PCBs form the heart of different electronics. They can be found in simple products such as calculators as well as advanced satellite and military systems. Do you, however, know ways of assembling a PCB? Also, do you understand the steps in the procedure?

You don’t have to worry if you do not understand the process. We created this comprehensive guide on a professional PCB Assembly in order to ensure you comprehend the whole and entire process. By so, then you may assemble the PCB and bring your project to life. For the purpose of this article, we’ll look at the process of professional PCB assembly and the various technologies that are used for it.

Assembly of Printed Circuit Boards

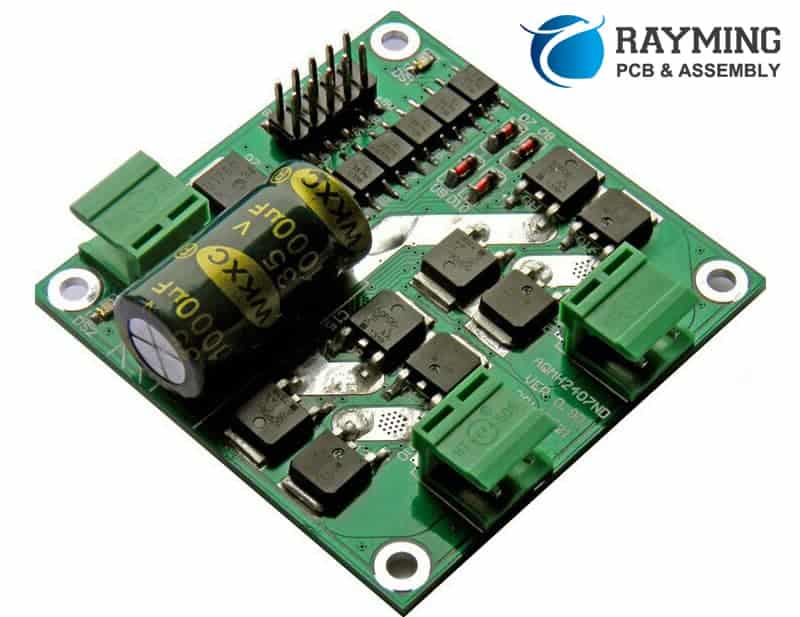

Professional PCB assembly is the process of placing or mounting electronic components, which allow the board to function. The electronic component can be mounted manually or automatically, and then soldered properly.

This would be helpful if you didn’t mix it up with PCB manufacturing that creates prototypes. The installing of electronic component during the process of assembly. The professional pcb assembly is a circuit board that is displayed after all of the pieces and parts have been soldered and properly installed.

A PCB can be assembled using a variety of technologies, including THT and SMT processes. We’ll go over them in depth later, but now, let’s focus on PCB design.

Design and Fabrication of Printed Circuit Boards

You can design PCBs using schematics and a CAD solution. The Gerber files or design files are handed to the manufacturer that manufactures the PCB.

PCBs have a basic design that includes-

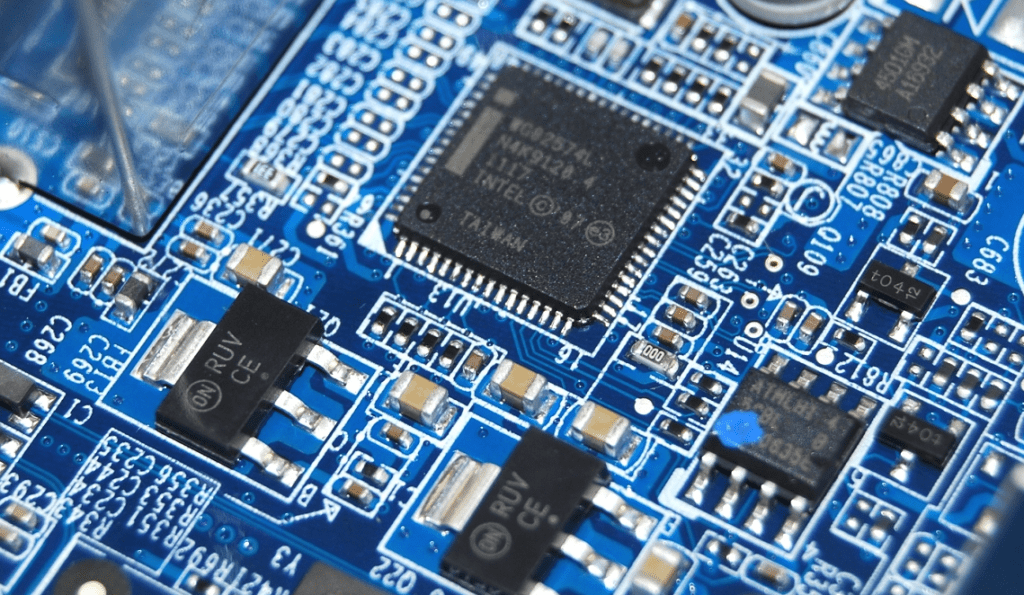

Substrate: The substrate is a PCB’s base material. It is responsible for the board’s rigidity and durability.

Copper: A thin and conductive layer of copper is applied to each functional side of the PCB. Depending on if the circuit board is double or single-sided, the number of sides will necessitate a copper layer.

Silkscreen: As the final PCB layer, use the white screen. It contains labels for various components present in characters and symbols.

Solder Mask: This is the green substance on the PCBs is caused by the use of a solder mask. Also, it insulates the traces of copper to ensure they don’t come into contact with conductive components.

Process of Professional PCB Assembly

The PCBA process is as follows. While there is no standard method, here are five PCBA methods:

Stenciling with Solder Paste

This entails applying solder paste onto the bare board. This solder paste is thin and its made of stainless-steel. The pieces have to sit on the PCB in the areas where the paste is applied.

Pick and Place

Picking as well as placing the components comes after the assemblers have finished soldering. This is mostly accomplished through using a one-of-a-kind robotic machine. Although, this is possible by hand, machines outperform humans in terms of accuracy.

Reflow Soldering

Once your solder paste as well as the components is properly positioned, they must remain there. Assemblers have to make sure the paste solidifies in order for it to work with the board’s components. Fortunately, you can achieve this with reflow soldering.

Quality Control and Inspection

After reflow soldering, then this circuit board must be inspected for good quality control. The board’s functionality is tested during the inspection. The circuit board is inspected here for quality issues.

Functional tests and final inspection

Final tests come after the quality checks. These tests detect errors before the board is fully manufactured. The primary purpose of the tests is avoiding costly mistakes immediately the board is released to the public.

Soldering Equipment for Professional PCB Assembly

For manual pcb assembly, you can select from a variety of soldering equipment. The most basic ones plug directly into a power outlet, which don’t have many temperature control options. For your professional PCB assembly, you should use a soldering iron with a power range of 15 to about 30 watts.

The soldering irons that are thermostatically controlled, which have temperature control options, may be suitable. Some have temperature dials, while others make use of magnetized tip having a preset temperature.

This would be advantageous if you used soldering irons with different replaceable tips having various sizes. As the current flow increases, the bonuses start to magnetize, leading to a rise in temperature. When magnetism decreases, heat decreases as well.

A hot soldering station, which makes use of hot air in melting the solder, may also be required.

Inspecting and Testing of PCB Assemblies

Nothing is more inconvenient than ordering a faulty PCB that will not function properly in the electronic devices. In order to be safe, make sure that your PCBs have been tested and inspected for functionality. Also, as a pcb manufacturer, you would want to avoid having to do the PCB manufacturing over again. You’ll accomplish this by inspecting and testing your PCBs before their release into the market. Also, you must submit the boards for DFM testing.

Depending on what your budget is, you can select between x ray inspection and manual checks when performing inspection and quality control.

- The best is X ray inspection, because it helps in inspecting the PCB features that are hidden.

- Manual testing is less expensive but might not produce the required results because humans are make errors.

- Finally, you may want to consider using AOI. This is a critical technique in the manufacture and testing of PCBs. AOI enables the rapid and accurate inspection of the electronic assemblies. This is to make sure of product quality.

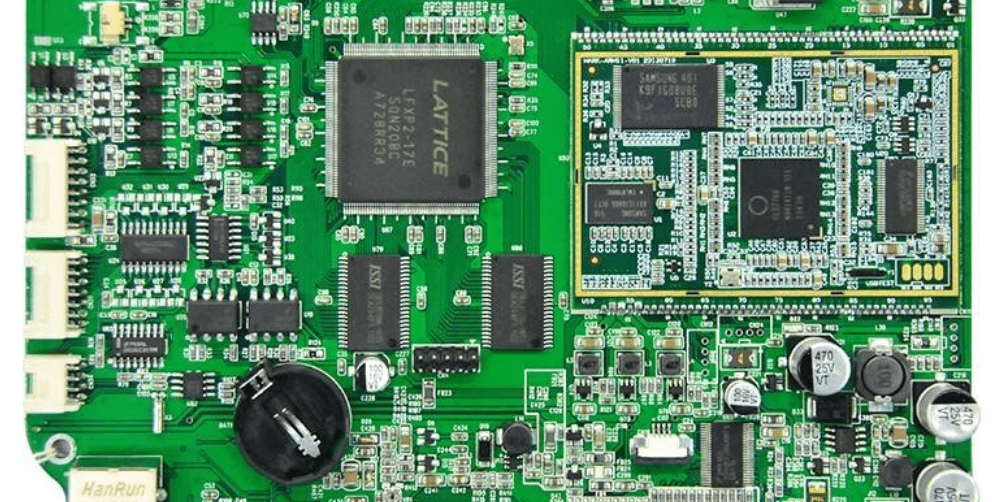

Differences Between the Through Hole and the SMT Assembly in Professional PCB Assembly

This section differentiates between through hole and the SMT assembly. When we finish this section, you will know which professional PCB assembly is best for you.

Differences in Spaces

Based on two factors, SMT allows for the easy mounting of more components. For starters, SMT elements are typically smaller. Second, these components are small enough to fit on the board’s two sides. With the chance of having some parts on the board’s two sides, space is an issue in through-hole technology.

SMT Assembly has a higher pin count than the Thru-Hole Technology.

SMT is different from the thru-hole technology in terms of pin count because SMT PCBs have more pins. Also, with the advancement of technology, there is a slight reduction in the number of leads accompanying thru hole technology.

The Components of SMT Assembly are typically less expensive than the thru-hole components.

The components of SMT assembly are a bit less expensive than the thru-hole pieces in terms of cost. When purchasing parts, you must pay additional fees if you choose through-hole technology. Again, this is one reason why so many people want to use SMT technology because it is simple to implement and uses inexpensive components.

Surface Mount Is More Beneficial in Assembly Automation

In contrast to PTH technology, SMT relies heavily on automation. This is why large batches of products can be produced. Manufacturing firms could save money on production costs by being able to produce large sets

PCB manufacturers would save much time with automated assembly, which they can put to better use. PTH technology is not great for automation, resulting in slow circuit board production for anyone that prefers it.

Performance is more important in thru-hole technology.

PTH technology has the advantage of producing panels, which can function properly in environments of high heat. PTH technology also, is known as a safe process that creates boards that can withstand vibrations and shocks. PTH-made boards can withstand any stressing condition easily.

The Cost Distinction between the Surface Mount and Through Hole

For sure, the PCB cost when manufactured using the PTH technology is different from those manufactured using SMT. The thru-hole drilling entails drilling the leads on the PCB to connect all of the whole components.

Drilling, as opposed to placing and picking pieces on the circuit board, takes time and money. Members might need to be manually soldered onto the circuit board at times. As a result, the cost of circuits manufactured using thru-hole technology is typically high.

Advantages of Professional PCB Assembly

Do you need to outsource circuit board assembly for your new project? Maybe you just need a few boards for testing. Or you may only need one prototype. Whatever the case, we have the service options to help you develop and test your product. These include manufacture, small batch production, and full production runs.

If you don’t want to deal with the hassle of assembling your circuit boards, you should really consider using a PCB assembly service. Doing so can provide some great benefits like enabling you to focus on what you do best.

High-Quality Construction and Materials

One thing you can depend on whenever you are working with an expert printed circuit assembly company is that they will make use of the best tools and materials for the job. With reputable companies that have been in business for many long years, this is generally true. But if you want to ensure there’s no flaw in your final product, choose a company that provides the best assembles possible.

Early detection of errors

Even the most experienced printed circuit board designers might make mistakes. If this mistake is repeated on all the circuit boards manufactured, it could result in a huge loss for your company. It’s a problem you don’t want to allow to happen to your business – but if it does, you can outsource the assembly to a professional.

At Hillman Curtis, we’ll test your design after you’ve tested it to make sure there aren’t any mistakes down the road. This will give you the confidence you need to proceed with full production and with certainty that your product will work correctly when put together.

Saves Time

Take a look at the amount of time spent when manufacturing and assembling all the PCBs in-house. To meet the assembly and manufacturing needs, you would need to hire more people. It would consume a significant amount of time, which could be better spent on working the different aspects of the business. Hiring professionals for pcb assembly makes far more sense. They can handle the assembly if you only need just a PCB or thousands of them.

Lower Manufacturing Costs

Consider manufacturing costs, which would be incurred if the boards are assembled yourself. A larger space would be required for the professional pcb assembly. You’d have to purchase all the tools and materials required, plus more.

You can speak with some companies like Hillman Curtis to have an estimate of the amount the PCBs will cost. When comparing this to the cost involved in the expansion of your facility as well as hiring extra people for professional pcb assembly, you’ll understand why it is a great idea to outsource.

Turnaround time may be faster

Some companies consider in-house pcb assembly because they are concerned that a different company won’t assist them meet their deadlines. However, this isn’t usually the case. In many cases, if you select a company known for its quick turnaround time, then you can have the circuit boards within days. Of course, this depend on how many PCBs are required and the assembly company you select.

Choose Hillman Curtis for your Professional PCB Assembly Requirements.

Naturally, you’ll want to make certain that you’re only getting the best service for professional PCB Assembly or printed circuit board assembly. Also, you should think about what this company has to offer as well as how quickly they can deliver the finished boards to you. Price is, of course, another consideration.

You wish to work with a reputable company that is both affordable and capable of providing excellent customer service.

Also, now that you’ve learned more concerning the advantages of hiring an expert for pcb assembly, it’s high time to get a company, which can meet your needs. From start to finish, we at Hillman Curtis work hard to provide the best products and service to our customers.

We can assist you whether you only require a prototype, or a large quantity of boards. Contact us right away.

Comments are closed