Ordering prototype PCBs can be a daunting task, especially for those who are new to the process. However, with the right information and guidance, it can be a seamless and straightforward experience. Prototype PCBs are small batches of circuit boards that are used for testing and validation purposes before moving on to full-scale production. They are an essential part of the design and development process, allowing engineers and designers to make necessary changes and improvements before investing in large-scale production.

When ordering prototype PCBs, there are several factors to consider, such as the board’s size, thickness, number of layers, and material. It is essential to choose a reliable and experienced manufacturer that can provide high-quality PCBs that meet your specific requirements. Additionally, it is crucial to ensure that the manufacturer can deliver the PCBs within your desired timeframe and budget. By taking these factors into account, you can ensure that your prototype PCBs are of the highest quality and meet your design and development needs.

What is a Prototype PCB?

Definition

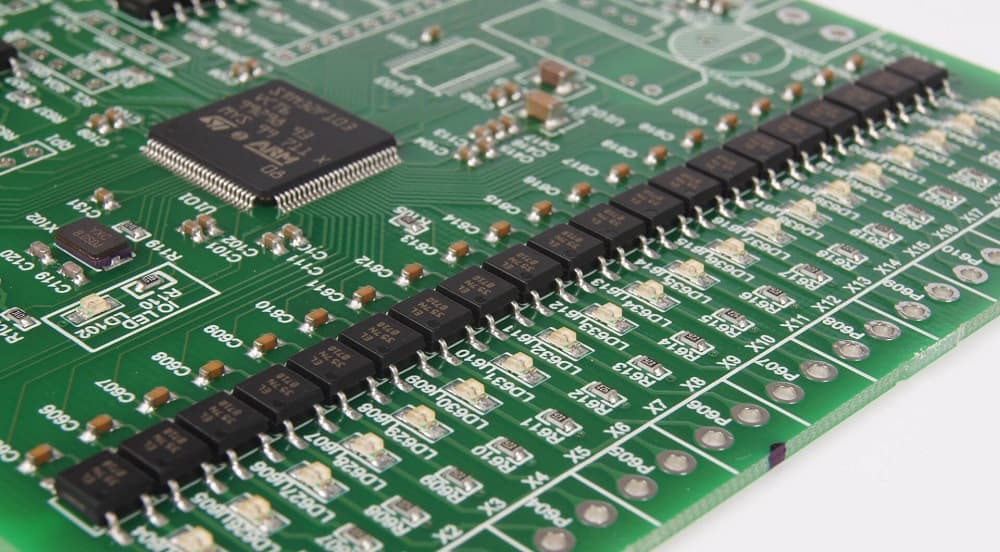

A Prototype PCB, or Printed Circuit Board, is a type of board used to connect electronic components. It is a thin board made of insulating material with conductive pathways etched onto its surface. The pathways connect electronic components such as resistors, capacitors, and diodes, allowing them to communicate and function as a cohesive unit.

Prototype PCBs are used to test and develop electronic designs before they are mass-produced. They are an essential tool for engineers and designers who need to test their designs and make modifications before finalizing the product.

Importance

Prototype PCBs are critical in the development of new electronic products. They allow engineers and designers to test and refine their designs, ensuring that the final product meets the required specifications. Without prototype PCBs, it would be difficult to identify design flaws, leading to costly errors in the final product.

Prototype PCBs are also essential for the rapid development of new products. They allow engineers and designers to quickly test and modify their designs, reducing the time it takes to bring a new product to market. This can be a significant advantage in industries where time-to-market is critical.

In summary, Prototype PCBs are an essential tool for engineers and designers. They allow for the testing and refinement of electronic designs, leading to better products and faster time-to-market.

Ordering Prototype PCBs

Choosing a Manufacturer

When selecting a manufacturer for your prototype PCB order, consider factors such as their pricing, lead times, and quality of work. Look for reviews and ratings from previous customers to get an idea of their reputation and reliability. It’s also important to ensure that the manufacturer can handle the specific requirements of your design, such as the number of layers and board size.

Preparing Your Design Files

Before placing your order, make sure your design files are ready and formatted correctly. Check that the files are in the correct format for the manufacturer you have chosen, and that they include all necessary information such as drill files and fabrication notes. It’s also a good idea to review your design for any errors or potential issues before submitting it.

Selecting Materials

When selecting materials for your prototype PCB, consider factors such as the intended use of the board, its operating environment, and any specific requirements for the design. Common materials for PCBs include FR-4, aluminum, and flexible materials such as polyimide. Be sure to discuss your material options with your manufacturer to ensure that you choose the best option for your specific project.

Placing Your Order

Once you have chosen a manufacturer, prepared your design files, and selected your materials, it’s time to place your order. Be sure to review your order carefully before submitting it to ensure that all details are correct. You may also want to discuss any specific requirements or concerns with your manufacturer before finalizing the order.

By following these steps and working with a reputable manufacturer, you can ensure a successful and efficient process for ordering prototype PCBs.

Manufacturing Process

Printing the Design

The first step in manufacturing a prototype PCB is to print the design onto the board. This is done using a special printer that can print the design onto the board with precision. The printer uses a special ink that is resistant to the etching process that will come later.

Etching the Board

After the design has been printed onto the board, the next step is to etch the board. This is done by placing the board into a special solution that will dissolve the copper that is not covered by the ink. This process leaves only the copper that is part of the design on the board.

Drilling Holes

Once the board has been etched, the next step is to drill the holes for the components. This is done using a special drill that can drill precise holes in the board. The drill is guided by the design that was printed onto the board.

Adding Components

The final step in manufacturing a prototype PCB is to add the components. This is done by placing the components onto the board and soldering them in place. This process requires a steady hand and a careful eye to ensure that the components are placed in the correct location and that the solder joints are strong and secure.

Overall, the manufacturing process for a prototype PCB is a complex and precise process that requires specialized equipment and skilled technicians. However, with the right tools and expertise, it is possible to create high-quality prototype PCBs that can be used for a variety of applications.

Quality Control

Inspection and Testing

Before shipping, every prototype PCB goes through a rigorous inspection process to ensure that the quality meets the highest standards. The inspection process includes visual inspection, automated optical inspection (AOI), and X-ray inspection. The visual inspection checks for any visible defects such as scratches, cracks, or broken components. AOI checks for defects in soldering, component placement, and other parameters. X-ray inspection is used to check for hidden defects such as solder bridges, voids, and misalignments.

After the inspection, the PCBs go through a series of tests to ensure that they meet the required specifications. The tests include electrical testing, functional testing, and environmental testing. Electrical testing checks for any electrical faults such as short circuits, open circuits, or incorrect values. Functional testing checks if the PCB performs as expected under different conditions. Environmental testing checks if the PCB can withstand different environmental conditions such as temperature, humidity, and vibration.

Certifications

We understand the importance of certifications in the electronics industry. That’s why we ensure that our prototype PCBs meet the necessary certifications such as RoHS, UL, and ISO. RoHS certification ensures that the PCBs are free from hazardous substances such as lead, mercury, and cadmium. UL certification ensures that the PCBs meet the safety standards required for electrical products. ISO certification ensures that our processes meet the highest quality standards.

In conclusion, our quality control process ensures that every prototype PCB we ship meets the highest quality standards. We use the latest inspection and testing techniques to ensure that the PCBs are defect-free and perform as expected. We also ensure that our PCBs meet the necessary certifications to give our customers peace of mind.

Cost Considerations

When it comes to ordering prototype PCBs, cost is an important factor to consider. Here are some factors that can affect the cost of your order:

Factors Affecting Cost

- Board size: Larger boards will generally cost more than smaller ones.

- Layer count: The more layers your board has, the more expensive it will be.

- Material: Certain materials, such as high-frequency materials, can be more expensive than others.

- Turnaround time: If you need your boards quickly, you may have to pay extra for expedited manufacturing and shipping.

Tips for Saving Money

While there are some factors that you can’t change, there are some things you can do to save money on your prototype PCB order:

- Optimize your design: Make sure your design is as efficient as possible to minimize the size and layer count of your board.

- Choose standard materials: Using standard materials can help keep costs down.

- Plan ahead: If you have a flexible timeline, you can save money by choosing a longer turnaround time for your order.

By considering these factors and following these tips, you can help keep the cost of your prototype PCB order under control.

Comments are closed