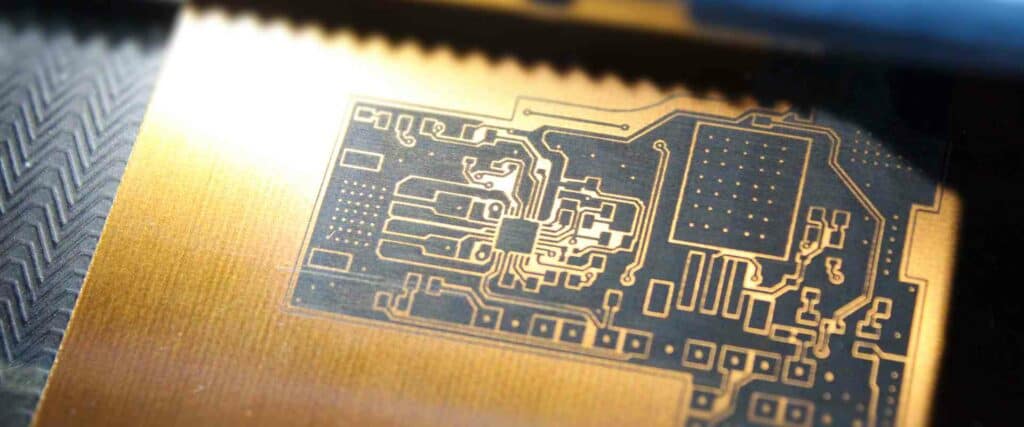

Laser engraving has become a popular method for creating circuit boards due to its precision and efficiency. This process involves using a laser to etch the circuit board pattern onto a copper-clad board. The laser removes the copper in the areas where the circuit will be created, leaving behind the desired pattern.

Laser engraving offers several advantages over traditional methods of creating circuit boards. For one, it allows for greater precision and accuracy, resulting in higher quality boards with fewer errors. Additionally, laser engraving is a faster process than traditional methods, making it a more efficient option for producing circuit boards in large quantities. Overall, laser engraving is a reliable and effective method for creating circuit boards that meets the demands of modern technology.

High Density Interconnect (HDI) PCB is a type of printed circuit board that is designed to have a higher wiring density than traditional PCBs. HDI PCBs are used in a wide range of applications, including smartphones, tablets, and other portable electronic devices. They are also used in high-performance computing systems, aerospace, and medical devices.

What is Laser Engraving Circuit Boards?

Laser engraving circuit boards is a process of using a laser to selectively remove the copper layer on a printed circuit board (PCB) to create a custom circuit design. The process involves using a computer-aided design (CAD) software to create the desired circuit pattern. The laser then removes the copper layer, leaving behind the desired pattern.

Laser engraving circuit boards is a precise and efficient way to create custom circuit designs. The laser can remove the copper layer with high accuracy, allowing for intricate and detailed designs to be created. This process is also faster than traditional methods of creating circuit boards, such as etching, which can take several hours.

One of the advantages of laser engraving circuit boards is that it can be used to create small, complex designs that are difficult to achieve with traditional methods. The laser can also be used to create multiple layers on a single board, allowing for more complex circuits to be designed.

Overall, laser engraving circuit boards is a valuable tool for creating custom circuit designs quickly and accurately. It is an ideal solution for small-scale production runs and prototyping.

Advantages of Laser Engraving Circuit Boards

Precision and Accuracy

One of the most significant advantages of laser engraving circuit boards is the precision and accuracy it offers. Laser engraving technology allows for intricate and precise designs to be engraved onto circuit boards with high accuracy, unlike traditional methods. This precision is essential when designing circuit boards with small components and tight tolerances.

Laser engraving machines use advanced software and hardware to ensure that the design is engraved exactly as intended. This accuracy reduces the risk of errors and ensures that the circuit board functions correctly.

Versatility

Laser engraving technology is incredibly versatile and can be used to engrave a wide range of materials, including metal, plastic, and even wood. This versatility makes it an ideal solution for engraving circuit boards made from different materials.

Laser engraving technology can also be used to engrave a wide range of designs onto circuit boards, including logos, serial numbers, and other identifying information.

Cost-Effective

Laser engraving circuit boards can be a cost-effective solution compared to traditional methods. The precision and accuracy of laser engraving technology reduce the risk of errors, which can save time and money in the long run.

Laser engraving machines also require minimal maintenance and have a long lifespan, making them a cost-effective solution for businesses and individuals.

Efficiency

Laser engraving technology is incredibly efficient and can engrave circuit boards quickly and accurately. This efficiency reduces the time required to produce circuit boards, which can be beneficial for businesses that require a high volume of circuit boards.

Additionally, laser engraving technology is computer-controlled, which means that it can be easily programmed to engrave a wide range of designs onto circuit boards without the need for manual labor.

In summary, laser engraving technology offers several advantages for engraving circuit boards, including precision and accuracy, versatility, cost-effectiveness, and efficiency.

How to Laser Engrave Circuit Boards?

Preparing the Circuit Board

Before you start laser engraving your circuit board, you need to prepare it. Here are the steps you should follow:

-

Clean the circuit board: Use a cloth to clean the circuit board and remove any dirt or dust particles.

-

Apply a layer of spray paint: Apply a thin layer of spray paint on the circuit board. This will help the laser engraving machine to create a contrast between the engraved and unengraved areas.

-

Print the design: Print the design of the circuit board on a piece of paper. Place the paper on top of the circuit board and align it properly.

-

Transfer the design: Use a transfer paper to transfer the design from the paper to the circuit board. Make sure the design is transferred accurately.

Setting Up the Laser Engraving Machine

Once the circuit board is prepared, you need to set up the laser engraving machine. Follow these steps:

-

Select the right settings: Choose the right settings for the laser engraving machine. This includes the power, speed, and frequency.

-

Align the circuit board: Align the circuit board properly on the laser engraving machine. Make sure it is secured in place.

-

Focus the laser: Adjust the focus of the laser so that it is focused on the circuit board. You can do this by moving the laser up and down.

Engraving the Circuit Board

Now, you are ready to engrave the circuit board. Here are the steps you should follow:

-

Start the engraving process: Start the engraving process on the laser engraving machine. Make sure you are using the right settings.

-

Monitor the engraving: Monitor the engraving process to ensure that it is going smoothly. If there are any issues, stop the engraving process and make the necessary adjustments.

-

Remove the circuit board: Once the engraving is complete, remove the circuit board from the laser engraving machine. Clean it with a cloth to remove any debris.

By following these steps, you can laser engrave your circuit board with ease and precision.

Materials Required for Laser Engraving Circuit Boards

Laser Engraving Machine

The first and most important material required for laser engraving circuit boards is a laser engraving machine. There are many different types of laser engraving machines available, but not all of them are suitable for circuit board engraving. It is important to choose a machine that has a high enough resolution to accurately engrave the fine details of the circuit board. A machine with a minimum resolution of 1000 dpi is recommended.

Circuit Board

The second material required for laser engraving circuit boards is the circuit board itself. The circuit board should be made of a material that can be easily engraved by a laser, such as copper or aluminum. It is important to choose a circuit board that is the correct size and thickness for the project at hand.

Software

The third material required for laser engraving circuit boards is software. The software is used to create the design that will be engraved onto the circuit board. There are many different software programs available for this purpose, but it is important to choose one that is specifically designed for circuit board engraving. Some popular software programs for circuit board engraving include Eagle PCB and Altium Designer.

Protective Gear

The fourth and final material required for laser engraving circuit boards is protective gear. Laser engraving can be dangerous if proper safety precautions are not taken. It is important to wear protective gear such as safety glasses and gloves to protect yourself from the laser and any chemicals used in the engraving process.

In summary, the four materials required for laser engraving circuit boards are a laser engraving machine, circuit board, software, and protective gear. It is important to choose high-quality materials and take proper safety precautions to ensure a successful and safe engraving process.

Tips for Laser Engraving Circuit Boards

Choose the Right Laser Engraving Machine

When choosing a laser engraving machine, it is important to consider the size and power of the machine. The size of the machine should be able to accommodate the size of the circuit board you want to engrave. The power of the machine should be sufficient to engrave the material you have chosen. It is recommended to use a machine with a minimum power of 40 watts.

Select the Right Material

The material you choose for your circuit board should be able to withstand the laser engraving process. It is recommended to use materials such as FR-4, G-10, or CEM-1. These materials are commonly used in the production of circuit boards and are suitable for laser engraving.

Adjust the Settings

Before engraving the circuit board, it is important to adjust the laser settings to ensure the best results. The laser power, speed, and frequency should be adjusted according to the material being engraved. It is recommended to start with a low power setting and gradually increase the power until the desired result is achieved.

Ensure Proper Ventilation

Laser engraving can produce harmful fumes and particles. It is important to ensure proper ventilation in the workspace to prevent exposure to these harmful substances. A ventilation system should be installed to remove the fumes and particles from the workspace.

Wear Protective Gear

When laser engraving circuit boards, it is important to wear protective gear to prevent exposure to harmful fumes and particles. Protective gear such as a respirator, safety glasses, and gloves should be worn at all times during the engraving process.

By following these tips, you can achieve high-quality laser engraving results on your circuit boards.

Comments are closed