Printed circuit boards (PCBs) are a crucial component of modern electronics. They are used in everything from smartphones to cars to medical equipment. Understanding PCBs is essential for anyone working with electronics or looking to learn more about how they work.

A PCB is a board made of insulating material, such as fiberglass or plastic, with conductive pathways etched onto its surface. These pathways connect the various components on the board, such as resistors, capacitors, and microchips. PCBs are designed to be compact, durable, and efficient, allowing for complex electronic circuits to be built in a small space.

To understand PCBs, it is important to have a basic understanding of electronics. This includes knowledge of electrical components, such as resistors, capacitors, and diodes, as well as an understanding of how circuits work. With this knowledge, you can begin to understand how PCBs are designed, how they function, and how to troubleshoot problems that may arise.

What are Printed Circuit Boards?

Printed Circuit Boards (PCBs) are the backbone of modern electronics. They are thin boards made of insulating materials, such as fiberglass, with copper conductive pathways etched onto their surface. These pathways connect the electronic components on the board, allowing them to communicate and work together.

Composition of PCBs

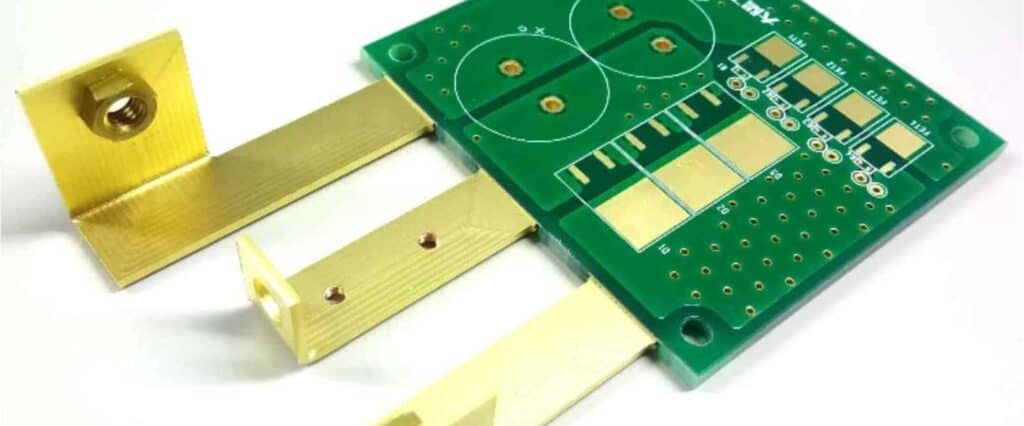

PCBs are made up of several layers of different materials. The most common PCBs have four layers: a substrate layer, a copper layer, a solder mask layer, and a silkscreen layer. The substrate layer is usually made of fiberglass or some other insulating material. The copper layer is where the conductive pathways are etched. The solder mask layer is a protective layer that covers the copper layer and helps prevent short circuits. The silkscreen layer is where text and graphics are printed to help identify components.

Types of PCBs

There are several types of PCBs, each designed for different purposes. Some common types include:

- Single-sided PCBs: These have conductive pathways on only one side of the board.

- Double-sided PCBs: These have pathways on both sides of the board.

- Multi-layer PCBs: These have several layers of conductive pathways, allowing for more complex circuits.

- Flexible PCBs: These are made of flexible materials, allowing them to bend and twist. They are often used in applications where space is limited.

PCBs have revolutionized the electronics industry, allowing for smaller, more complex devices. Understanding the basics of PCBs is essential for anyone interested in electronics.

Designing Printed Circuit Boards

Schematic Design

When designing a printed circuit board (PCB), the first step is to create a schematic. This is a diagram that shows how the components of the circuit are connected. The schematic should be clear and easy to read, with each component labeled and connected by lines that indicate the flow of current.

It is important to carefully consider the placement of components in the schematic, as this will affect the layout of the PCB. Grouping components by function or location can make the layout process easier.

PCB Layout Design

Once the schematic is complete, the next step is to design the layout of the PCB. This involves placing the components on the board and routing the connections between them.

When designing the layout, it is important to consider factors such as the size and shape of the board, the placement of connectors and mounting holes, and the need for ground planes or signal traces.

Using software tools can make the layout process easier and more efficient. These tools can help with tasks such as component placement, automatic routing, and design rule checking.

Overall, designing a printed circuit board requires careful planning and attention to detail. By following best practices for schematic and layout design, it is possible to create a high-quality PCB that meets the needs of your project.

Manufacturing Printed Circuit Boards

Printed Circuit Board Assembly

Printed Circuit Board Assembly (PCBA) is the process of assembling electronic components onto a printed circuit board. The process involves the following steps:

- Solder paste application: The solder paste is applied to the board using a stencil.

- Component placement: The components are placed onto the board using a pick-and-place machine.

- Reflow soldering: The board is heated in a reflow oven to melt the solder paste and form a permanent bond between the components and the board.

PCB Testing

PCB testing is an essential part of the manufacturing process. The testing process involves the following steps:

- Visual inspection: The board is inspected visually for any defects such as scratches, cracks, or misaligned components.

- Electrical testing: The board is tested for electrical continuity and functionality using a test fixture.

- Functional testing: The board is tested in an actual application to ensure that it functions as intended.

PCB Inspection

PCB inspection is done to ensure that the boards meet the required quality standards. The inspection process involves the following steps:

- Automated optical inspection: The board is inspected using an automated optical inspection machine to detect any defects such as missing components, misaligned components, or solder bridging.

- X-ray inspection: The board is inspected using X-rays to detect any hidden defects such as voids in the solder joints or cracks in the components.

- Manual inspection: The board is inspected manually by a trained technician to detect any defects that were not detected by the automated inspection machines.

In conclusion, the manufacturing of printed circuit boards involves several complex processes that require specialized equipment and skilled technicians. The quality of the PCBs is critical to the performance of the electronic devices they are used in. Therefore, it is essential to follow the necessary manufacturing processes and testing procedures to ensure that the PCBs meet the required quality standards.

Applications of Printed Circuit Boards

Printed circuit boards (PCBs) are used in a wide range of electronic devices and systems. They are an essential component in the design and manufacturing of electronic products. PCBs are used in various industries, including consumer electronics, medical devices, and the automotive industry.

Consumer Electronics

Consumer electronics, such as smartphones, tablets, and laptops, rely heavily on PCBs. PCBs are used to connect the various components of these devices, including the processor, memory, and display. PCBs are also used in televisions, sound systems, and gaming consoles. The use of PCBs in consumer electronics has led to smaller and more compact devices that are easier to use and transport.

Medical Devices

PCBs are used in a wide range of medical devices, including pacemakers, MRI machines, and dialysis machines. PCBs are used to connect sensors, processors, and other components in these devices. PCBs are also used in medical implants, such as cochlear implants and artificial joints. The use of PCBs in medical devices has led to more accurate and effective treatments for patients.

Automotive Industry

PCBs are used in a wide range of automotive applications, including engine control units, airbag systems, and entertainment systems. PCBs are used to connect sensors, processors, and other components in these systems. PCBs are also used in electric and hybrid vehicles to control the flow of electricity. The use of PCBs in the automotive industry has led to more efficient and reliable vehicles.

In conclusion, PCBs are an essential component in the design and manufacturing of electronic products. PCBs are used in a wide range of industries, including consumer electronics, medical devices, and the automotive industry. The use of PCBs has led to smaller, more compact devices, more accurate and effective medical treatments, and more efficient and reliable vehicles.

Comments are closed