Many different metals can be used to create printed circuit boards (PCBs). Printed circuit boards with a metal core are these unique PCBs (MCPCBS). Typically, the type of metal is determined by the application. One of the common types of metal MCPCBS that are used in many contemporary applications is aluminum PCBs.

These PCBs have laminates made of copper and metal. The circuit board is a superior thermal and electrical conductor thanks to this design. Additionally, it assists the PCB in providing high performance. We will go into great detail about aluminum printed circuit boards in this article. The post also discusses the production process for these PCBs and the uses for these circuit boards. To learn more, keep reading.

What is an Aluminum PCB?

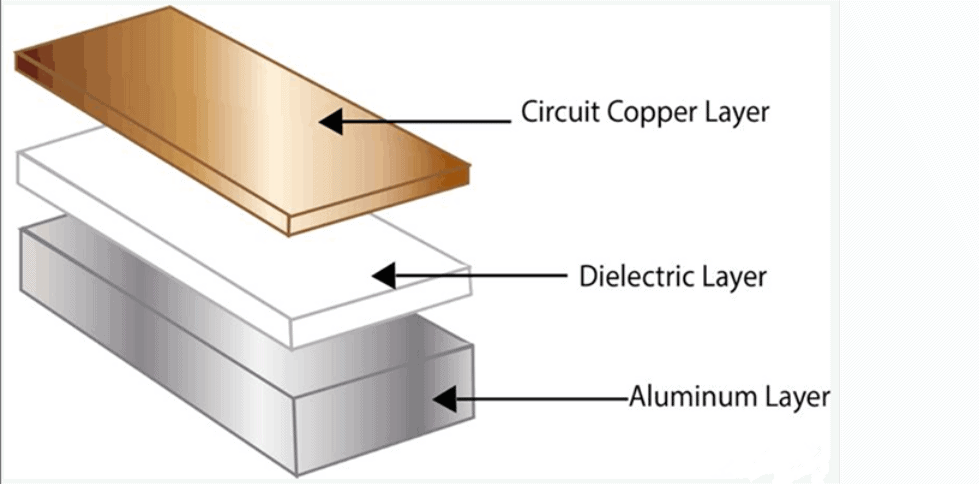

The layout of the aluminum PCB is the same as that of other PCBs. Over it are one or more copper layers, silkscreen, and solder mask. However, aluminum circuit boards features a unique metal substrate rather than a fiberglass or plastic one. Aluminum is the main component of this base. This metal core may be made of metal entirely or may include aluminum and a fiberglass composite. Although they could be two sided, aluminum PCB is typically single sided. The manufacturing of multilayer aluminum PCB is extremely challenging.

Majority of power conversion and LED electronics make use of aluminum boards. Also, aluminum directs heat from components due to the intense light that LEDs produce. The aluminum PCB increases the stability as well as life of the LED device. Aluminum substrates are used in household lighting, stop lights, as well as street lighting. They enable electronic regulation and current switching in power converters. Aluminum PCBs are used by designers in numerous other industries, but they are not used as frequently.

What Kinds of Aluminum PCBs Are There?

As previously stated, deciding on the aluminum printed circuit board type has to do with the application. Following are the three primary categories of aluminum PCBs:

Through Hole Aluminum PCBs

The aluminum is pre-drilled in through-hole aluminum circuit boards. A dielectric is then back-filled into the hole after that.

Flexible Aluminum PCBs

Flexible dielectrics, which offer high flexibility levels, thermal conductivity, as well as electrical insulation, are used in these PCBs. When these dielectrics are combined with aluminum, a highly flexible product that can take many different forms is created. This helps get rid of pricy fixtures and connectors.

Hybrid Aluminum PCB

These aluminum PCBs are typically used in RF applications and have a reputation for offering better thermal performance when incorporated into FR4-compliant products.

Why Are Aluminum PCBs Used in So Many Different Applications?

Aluminum boards are popular in a wide range of applications due to their many advantages. Here are a few advantages.

Lightweight

One of these PCBs’ biggest benefits is that. Metals don’t get much lighter than aluminum. As a result, it aids in giving the PCB additional strength and resilience.

Heat-Removing Capability

When crucial circuit board components are exposed to high temperatures, damage may result. Therefore, it is very important that you make use of a material having the ability to dissipate heat. This is to protect them from such harm. The material that has the ability to transfer heat from the critical board components, protecting them from potential damage, is aluminum.

Long lasting

Aluminum is known as a strong substance with excellent durability. By using aluminum circuit boards, the risk of accidental breakage when handling, production, or regular use is eliminated. It can give a product more strength compared to ceramic and fiberglass bases.

Environmentally responsible

Aluminum PCBs are simple to assemble, which promotes energy efficiency. In addition, the substance is non-toxic and recyclable. As a result, it is environmentally friendly and helps to protect the environment.

Economical

Aluminum can be found in almost any climate, making it simpler to mine and refine. Costs are lowered as a result. As a result, manufacturing with aluminum is less expensive than manufacturing with other metals.

Important Criteria to Consider When Choosing an Aluminum PCB Factory and Manufacturer

Regardless of where they are made, PCB manufacturing generally uses the same production process. The degree of automation in a supplier’s process, the use of cutting-edge technology and equipment, and the possession of equipment specifically made to focus on particular types of end products are the only real differences between suppliers.

Aluminum PCB

If a PCB manufacturer wants to effectively produce aluminum PCBs in any quantity, they must take into account a number of important factors, such as:

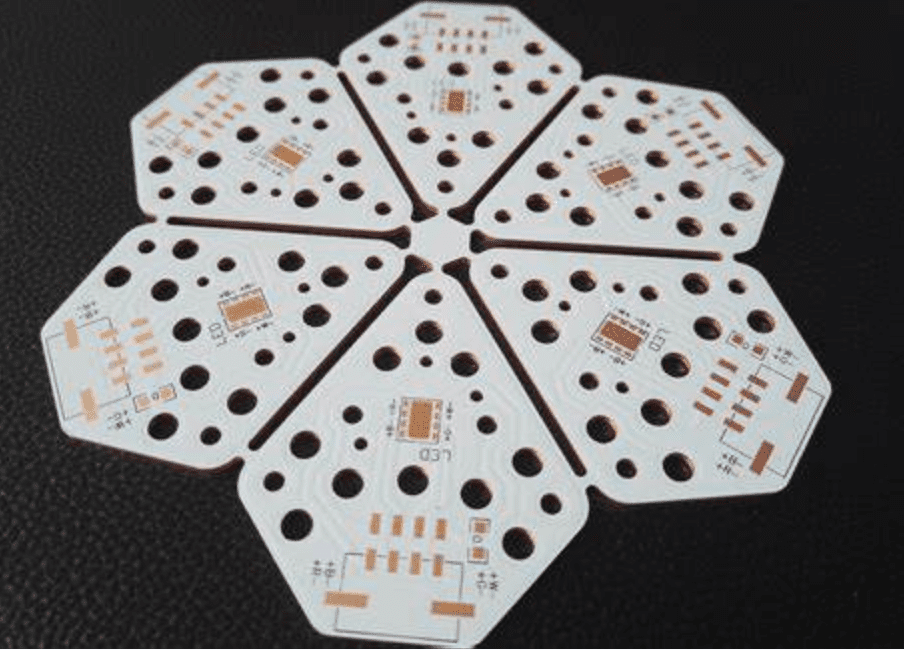

Equipment for Specialized Scoring

Aluminum PCBs cannot be managed with the more prevalent equipment that can V score through conventional FR-4 materials. We must be able to place these components as closely as possible to one another on the production panel in order to maximize yield and achieve the lowest cost.

Without V scoring, you would have to mechanically route the parts, which could reduce your yield by up to 20% and raise your cost.

For many years, our engineering team has worked with our customers to design arrays that will be the most affordable for them to depanelize.

More powerful punch presses than 40 tons

You need a manufacturer who can punch out these features if your aluminum PCB is round or have other special features, such as slots, big holes, cutouts, etc. In a production setting, trying to mechanically route aluminum PCBs is a very expensive way to implement these features.

Aluminum PCB Manufacturing Difficulties

Majority of aluminum PCBs are produced using the same method. Here, we’ll talk about the main manufacturing procedures, the challenges faced, and ways of overcoming them.

Copper Etching

In comparison, copper foil in aluminum PCB is thicker. After etching, its trace width would be outside of tolerance if it does not meet the design requirements.

Therefore, it is important to accurately design the compensation of trace width. Controlling the factors of etching during the manufacturing process is necessary.

Printing a solder mask

Aluminum PCB printing of the solder mask is challenging because of the copper foil that is thick. This is due to the fact that printing solder masks will be challenging if this trace copper becomes too thick and the etched image has a significant difference between the base board and trace surface.

Who are the Top Suppliers of Aluminum PCBs?

MOKO Technology

Aluminum PCBs are a product that MOKO has vast experience supplying to clients in various industries. The business employs a qualified team for engineering, production, and customer service. With respect to your project’s needs, MOKO’s aluminum PCB factory recommends the best solution as an authority on aluminum PCBs.

Each aluminum PCB is produced and assembled in-house by MOKO’s aluminum PCB factory, guaranteeing its high quality. All PCBs are subjected to a battery of inspections and tests prior to delivery, including automatic optical inspection, x-ray inspection, and functional test, as part of our strict quality control procedures. Using MOKO can protect you from poor quality issues.

MOKO manufactures aluminum PCBs with industry-leading technology and cutting-edge machinery that significantly boosts productivity. The company can produce products quickly for prototyping, low-volume, high-volume production, and everything in between. Additionally, they collaborate with trustworthy shipping companies to guarantee delivery on time.

RayMing PCB & Assembly

RayMing PCB & Assembly with more than ten years of experience in the electronics manufacturing sector, this company, which was founded back in 2005, specializes in providing high-quality PCB Assembly, PCB Fabrication, as well as component sourcing, to businesses. RayMing is a skilled manufacturer of aluminum PCB boards as well.

The business is also among the best suppliers and manufacturers of aluminum PCBs. They also offer double-sided and multilayer circuit boards and participate in PCB assembly.

Additionally, the company has an aluminum PCB factory that offers high-quality PCB assembly, component sourcing, and PCB fabrication to other nations. They have also worked in the field of electronic manufacturing for more than ten years.

Another reason RayMing technology has become one of the best today is their unwavering dedication to providing excellent customer service, combined with the tremendous expertise of their team.

Venture Electronics

Due to this aluminum PCB factory 100% quality guaranteed policy, this has earned the trust of thousands of electronic engineers worldwide. This makes Venture the ideal choice for your aluminum PCB needs. From single layer aluminum boards to six layer aluminum boards, Venture has complete technical knowledge and manufacturing experience in aluminum PCBs.

When it comes to various LED lighting projects, this company’s aluminum PCB factory is very active. They achieve this by using LEDs with a base material of the LED PCB made of copper foil, FR4, CEM3, or another type of metal substrate besides aluminum.

Making aluminum PCB boards for use in car or vehicle lights, medical lighting, street lights, spot lights, cabinets, wall lights, ground lights, desk lights, down lights, display lights, commercial lighting, and pendant lights is a great idea for this aluminum pcb factory.

ABIS Circuits

This manufacturer of aluminum PCBs was founded in 2006. Their products are very helpful in a variety of industries, including security, medical, consumer, industrial control, and telecommunication.

Additionally, the company offers PCB assembly, components sourcing, one-stop service, burn-in, housing, PCB soldering, and more services and goods. Their aluminum PCB factory also has outstanding market successes, including the use of their products across various industries. Additionally, they have 30 different countries represented among their clientele.

Additionally, they have more than 15 years of experience, and they typically export their goods to the USA and Europe.

Hillman Curtis

Hillman Curtis is renowned as a skilled and knowledgeable supplier of aluminum PCBs. They provide a one-stop shop that handles PCB design, production, assembly, testing, and housing.

Their goods are very useful in a variety of industries. These include the following industries: aerospace, digital communications, industrial control, medicine, and automobiles. In addition, this business has a reputation for on-time delivery thanks to its more than 18 years in the EMS industry.

Hillman Curtis’ aluminum PCB factory can offer partial and full turnkey pcb assembly services. They also offer PCBA testing, procuring the components, monitoring the quality at all times, and then the final assembly.

Advanced Circuitry International

This leading manufacturer of aluminum PCBs was established in 1992 and specializes in producing rigid, high-reliability PCBs for RF/microwave, antenna, and other applications.

Additionally, the telecommunications, aerospace, defense, and medical device industries can all benefit from their printed circuit boards. Along with having facilities that provide high-quality services and products and updated technologies and equipment, it also has highly qualified and experienced staff. You can rely on them to provide top-notch aluminum PCBs.

Imagineering, Inc.

Imagineering, Inc. is frequently chosen by American businesses as their preferred location for PCB manufacturing, particularly aluminum PCB. The 1986-founded business specializes in both the fabrication and assembly of various PCBs. Prototypes and PCBs suitable for production are among them.

Aside from offering excellent services, this company’s aluminum PCB factory also has small components, highly qualified experts, and distinctive tolerance guidelines. This will guarantee a high-quality, functional PCB.

What are the Applications of the Aluminum PCB

A good thermal dissipation function exists in aluminum bases. Due to the LED’s high heat output, the printed circuit board for LED lamps is typically made of aluminum substrate.

- Audio gear, including preamplifiers, input and output amplifiers, balanced amplifiers, audio amplifiers, and power amplifiers.

- Power supply accessories, such as stabilizers, conditioners, and DC-AC adapters.

- Electronic communication tools, such as electrical circuits for filters and high-frequency amplifiers.

- Automatic office equipment, such as motor drivers.

- Computer: motherboard, floppy drive, power supply, and other components.

- Power modules, such as rectifier bridges, solid relays, and inverters.

- Relays, transistor bases, and other circuit components used for electronic control.

- Switches, microwaves, thermal insulation, semiconductors, and motor controllers.

- Industrial vehicles: lighting conversion system, automatic safety control system, voltage regulator, ignition.

- LED Screen (two modes: LED display; display with LED light source)

- Lighting: As energy-saving lamps are promoted, the market has embraced a variety of energy-saving LED lights, which has led to widespread use of aluminum substrates for LED lights.

Conclusion

Working with the best aluminum PCB factory is the most appropriate move to achieving top notch aluminum PCBs. Work with us at Hillman Curtis today to get the very best from our Aluminum PCB factory.

Comments are closed