Flexible PCBs have revolutionized the electronics industry, making it possible to create compact and lightweight electronic devices. These circuit boards are designed to bend and flex, making them ideal for use in applications where space is limited. One such application is LED strip lighting, where flexible PCBs are used to power and control the individual LED lights.

LED strip lighting has become increasingly popular in recent years, thanks to its versatility and energy efficiency. These strips can be used for a wide range of applications, from accent lighting to task lighting. However, powering and controlling the individual LEDs can be a challenge, particularly in applications where space is limited. This is where flexible PCBs come in, providing a compact and reliable solution for powering and controlling LED strip lighting.

Flexible PCBs for LED strip lighting come in a variety of shapes and sizes, making it possible to customize the design to meet the specific needs of each application. These circuit boards are designed to be easy to install and maintain, making them an ideal choice for both DIY enthusiasts and professional installers. With the growing popularity of LED strip lighting, flexible PCBs are likely to become even more important in the years to come.

What is a Flexible PCB?

Flexible PCB, also known as a flex circuit or flex PCB, is a type of printed circuit board designed to fit and bend to different shapes and sizes. It is made up of a thin, flexible plastic substrate material that can be rolled, folded, or twisted to fit into tight spaces or conform to the shape of a product.

Construction

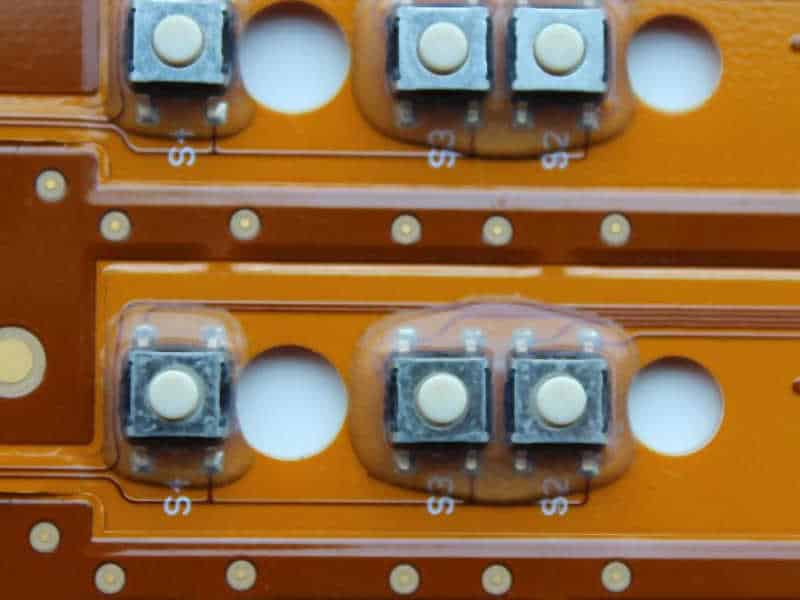

Flexible PCBs are constructed using a flexible substrate material, such as polyimide or polyester film, which is coated with a layer of conductive material, such as copper. The conductive layer is then etched to create a pattern of traces and pads that connect the components on the board.

The flexible substrate material is then layered with an insulating material, such as a coverlay or solder mask, to protect the conductive layer from damage and prevent short circuits. The finished flexible PCB can be single-sided, double-sided, or multi-layered, depending on the complexity of the circuit.

Benefits of Using a Flexible PCB

Flexible PCBs offer several benefits over traditional rigid PCBs, including:

-

Flexibility: Flexible PCBs can be bent, folded, and twisted to fit into tight spaces or conform to the shape of a product, making them ideal for use in products with irregular shapes or limited space.

-

Weight and Size Reduction: Flexible PCBs are thinner and lighter than rigid PCBs, which can reduce the overall weight and size of a product.

-

Increased Reliability: Flexible PCBs can withstand more vibration and shock than rigid PCBs, which can improve the reliability of the product.

-

Cost Savings: Flexible PCBs can be more cost-effective than rigid PCBs, especially for small or complex circuits, as they require fewer components and less assembly time.

Overall, flexible PCBs are a versatile and reliable solution for a wide range of electronic devices, from LED strips to medical equipment.

LED Strip Lighting

Overview

LED strip lighting is a type of lighting that is flexible and can be easily installed in a variety of settings. It consists of a flexible printed circuit board (PCB) with small LED lights attached to it. The LED lights are available in a variety of colors, and the strip can be cut to fit the desired length.

LED strip lighting is commonly used for accent lighting, under-cabinet lighting, and backlighting. It is also popular for use in display cases, shelves, and other areas where traditional lighting may not be practical.

Benefits of LED Strip Lighting

LED strip lighting offers several benefits over traditional lighting options. Some of these benefits include:

-

Energy efficiency: LED lights use less energy than traditional lighting options, which can lead to significant energy savings over time.

-

Longevity: LED lights have a longer lifespan than traditional lighting options, which can lead to less frequent replacements and maintenance.

-

Flexibility: LED strip lighting is flexible and can be easily installed in a variety of settings, making it a versatile lighting option.

-

Customization: LED strip lighting is available in a variety of colors and can be cut to fit the desired length, allowing for customization to fit specific needs.

-

Safety: LED lights produce less heat than traditional lighting options, which can reduce the risk of fire or other safety hazards.

Overall, LED strip lighting is a versatile and energy-efficient lighting option that offers several benefits over traditional lighting options.

Using a Flexible PCB for LED Strip Lighting

When it comes to LED strip lighting, using a flexible PCB can provide many benefits. In this section, we will discuss the advantages of using a flexible PCB for LED strip lighting and how to choose the right one for your needs.

Advantages of Using a Flexible PCB for LED Strip Lighting

-

Flexibility: As the name suggests, flexible PCBs are designed to be flexible, making them ideal for use in applications where the strip lighting needs to be bent or curved. This flexibility also makes it easier to install the LED strip lighting in tight or awkward spaces.

-

Durability: Flexible PCBs are made from high-quality materials that are designed to withstand harsh environments and extreme temperatures. This makes them ideal for use in outdoor applications where the LED strip lighting may be exposed to rain, snow, or other weather conditions.

-

Cost-effective: Using a flexible PCB can be more cost-effective than using traditional PCBs because they require less material and are easier to manufacture.

How to Choose the Right Flexible PCB for LED Strip Lighting

When choosing a flexible PCB for LED strip lighting, there are several factors to consider:

-

Size: The size of the flexible PCB will depend on the size of the LED strip lighting you are using. Make sure to choose a flexible PCB that is the right size for your needs.

-

Number of Layers: The number of layers in a flexible PCB will affect its performance and durability. Make sure to choose a flexible PCB with the right number of layers for your needs.

-

Material: The material used to make the flexible PCB will affect its durability and flexibility. Make sure to choose a flexible PCB made from high-quality materials that are designed to withstand harsh environments.

In conclusion, using a flexible PCB for LED strip lighting can provide many benefits, including flexibility, durability, and cost-effectiveness. When choosing a flexible PCB, make sure to consider factors such as size, number of layers, and material to ensure that you choose the right one for your needs.

Installation and Maintenance

Installation Process

Installing flexible PCBs for LED strips is an easy process that can be done with a little bit of patience and attention to detail. Here are the steps to follow:

- Measure the length of the area where you want to install the LED strip and cut the PCB to the desired length.

- Clean the surface where you will install the strip to ensure there is no dust or debris that could affect the adhesive.

- Peel off the protective layer of the adhesive tape on the back of the PCB and carefully place it on the cleaned surface.

- Connect the LED strip to the PCB by soldering the wires to the designated solder pads.

- Test the LED strip to ensure it is working correctly.

Maintenance Tips

Maintaining flexible PCBs for LED strips is essential to ensure their longevity and optimal performance. Here are some tips to keep in mind:

- Avoid bending or twisting the PCB as it can damage the copper traces and affect the LED strip’s performance.

- Keep the PCB and LED strip clean by wiping them with a dry cloth to remove any dust or debris that may accumulate over time.

- Do not expose the PCB and LED strip to extreme temperatures or humidity as it can cause damage to the components.

- Check the connections periodically to ensure they are secure and functioning correctly.

- In case of any damage or malfunction, replace the PCB or LED strip immediately to avoid further damage.

By following these installation and maintenance tips, you can ensure that your flexible PCBs for LED strips are working correctly and have a long lifespan.

Comments are closed