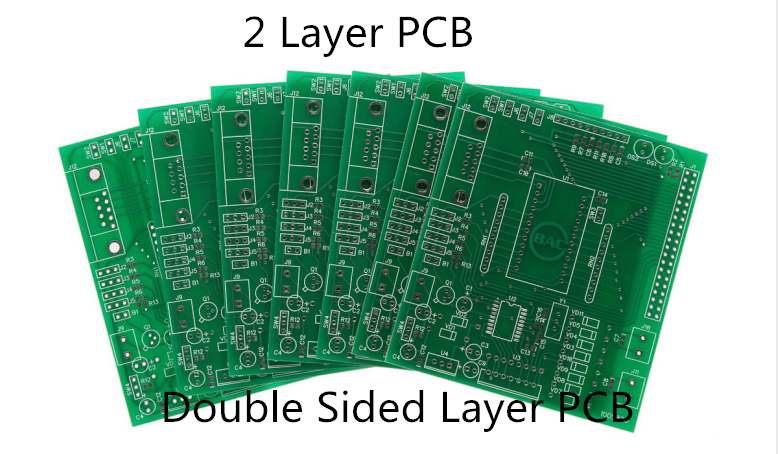

A two-layer circuit board is a type of printed circuit board (PCB) that consists of two conductive layers separated by a non-conductive layer. This type of PCB is commonly used in electronic devices due to its simplicity and cost-effectiveness. Compared to multi-layer PCBs, two-layer PCBs are easier to design and manufacture, making them a popular choice for small to medium-sized electronic products.

The two-layer PCB design consists of a top layer and a bottom layer, with the non-conductive layer (also known as the substrate) sandwiched in between. The conductive layers are typically made of copper, which is etched to create the desired circuit pattern. The non-conductive layer is usually made of a fiberglass-reinforced epoxy resin, which provides mechanical support and insulation between the conductive layers. Two-layer PCBs are commonly used in applications such as power supplies, consumer electronics, and automotive electronics.

What is a 2 Layer Circuit Board?

Definition

A 2 Layer Circuit Board is a type of printed circuit board (PCB) that consists of two layers of conductive material separated by an insulating layer. It is one of the most commonly used types of PCBs due to its simplicity and cost-effectiveness. The conductive layers are usually made of copper, while the insulating layer is made of a non-conductive material such as fiberglass or epoxy resin.

Design Considerations

When designing a 2 Layer Circuit Board, there are several considerations that must be taken into account. These include:

- Size: The size of the board must be carefully considered to ensure that it fits within the device it will be used in.

- Trace Width: The width of the traces on the board must be chosen based on the amount of current that will be flowing through them.

- Component Placement: The placement of components on the board must be carefully planned to ensure that they are positioned correctly and do not interfere with each other.

- Signal Integrity: The design must take into account the signal integrity of the board to ensure that there is no interference or crosstalk between signals.

Overall, a 2 Layer Circuit Board is a simple and cost-effective solution for many electronic devices. Its design considerations must be taken into account to ensure that it functions correctly and reliably.

How is a 2 Layer Circuit Board Made?

Materials

The materials used in a 2 layer circuit board include a substrate, copper, and a solder mask. The substrate is typically made of fiberglass or some other non-conductive material. Copper is used to create the conductive pathways on the board. The solder mask is used to protect the copper traces from oxidation and to prevent solder from flowing where it is not intended.

Fabrication Process

The fabrication process for a 2 layer circuit board involves multiple steps. First, the substrate is cleaned and coated with a layer of copper. Then, a layer of photoresist is applied to the copper. The photoresist is exposed to UV light through a mask that defines the pattern of the copper traces. The unexposed photoresist is then removed, leaving behind a pattern of photoresist that protects the copper in the areas where the traces will be.

Next, the exposed copper is etched away using an acid solution. The remaining photoresist is then removed, leaving behind the copper traces. A second layer of copper is then applied to the other side of the substrate, and the same process is repeated to create the second layer of traces.

Finally, the solder mask is applied to the board. The solder mask is applied using a screen-printing process, where the mask is applied only to the areas where it is needed. The board is then heated to cure the solder mask, completing the fabrication process.

Overall, the process of creating a 2 layer circuit board is complex and requires specialized equipment and expertise. However, it is a critical component in the creation of many electronic devices and is essential to the advancement of technology.

Advantages of 2 Layer Circuit Boards

Cost-Effective

One of the main advantages of 2 layer circuit boards is that they are cost-effective. They are cheaper to produce than multilayer PCBs, which require more materials and time to manufacture. This makes them an ideal choice for low-cost applications.

2 layer circuit boards also require fewer components, which further reduces the overall cost of the circuit board. The simplicity of the design means that the board can be produced quickly and efficiently, which also helps to keep costs down.

Ease of Design

Another advantage of 2 layer circuit boards is that they are easy to design. The simplicity of the design means that they can be produced quickly and efficiently, which is ideal for small-scale production runs.

The design process for 2 layer circuit boards is also easier than for multilayer PCBs. There are fewer layers to consider, which makes it easier to create a clear and concise design. This makes them a popular choice for hobbyists and small businesses who may not have the resources to design complex multilayer PCBs.

In addition, 2 layer circuit boards are easier to troubleshoot and repair. The simplicity of the design means that it is easier to identify and fix any issues that may arise.

Overall, 2 layer circuit boards offer a cost-effective and easy-to-design solution for low-cost applications.

Disadvantages of 2 Layer Circuit Boards

Limited Functionality

One of the main disadvantages of 2 layer circuit boards is their limited functionality. These circuit boards only have two layers of conductive material, which means that they have a limited capacity for routing traces and components. This can be a problem for complex circuits, as there may not be enough space to fit all of the necessary components.

Difficult to Repair

Another disadvantage of 2 layer circuit boards is that they can be difficult to repair. If a trace or component fails, it can be difficult to determine the cause of the problem and to fix it. In some cases, it may be necessary to replace the entire circuit board, which can be expensive and time-consuming.

In addition, the limited space on a 2 layer circuit board can make it difficult to access and repair components. This can be especially problematic if the circuit board is located in a hard-to-reach area or if there are other components in the way.

Overall, while 2 layer circuit boards can be a cost-effective solution for simple circuits, they may not be suitable for more complex designs. It is important to carefully consider the needs of your circuit before deciding on a 2 layer circuit board.

Applications of 2 Layer Circuit Boards

Consumer Electronics

2 layer circuit boards are commonly used in consumer electronics such as smartphones, laptops, and tablets. These circuit boards are ideal for low power devices and can be used to create complex circuits that require a small form factor. In addition, 2 layer circuit boards are cost-effective and can be produced in large quantities, making them an ideal choice for high-volume production.

Some of the common consumer electronics applications of 2 layer circuit boards include:

- Mobile devices: 2 layer circuit boards are commonly used in smartphones, tablets, and other mobile devices due to their small size and low power consumption.

- Audio and video equipment: 2 layer circuit boards are used in audio and video equipment such as televisions, speakers, and headphones to create complex circuits that deliver high-quality sound and video.

- Gaming consoles: 2 layer circuit boards are used in gaming consoles to create complex circuits that deliver high-quality graphics and sound.

Industrial Automation

2 layer circuit boards are also commonly used in industrial automation applications. These circuit boards are ideal for creating complex circuits that can control machinery and other equipment. In addition, 2 layer circuit boards can be produced in large quantities, making them an ideal choice for industrial automation applications that require high-volume production.

Some of the common industrial automation applications of 2 layer circuit boards include:

- Robotics: 2 layer circuit boards are used in robotics to create complex circuits that can control the movement and actions of robots.

- Industrial control systems: 2 layer circuit boards are used in industrial control systems to create complex circuits that can control machinery and other equipment.

- Medical equipment: 2 layer circuit boards are used in medical equipment such as MRI machines and ultrasound machines to create complex circuits that deliver high-quality imaging and other functions.

Overall, 2 layer circuit boards are a versatile and cost-effective solution for a wide range of applications in consumer electronics and industrial automation.

Comments are closed