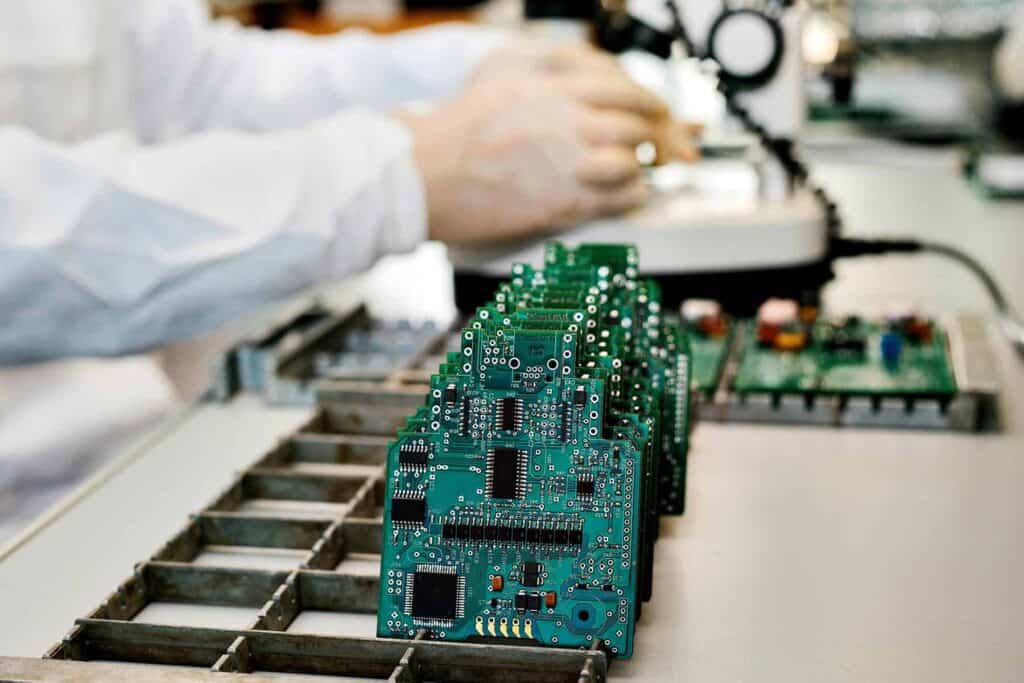

Printed circuit boards (PCBs) are the backbone of every electronic device, and their quality and reliability are crucial for the smooth functioning of the device. With the increasing demand for electronic devices, the demand for high-quality PCBs has also surged. As a result, the PCB manufacturing industry has witnessed significant growth in recent years.

To help you choose the best PCB manufacturer for your needs, we have compiled a list of the top 10 printed circuit board manufacturers. Our list is based on factors such as the company’s reputation, experience, quality of products, and customer service. We have also taken into consideration the company’s certifications and accreditations, as well as their ability to provide custom solutions to meet specific requirements.

Whether you are a hobbyist looking for a small batch of PCBs or a large corporation in need of high-volume production, our list has something for everyone. So, without further ado, let’s dive into the top 10 printed circuit board manufacturers and find out what makes them stand out in the industry.

Top 10 Printed Circuit Board Manufacturers

1. Company A

Company A is a leading manufacturer of printed circuit boards, offering a wide range of products and services to meet the needs of customers in various industries. They specialize in high-quality, high-reliability PCBs for applications in aerospace, defense, medical, and other industries.

2. Company B

Company B is another top manufacturer of printed circuit boards, with a focus on providing customized solutions to meet the specific needs of customers. They offer a wide range of PCBs, including single-sided, double-sided, and multi-layer boards, as well as flexible and rigid-flex boards.

3. Company C

Company C is a well-known manufacturer of high-quality, high-reliability PCBs for use in a variety of industries, including aerospace, defense, medical, and more. They offer a range of products and services, including design and engineering, prototyping, and volume production.

4. Company D

Company D is a leading provider of printed circuit boards for use in a variety of applications, including consumer electronics, automotive, and industrial. They offer a wide range of PCBs, including single-sided, double-sided, and multi-layer boards, as well as flexible and rigid-flex boards.

5. Company E

Company E is a well-established manufacturer of printed circuit boards, with a focus on providing high-quality products and services to customers in various industries. They offer a range of PCBs, including high-density interconnect (HDI) boards, flexible and rigid-flex boards, and more.

6. Company F

Company F is a leading manufacturer of printed circuit boards for use in a variety of industries, including aerospace, defense, medical, and more. They offer a range of products and services, including design and engineering, prototyping, and volume production.

7. Company G

Company G is a well-known manufacturer of high-quality, high-reliability PCBs for use in a variety of industries, including aerospace, defense, medical, and more. They offer a range of products and services, including design and engineering, prototyping, and volume production.

8. Company H

Company H is a leading provider of printed circuit boards for use in a variety of applications, including consumer electronics, automotive, and industrial. They offer a wide range of PCBs, including single-sided, double-sided, and multi-layer boards, as well as flexible and rigid-flex boards.

9. Company I

Company I is a well-established manufacturer of printed circuit boards, with a focus on providing high-quality products and services to customers in various industries. They offer a range of PCBs, including high-density interconnect (HDI) boards, flexible and rigid-flex boards, and more.

10. Company J

Company J is a leading manufacturer of printed circuit boards for use in a variety of industries, including aerospace, defense, medical, and more. They offer a range of products and services, including design and engineering, prototyping, and volume production.

Factors to Consider When Choosing a Printed Circuit Board Manufacturer

When it comes to choosing a printed circuit board (PCB) manufacturer, there are several factors to consider. Here are some key considerations to keep in mind:

1. Quality Standards

One of the most important factors to consider when choosing a PCB manufacturer is their quality standards. Look for a manufacturer that adheres to industry standards such as ISO 9001, UL, and IPC-A-600. These certifications ensure that the manufacturer follows strict quality control measures and produces PCBs that meet or exceed industry standards.

2. Manufacturing Capabilities

Another important factor to consider is the manufacturer’s manufacturing capabilities. Look for a manufacturer that offers a wide range of PCB types, materials, and thicknesses. Also, consider their production capacity, lead times, and ability to handle complex designs.

3. Customer Support

Customer support is also an important consideration. Look for a manufacturer that provides excellent customer service, including technical support, design assistance, and responsive communication. Consider their availability and responsiveness to your inquiries, as well as their ability to provide timely and accurate quotes.

4. Pricing and Lead Time

Finally, pricing and lead time are important factors to consider. Look for a manufacturer that offers competitive pricing without sacrificing quality. Also, consider their lead times and ability to meet your production schedule.

In summary, when choosing a PCB manufacturer, consider their quality standards, manufacturing capabilities, customer support, pricing, and lead time. By carefully evaluating these factors, you can choose a manufacturer that meets your needs and produces high-quality PCBs.

Industry Trends and Future Outlook

Increasing Demand for Flex PCBs

The demand for flexible printed circuit boards (PCBs) has been on the rise in recent years. Flex PCBs offer several advantages over traditional rigid PCBs, including increased durability, space-saving capabilities, and the ability to bend and twist. They are commonly used in industries such as consumer electronics, medical devices, and automotive.

Growing Popularity of IoT Devices

With the increasing popularity of the Internet of Things (IoT), the demand for PCBs used in IoT devices has also been growing. IoT devices require PCBs that are small, lightweight, and energy-efficient. This has led to the development of new technologies and materials that can meet these requirements.

Advancements in Technology and Materials

Advancements in technology and materials have also been driving the growth of the PCB industry. New materials such as flexible substrates, conductive inks, and advanced laminates have been developed to meet the demands of modern applications. Additionally, new manufacturing processes such as additive manufacturing and 3D printing are being used to produce PCBs with greater precision and efficiency.

Impact of COVID-19 Pandemic

The COVID-19 pandemic had a significant impact on the PCB industry. Supply chain disruptions, factory closures, and reduced demand for certain products led to a decline in production and sales. However, the industry has been recovering as the global economy begins to rebound.

Overall, the PCB industry is expected to continue growing in the coming years, driven by advancements in technology, increasing demand for flexible and IoT devices, and the recovery from the COVID-19 pandemic.

Comments are closed