PCB is the heart of every electrical and digital device. It is almost impossible to avoid dirty PCB. PCB accumulates dust and grime over time. Sometimes acid splashing leads to the corrosion of delicate joints and parts. In some cases, overheating also causes damage to the tiny parts and sometimes the melting of parts. That’s why it also affects the functionality of the device. It is necessary to keep PCB clean and in proper working condition. Let’s dig deeper to learn more about dirty printed circuit boards and how you can keep them clean without spending an extra amount.

Factors t contributing to making PCB dirty

Following factors not only make the PCB dirty but also affect its functionality.

Dust and moisture

Dust and moisture are the main culprits. The dust has tiny particles that go deeper inside the board. Dust can cause several problems with a circuit board. It has tiny particles that can accumulate on tiny circuits and joints. It can make a film on the surface that affects functionality. This thin dusty film can increase the resistance and friction between the parts. Sometimes dust and moisture both become problematic for the circuit board. They promote corrosion. Furthermore, since they can also interpret the proper functioning of signal interference in the printed circuit board, it is necessary to inspect your equipment on a permanent basis for cleaning.

Flux residue and overheating

Flux residue and overheating are other reasons for damage, and dirty PCB. It has hydrophilic properties. So, any mistake during assembly can cause flux residue. During soldering or any other materials, heat up during assembly and can produce steam or gas. Later it creates a pathway for dust and other pollutants.

Harsh full environment

Harsh full environment or working conditions PCB’s working environment also affects their functionality. Extra resistance and heat dissipation affect the tiny parts. Similarly, heating can lead to the melting of tiny parts. Sometimes, you have to replace the PCB for proper functioning.

Acid splashing

Sometimes acid splashing plays an important role in wear and tear. PCBs consist of delicate and tiny a part that’s why they need to operate with care. Ignoring the instruction regarding the usage of PCB can lead to problems. If you put the device or machine in a place where air and moisture can get easily in the machine, then there is more chance of dirty PCB. Sometimes this moisture leads to the permanent erosion of tiny parts and circuits.

Simple Ways to clean a dirty PCB

There are different ways to clean PCB, but remember, it is tricky and hard. Some devices are simple and easy to open to get PCB out for cleaning. At the same time, some devices are complex and hard to get cleaned. It’s not easy to clean a printed circuit board for the layman. If you are ignorant of basic cleaning steps and need to learn more about PCBs, then don’t do it yourself. You know that PCBs consist of delicate parts. Unprofessional hands can ruin a dirty PCB instead of cleaning it.

First of all, open the machine or device and look at the condition Of the PCB. It is necessary to know whether PCB requires deep cleaning or basic cleaning.

Basic cleaning with tooth brush

If there is light dust or debris, then you can easily remove it. A tiny toothbrush can do this job so easily. It is little and lightweight enough for comfortable handling. It has fine bristles to clean the smallest particles. No dust cloth and other brush can do this job so perfectly. So you don’t need any fancy cleaning tools.

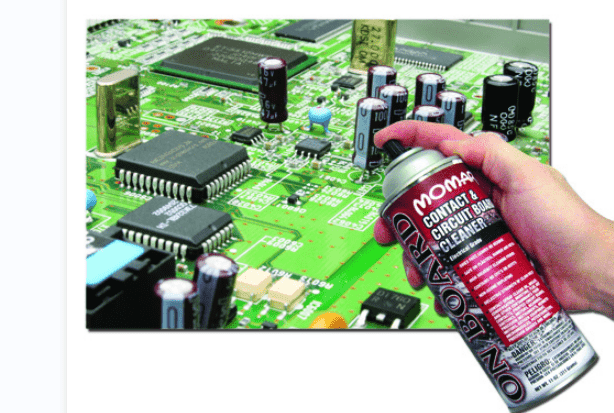

Grime cleaning with alcohol

Similarly, Some PCBs are dirty due to grime. Grime is formed when the dust is mixed with moisture, acid, or oil. In this way, dust made a sticky thin film on the board. Anhydrous alcohol can help in cleaning tiny electronic components in the printed circuit board. It is a better option compared to ordinary alcohol. Specific printed circuit board cleaners are available in the market if you have some money to buy these cleaners.

Baking soda paste to remove corrosion or rust

Acid splash and saltwater is the reason for corrosion. That’s why PCB doesn’t perform properly, so it is necessary to remove the corrosion for the proper working of PCB. You can make baking soda paste and simply apply it to the affected areas. Leave it for a while. Later remove this paste with a smooth cloth. You can use the commercially available neutralizing paste on the areas of acid damage.

Tips to avoid the dirty PCB

The ideal environment for a printed circuit board is free of dust, dirt, moisture, acids, flux residue, and other pollutants. However, it is impossible to keep your printed circuit board completely dust- free. Eventually, every PCB gets dirty enough to require cleaning.

- Keep the printed circuit board in the package or bubble sheet until your design is ready. In this way, you can avoid dust and other pollutants.

- Conformal coating can help you to protect your PCB. This protective coating keeps safe PCB from acid splash, salt water, and erosion. It also helps in reducing resistance.

- Further, you can place your device or machine away from direct contact with air and moisture. Proper heat dissipation in the machine can help in improved function of PCB., so it is also necessary to design the product intelligently.

- Last but not least. Preventive and regular cleaning can increase the life span of PCB. Furthermore, you don’t have to spend much time cleaning.

Wrapping up the things

PCB is the heart of any device or machine, so properly working is necessary. A dirty PCB can compromise the device’s efficiency. That’s why it is essential to keep your PCB neat. After a few months of use, you can clean your PCB by following the tips mentioned above. If you are not much into cleaning things or want to avoid the risk, you can get help from professional cleaners. They can easily clean the PCB and sometimes repair the demanded parts also.

Comments are closed