A programmable power supply PCB is a printed circuit board that is designed to provide a stable and adjustable voltage output to power electronic devices. These power supplies are commonly used in laboratories, manufacturing facilities, and other settings where precise and reliable power is required.

One of the key advantages of a programmable power supply PCB is its ability to be programmed to output a specific voltage, current, or power level. This allows users to tailor the power supply to meet the specific needs of their application, ensuring that their devices receive the correct amount of power for optimal performance.

Another benefit of programmable power supply PCBs is their compact size and portability. These power supplies can be designed to fit into a variety of form factors, making them ideal for use in applications where space is at a premium. Additionally, many programmable power supply PCBs are designed to be lightweight and easy to transport, making them an excellent choice for fieldwork or other applications where mobility is important.

What is a Programmable Power Supply PCB?

Overview of PCBs

Printed Circuit Boards (PCBs) are the backbone of modern electronics. They are the foundation on which all electronic devices are built. PCBs are used to connect and control electronic components, including microprocessors, memory chips, and sensors. They are designed to be durable, reliable, and efficient.

Overview of Power Supplies

A Power Supply is an essential component of any electronic device. It converts AC power from a wall outlet into DC power that is used to run the device. Power Supplies come in many different shapes and sizes, and can be designed to provide different levels of voltage and current.

What is a Programmable Power Supply PCB?

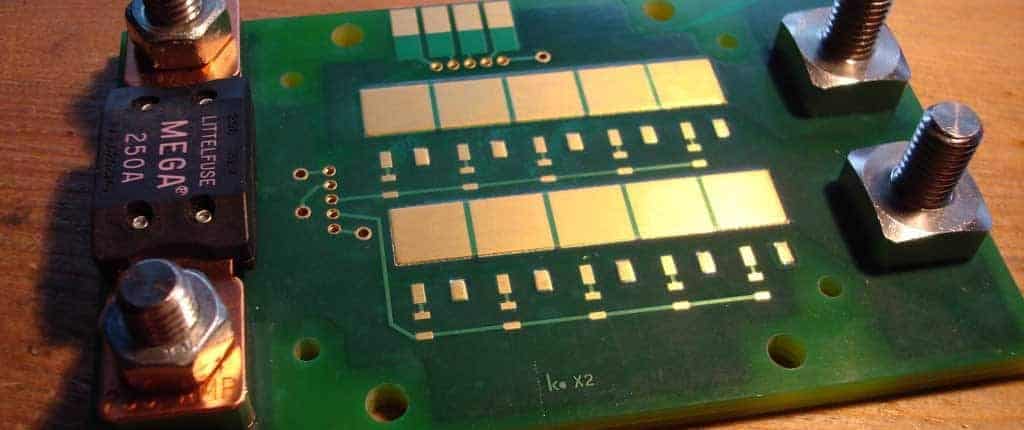

A Programmable Power Supply PCB is a type of PCB that is designed to provide precise, programmable voltage and current levels. It is used in a wide range of applications, including test and measurement equipment, medical devices, and industrial control systems.

A Programmable Power Supply PCB typically includes a microcontroller, voltage and current sensors, and power transistors. The microcontroller is used to control the voltage and current levels, while the sensors are used to measure the actual levels. The power transistors are used to regulate the voltage and current levels.

Advantages of Programmable Power Supply PCBs

There are several advantages to using a Programmable Power Supply PCB. First, it provides precise, programmable voltage and current levels, which is essential for many applications. Second, it is more efficient than traditional linear power supplies, which waste energy as heat. Finally, it is more reliable than traditional linear power supplies, which can be damaged by power surges and other electrical disturbances.

In summary, a Programmable Power Supply PCB is a type of PCB that is designed to provide precise, programmable voltage and current levels. It is used in a wide range of applications, including test and measurement equipment, medical devices, and industrial control systems. It offers several advantages over traditional linear power supplies, including greater efficiency and reliability.

Designing a Programmable Power Supply PCB

Overview of the Design Process

Designing a programmable power supply PCB requires careful planning and attention to detail. The process involves selecting the appropriate components, designing the schematic, creating the PCB layout, and testing and validating the final product.

Choosing Components

When selecting components for a programmable power supply PCB, it is important to consider factors such as voltage and current requirements, efficiency, and reliability. Some commonly used components include voltage regulators, capacitors, resistors, and transistors. It is also important to choose components that are compatible with the desired programming interface.

Schematic Design

The schematic design is a crucial step in the design process. It involves creating a diagram that shows how the various components will be connected and how they will function together. The schematic should be clear and easy to read, and it should accurately reflect the intended functionality of the power supply.

PCB Layout Design

The PCB layout design involves arranging the components on the board in a way that maximizes efficiency and minimizes interference. It is important to consider factors such as trace length, component placement, and signal integrity when designing the layout. The PCB layout should be optimized for manufacturability and should be easy to assemble and test.

Testing and Validation

Once the PCB design is complete, it is important to thoroughly test and validate the final product. This involves checking for errors and ensuring that the power supply meets the desired specifications. Testing should be done in a controlled environment to ensure accurate results.

Overall, designing a programmable power supply PCB requires careful planning, attention to detail, and a thorough understanding of the components and design process. By following these steps and using the appropriate tools and techniques, it is possible to create a high-quality, reliable power supply that meets the needs of your specific application.

Applications of Programmable Power Supply PCBs

Overview of Applications

Programmable power supply PCBs are used in a wide range of applications, from consumer electronics to industrial applications and research and development. These power supplies are designed to provide a stable and reliable power source for a variety of devices, and they can be programmed to meet specific requirements.

Industrial Applications

In industrial applications, programmable power supply PCBs are used to power a range of equipment, including motors, pumps, and other machinery. These power supplies can be programmed to provide a specific voltage or current output, and they can be configured to operate in a variety of environments. In addition, these power supplies are designed to be highly reliable and durable, making them ideal for use in harsh industrial environments.

Research and Development

In research and development, programmable power supply PCBs are used to power a range of experimental equipment, including sensors, data acquisition systems, and other devices. These power supplies can be programmed to provide precise voltage and current outputs, making them ideal for use in experiments that require a high degree of accuracy and repeatability.

Consumer Electronics

In consumer electronics, programmable power supply PCBs are used to power a range of devices, including smartphones, tablets, and laptops. These power supplies are designed to be compact and efficient, and they can be programmed to provide a specific voltage or current output that is tailored to the needs of the device. In addition, these power supplies are designed to be highly reliable and durable, making them ideal for use in consumer electronics devices that are subjected to frequent use and abuse.

Overall, programmable power supply PCBs are an essential component in a wide range of applications, providing a reliable and stable power source for a variety of devices. With their ability to be programmed to meet specific requirements, these power supplies are a versatile and valuable tool for engineers and designers across a range of industries.

Future of Programmable Power Supply PCBs

Emerging Technologies

As technology continues to advance, so does the potential for programmable power supply PCBs. One emerging technology is the use of gallium nitride (GaN) transistors, which offer higher efficiency and power density than traditional silicon-based transistors. Another technology is the use of artificial intelligence (AI) to optimize power supply performance and reduce energy waste.

Market Trends

The demand for programmable power supply PCBs is expected to grow as more industries adopt automation and digitalization. The automotive industry, for example, is increasingly using programmable power supplies in electric vehicles. The telecommunications industry is also a major user of programmable power supplies for network infrastructure.

Challenges

One challenge facing the programmable power supply PCB industry is the need for standardization. With so many different types of power supplies available, it can be difficult for manufacturers to ensure compatibility with different devices and systems. Additionally, the high cost of some emerging technologies may limit their adoption.

Opportunities

Despite these challenges, there are also opportunities for growth and innovation in the programmable power supply PCB industry. For example, the development of modular power supplies can allow for greater flexibility and customization. The use of renewable energy sources, such as solar power, can also create new opportunities for programmable power supplies in off-grid applications.

In conclusion, the future of programmable power supply PCBs looks promising as emerging technologies and market trends continue to drive growth and innovation. However, there are also challenges to be addressed, such as standardization and cost, in order to fully realize the potential of these advanced power supplies.

Comments are closed