volatile memory, such as flash memory, is used for long-term storage and retains its data even when the device is powered off.

Power Management

Power management is essential to ensure that the device operates efficiently and effectively. A power management system is responsible for regulating the voltage and current supplied to the various components of the PCB. This helps to prevent damage to the components and ensures that they operate within their specified parameters.

Connectivity

Connectivity is essential to allow the central PCB to communicate with other devices and systems. This can include wired and wireless connections, such as Ethernet, USB, Bluetooth, and Wi-Fi. The connectivity options chosen will depend on the specific requirements of the device and the intended use case.

In summary, the processor, memory, power management, and connectivity are key components of a central printed circuit board. Each plays a critical role in ensuring that the device operates as intended and meets the requirements of its intended use case.

Advantages of Central Printed Circuit Boards

Reduced System Complexity

Central Printed Circuit Boards (CPCBs) are designed to integrate multiple functions into a single board, which reduces the overall system complexity. This is because CPCBs can accommodate various components like microcontrollers, sensors, and communication modules, among others, on a single board. The integration of these components eliminates the need for multiple boards, cables, and connectors, reducing the space requirement and simplifying the wiring process.

Improved Reliability

CPCBs are designed to enhance the reliability of electronic systems. This is because they are manufactured using advanced technologies that ensure high-quality and consistent performance. Additionally, the integration of components on a single board reduces the chances of failure due to loose connections, which is a common problem in traditional printed circuit boards. Furthermore, CPCBs undergo rigorous testing to ensure they meet the required standards, making them more reliable than traditional PCBs.

Reduced Power Consumption

CPCBs are designed to reduce power consumption in electronic systems. This is because they use advanced technologies that consume less power than traditional PCBs. Additionally, the integration of multiple components on a single board reduces the power consumption by eliminating the need for multiple boards, cables, and connectors. This results in a more efficient and cost-effective system.

Scalability

CPCBs are designed to be scalable, which means they can be easily expanded or modified to accommodate new components. This is because they are designed with extra space and connectors, allowing for easy integration of new components. Additionally, the use of advanced technologies in manufacturing CPCBs means that they can support high-speed communication protocols, making them suitable for use in high-performance electronic systems.

In conclusion, CPCBs offer several advantages over traditional printed circuit boards. These include reduced system complexity, improved reliability, reduced power consumption, and scalability. These advantages make CPCBs suitable for use in various electronic systems, including high-performance systems.

Applications of Central Printed Circuit Boards

Central Printed Circuit Boards (PCBs) are widely used in various industries due to their versatility and reliability. Let’s explore some of the applications of Central PCBs in different sectors.

Consumer Electronics

Central PCBs are extensively used in consumer electronics products such as smartphones, laptops, and tablets. These PCBs provide a compact and efficient solution for connecting various components of the device. Central PCBs also ensure that the device operates smoothly and without any glitches.

Industrial Automation

Central PCBs play a crucial role in industrial automation systems. They are used to control and monitor various processes in factories and plants. These PCBs are designed to withstand harsh environments and extreme temperatures, making them highly reliable and durable.

Medical Devices

Central PCBs are used in various medical devices such as MRI machines, X-ray machines, and patient monitoring systems. These PCBs are designed to meet the strict safety and quality standards required in the medical industry. They ensure that the medical devices operate accurately and reliably, providing critical information to healthcare professionals.

Automotive

Central PCBs are also used in the automotive industry. They are used in various components of the car, including the engine control unit, infotainment system, and safety features. These PCBs are designed to withstand the harsh environment of a car, including extreme temperatures, vibrations, and shock.

In conclusion, Central PCBs are an essential component in various industries due to their versatility and reliability. They provide a compact and efficient solution for connecting various components of a device, ensuring that it operates smoothly and without any glitches.

Future of Central Printed Circuit Boards

Central Printed Circuit Boards (PCBs) have come a long way since their inception. They are a critical component in most electronic devices, and their importance is only increasing as technology advances. Here are some of the future trends and developments in the world of Central PCBs.

Miniaturization

As technology evolves, electronic devices are becoming smaller and more compact. This trend is driving the need for smaller and more densely populated PCBs. Miniaturization is a significant challenge for PCB manufacturers, as it requires them to create smaller components without sacrificing functionality or reliability. However, advancements in manufacturing technologies and materials are making it possible to create smaller and more complex PCBs.

Flexibility

Flexible PCBs are gaining popularity in the electronics industry due to their ability to bend and twist. They are ideal for devices that require a high degree of flexibility, such as wearables and medical devices. Flexible PCBs are also more durable than traditional rigid PCBs, making them an attractive option for harsh environments.

Integration

Integration is the process of combining multiple components into a single PCB. This trend is gaining popularity due to its ability to reduce the size and weight of electronic devices while improving their functionality. Integrated PCBs are also more reliable and cost-effective than traditional PCBs.

5G Technology

5G technology is the next generation of wireless communication, and it is expected to revolutionize the electronics industry. 5G technology requires high-speed and high-frequency communication, which can only be achieved through the use of advanced PCBs. Central PCBs are expected to play a critical role in the development and implementation of 5G technology.

In conclusion, the future of Central PCBs is bright, with new trends and developments emerging every day. As technology continues to evolve, we can expect to see more miniaturization, flexibility, integration, and advancements in 5G technology.

Comments are closed